Quarter turn torque anchor and catcher

a quarter-turn torque and catcher technology, applied in the direction of tubing catchers, fluid removal, drilling accessories, etc., can solve the problems of affecting the use effect, the cost of manufacturing the threaded parts, and the prone to breakage of the stop pin during us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

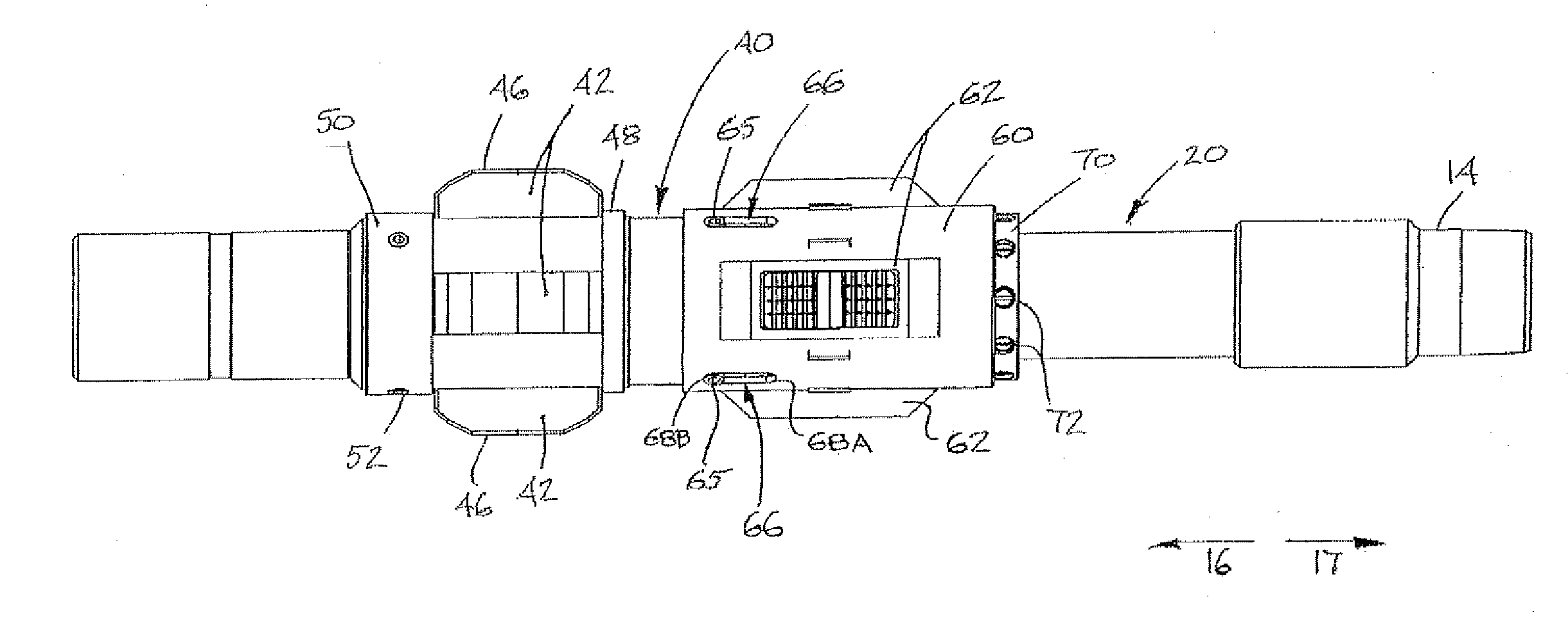

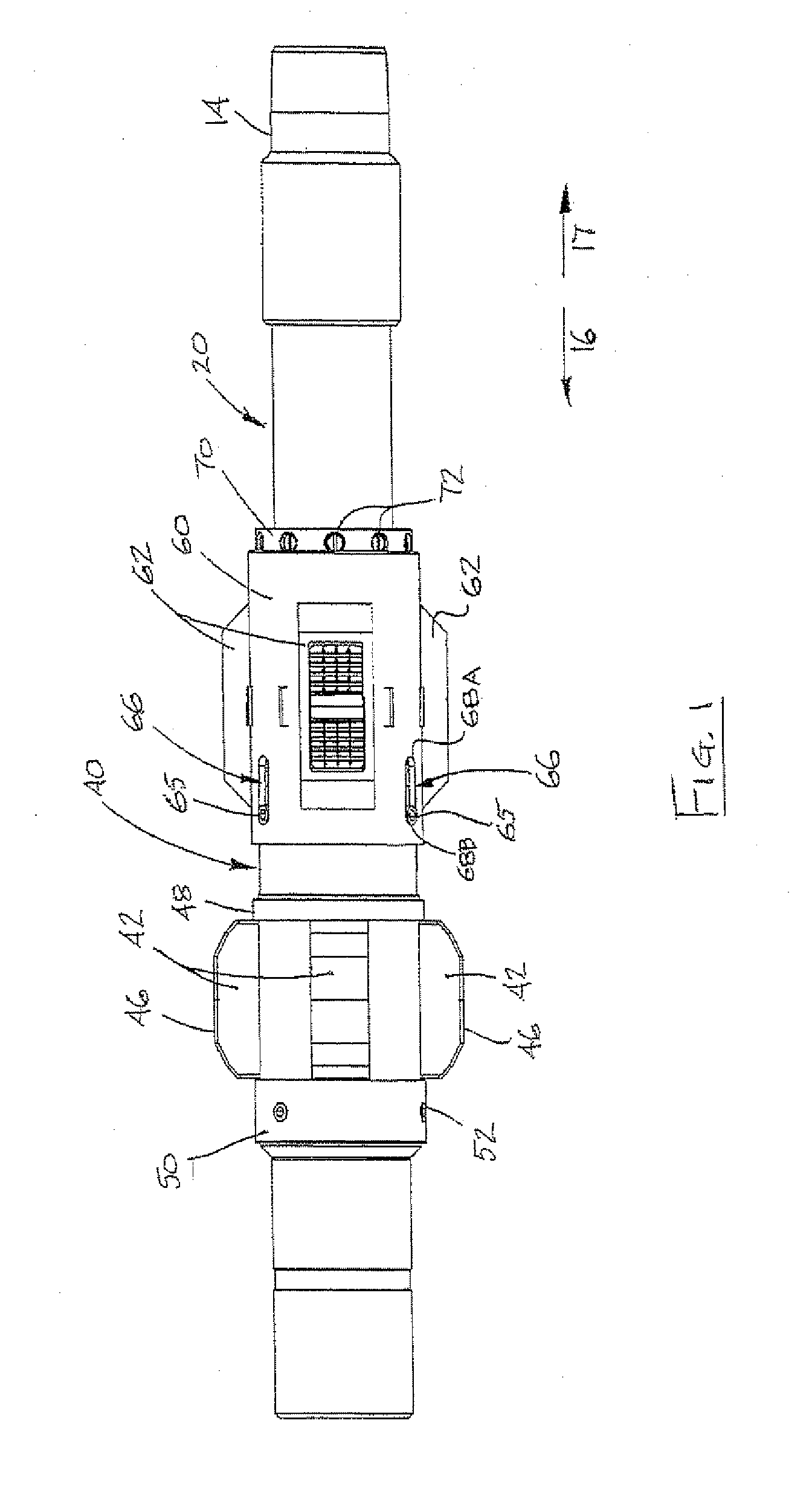

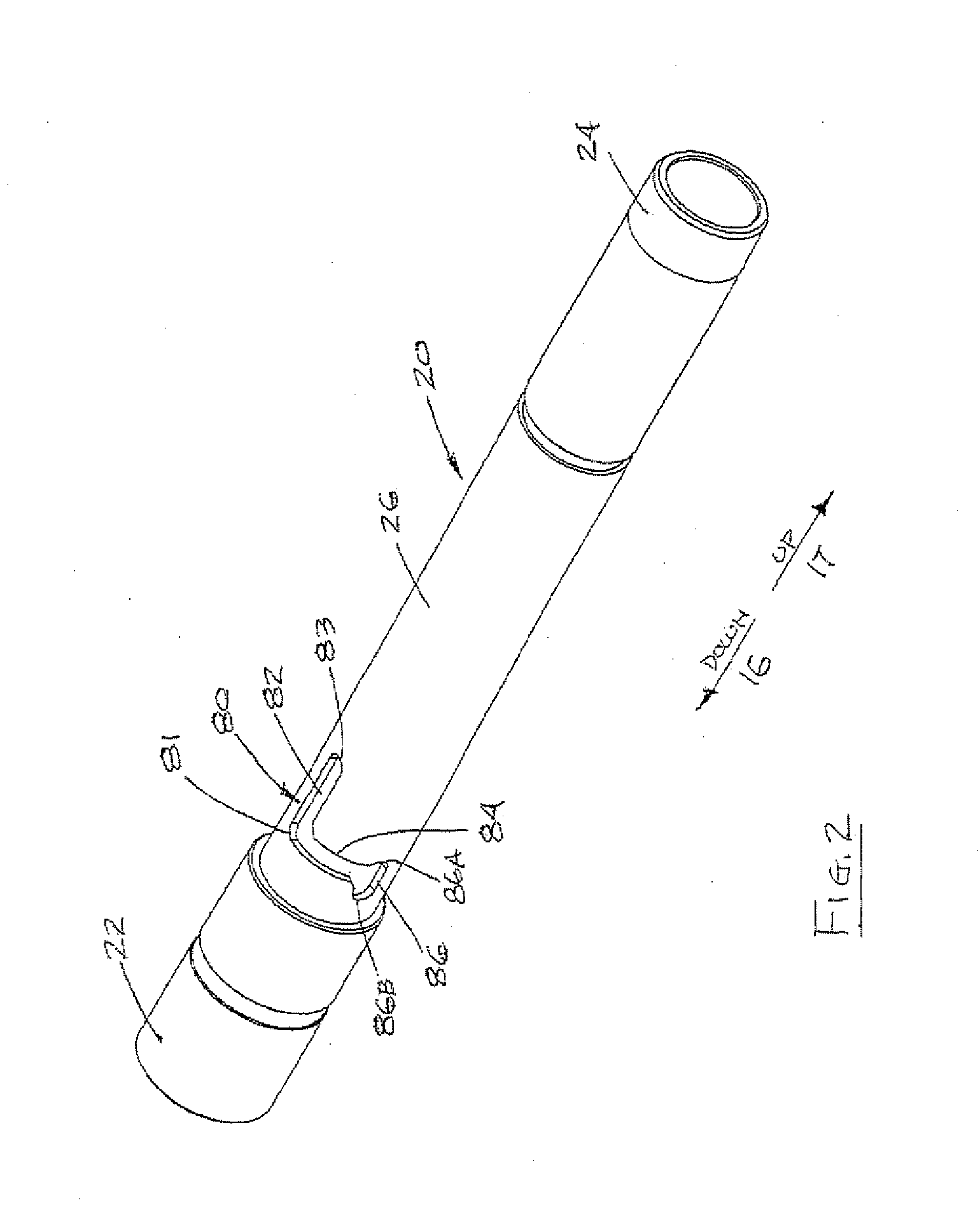

[0055]Referring first to FIGS. 1 to 5, a preferred embodiment of a tubing anchor, generally indicated by reference numeral 10, is shown inserted within a well conduit 12, such as a wellbore casing. The tubing anchor is shown in an unset, or “run-in”, orientation in which it can be run inside the well conduit on a tubing string, along with other well equipment 14, such as a safety sub, attached above and below. In particular, the well equipment is attached to a cylindrical mandrel 20 having attachment means, such as an inner threaded lower end 22 and an outer threaded upper end 24. In this embodiment, the tubing anchor is run down the well conduit on the tubing string in the direction indicated by arrow 16. It is noted, however, that terms such as “up”, “down”, “forward”, “backward” and the like used to identify certain features of the tubing anchor when placed in a well conduit is not intended to limit the tubing anchor's use or orientation. Further, when describing the invention, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com