Electric sweeping washing device

a washing device and electric technology, applied in the field of electric sweeping washing devices, can solve the problems of inability to wash and clean the floor thoroughly, and inability to remove tiny dust and smears from the floor or rug, etc., to achieve the effect of easy and fast cleaning of the floor and the rug, cost saving, labor saving and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

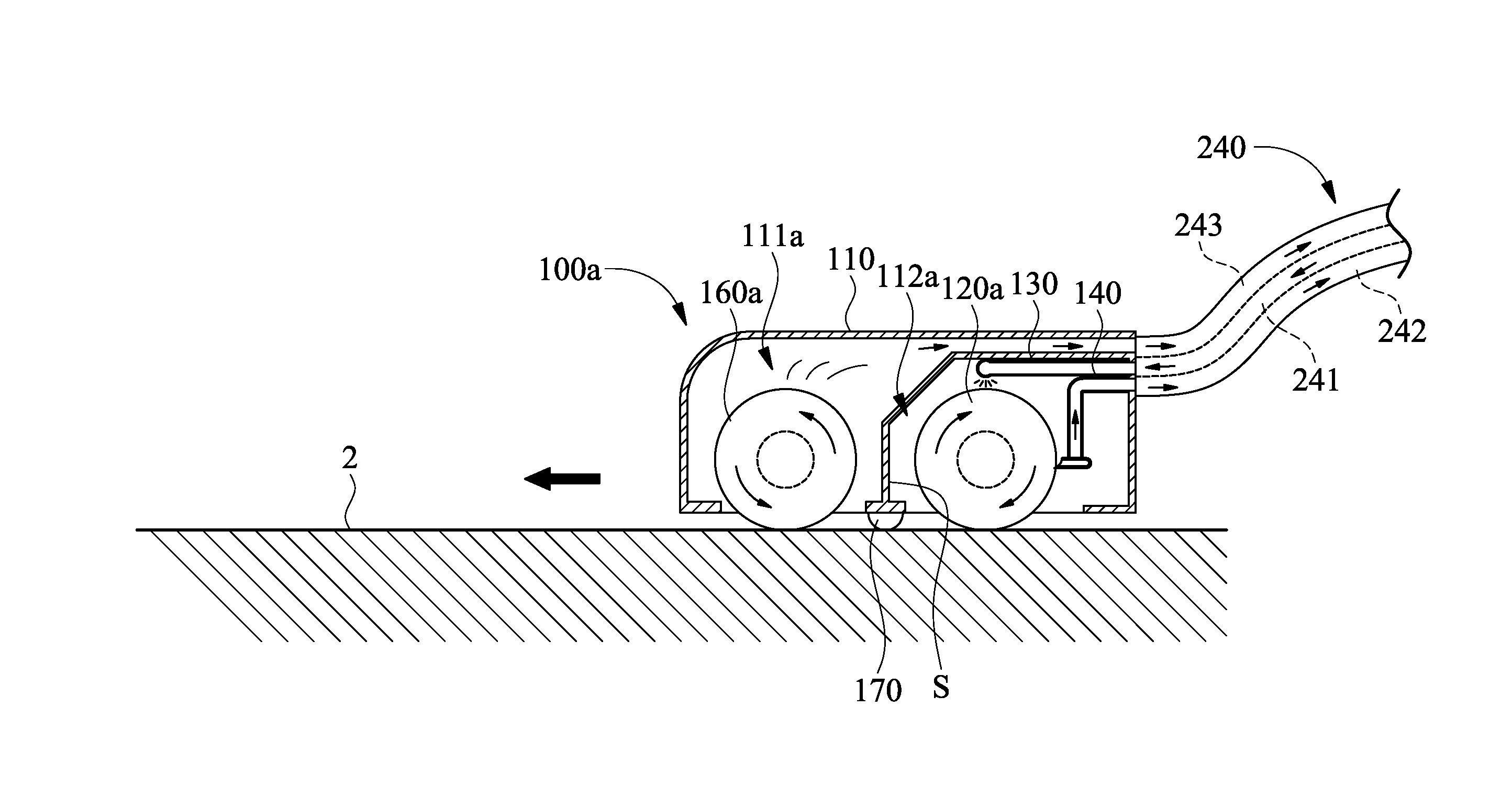

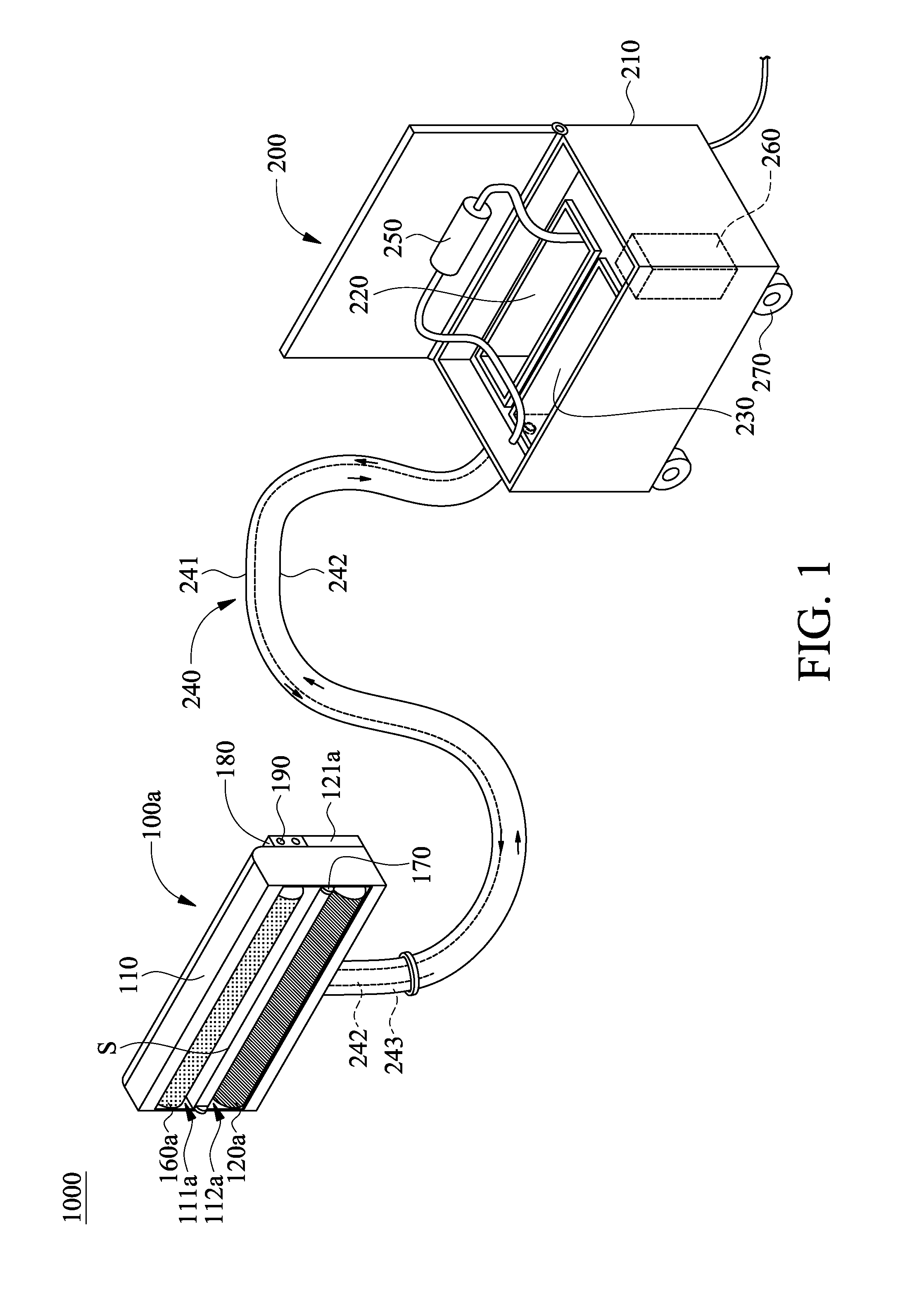

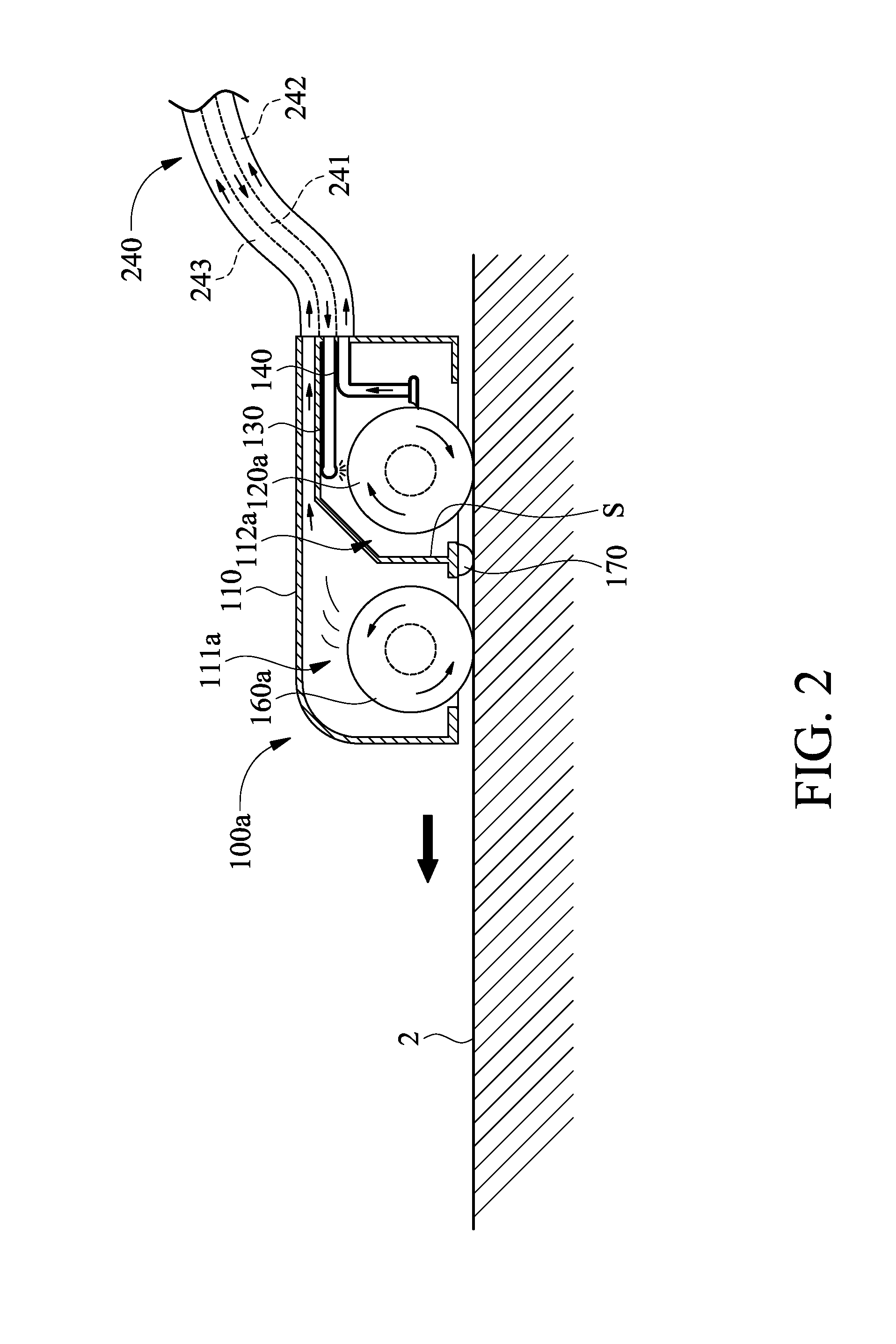

[0031]Referring to FIG. 1 through FIG. 4, there are shown schematic views of an electric sweeping washing device 1000 according to the present invention. The electric sweeping washing device 1000 is for use in sweeping and washing a floor 2 (such as a floor and a rug.) The electric sweeping washing device 1000 comprises a sweeping washing brush 100a and a water collection system design 200.

[0032]The sweeping washing brush 100a comprises a body 110, a sweeping roller brush 160a, an auxiliary wheel 170, a water absorbing scrubbing roller brush 120a, a sprinkler head 130, and an water absorbing scraper 140.

[0033]The body 110 has a separating board S for demarcating and separating a sweeping washing brush front 111a from a sweeping washing brush rear 112a. Both the opening of the sweeping washing brush front 111a and the opening of the sweeping washing brush rear 112a face the floor 2.

[0034]The sweeping roller brush 160a is disposed inside the sweeping washing brush front 111a and drive...

second embodiment

[0061]Referring to FIG. 9 through FIG. 13, there are shown schematic views of an electric sweeping washing device 3000 according to the present invention. The electric sweeping washing device 3000 is for use in washing a window 1. The electric sweeping washing device 3000 comprises a washing brush 100 and a water collection system design 200.

[0062]The washing brush 100 comprises a body 110, a water absorbing scrubbing roller brush 120, and a sprinkler head 130.

[0063]The body 110 has a washing brush casing 111. The opening of the washing brush casing 111 faces the window 1, as shown in FIG. 13.

[0064]The water absorbing scrubbing roller brush 120 is disposed inside the washing brush casing 111 and driven by a washing brushed motor 121 to rotate.

[0065]The sprinkler head 130 is disposed inside the washing brush casing 111. The sprinkler head 130 faces the water absorbing scrubbing roller brush 120 and washes off tiny dust and dirty water otherwise adhered to the water absorbing scrubbin...

third embodiment

[0077]Referring to FIG. 9 through FIG. 13, there are shown schematic views of operation of the electric sweeping washing device according to the present invention, wherein the washing brush 100 and the window 1 are shown.

[0078]During the process of cleaning the window 1 with the water absorbing scrubbing roller brush 120, the clean water stored in the clean water chamber 220 is taken in by the spray motor 250, delivered by the spray tube 241, and sprinkled by the sprinkler head 130 onto the water absorbing scrubbing roller brush 120 to thereby remove dust or dirt from the water absorbing scrubbing roller brush 120.

[0079]The air intake motor 260 reduces the internal pressure of the dirty water chamber 230 to vacuum pressure, such that the water absorbing scraper 140 rakes dust-containing or dirt-containing dirty water on the water absorbing scrubbing roller brush 120 and delivers the dirty water to the water absorbing tube 242, and in consequence the dirty water is collected in the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com