However, said devices are not widely applied to bottles, mainly to bottle lids for mineral water, soft drinks or isotonic drinks mainly due to the size of the lid and particularly to the surface of said lid.

This is because the distance between both inlet and outlet is limited by the surface of the lid, making it necessary to arrange the inlet and outlet close to one another.

The fact that the closure device is formed by different bodies or elements coupled to one another involves a manufacturing cost increase because the assembly and coupling of different components to the body of the lid must be added to the independent manufacture of the different components, sometimes with materials having specific characteristics such as latex or silicone.

This means that these closure devices are intended to be reused due to their high cost compared with lids typically used in small volume PET bottles containing liquid for personal consumption and mainly used by children, the elderly and athletes.

Obviously this accumulation of dirt / moisture is little hygienic, and can generate health problems to the person using the device, in addition to not being nice aesthetically.

If the consumer sucks, problems derived from said suction, such as the need to stop sucking to take a breath and be able to continue drinking and deformation of the receptacle due to collapse, being creased and / or crushed indiscriminately while sucking, causing a change in the shape of the receptacle, especially when it is made of PET, making it difficult to hold, will occur.

These problems are worsened if the consumers are young children, convalescents or the elderly who need a break to take a breath, running the risk of drinking a lot of liquid since they cannot control the suction exerted with the subsequent risk of choking.

A suction cup effect that is annoying for the consumer is created in lids of the state of the art when drinking stops.

However there is no knowledge of any lid incorporating said device and having a hole for the entry of air into the receptacle equipped with a valve.

A problem common to all known lids of the state of the art and with the characteristics of those previously described is that they do not guarantee the asepsis of the liquid included in the receptacle, since they do not have effective closure means to prevent the entry of air through the two holes, for liquid and air, with the consequent risk of infection of the content.

This problem of infection can occur in different conditions:During the practice of sport in adverse situations, more specifically when the athlete circulates by dirty areas such as e.g. muddy areas or swampy areas that can release unwanted items that are deposited on the lids of the receptacles,During the use of the cap with dirty hands, orDuring storage in the refrigerator, after having used the lid to cool the remaining content, since it prevents outside air from entering the receptacle, since lowering the temperature causes a depression by cooling inside the receptacle and air can enter by the air inlet through the valve if the hole is not tightly closed.

The former problem is usually avoided by incorporating a top or cover to the lid, which can be integral or not with the same, however said top or cover, which may be useful in certain circumstances, is quite useless in the receptacles used by athletes.

Likewise, another problem in the lids of small dimensions with two holes, one for liquid outlet and another one for air inlet, is that the user, when drinking through the liquid outlet can plug with their mouth the air inlet, what would prevent the correct operation of the lid since it prevents the entry of air into the receptacle, leading to the use of the lid as a lid with a single hole.

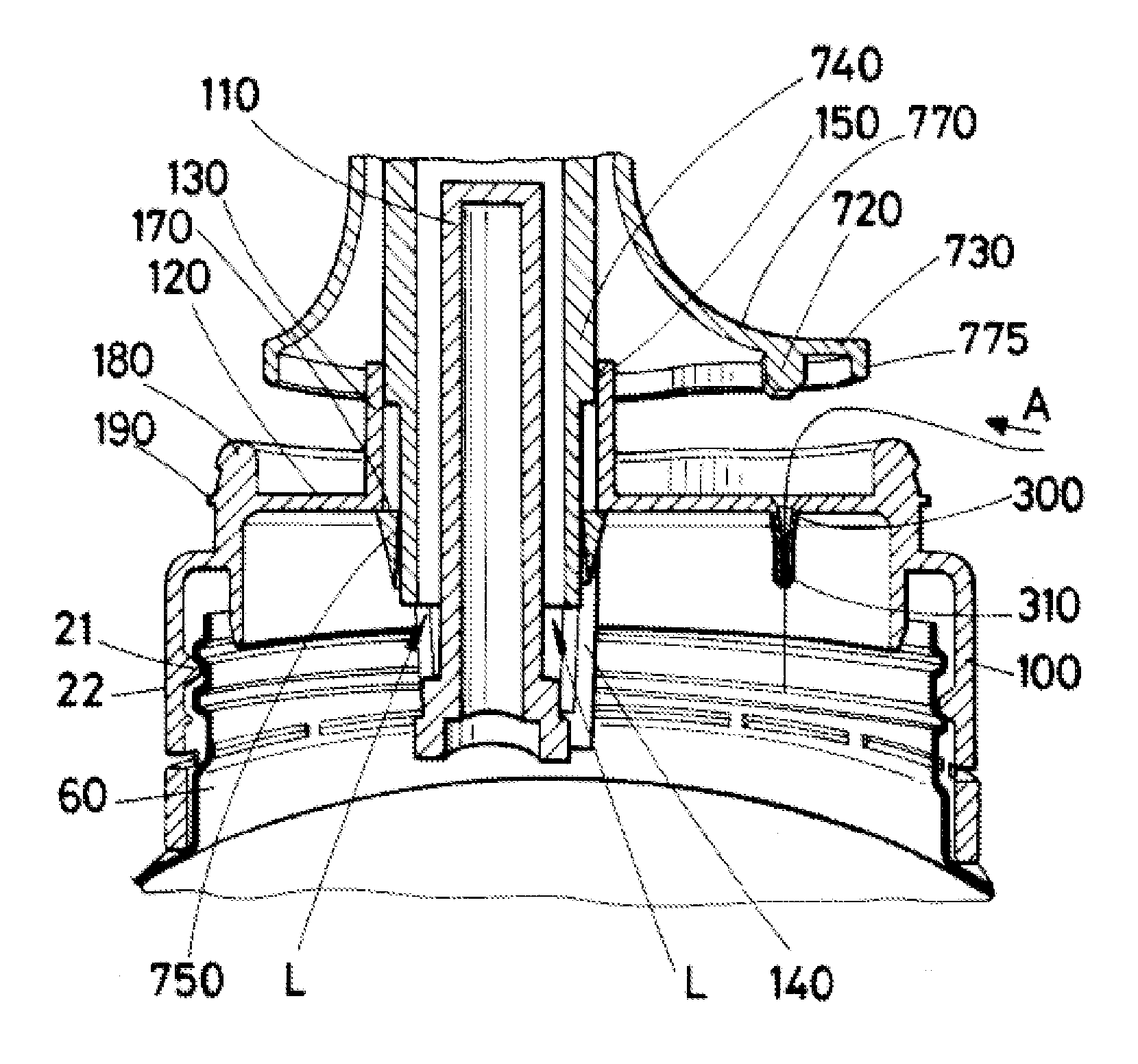

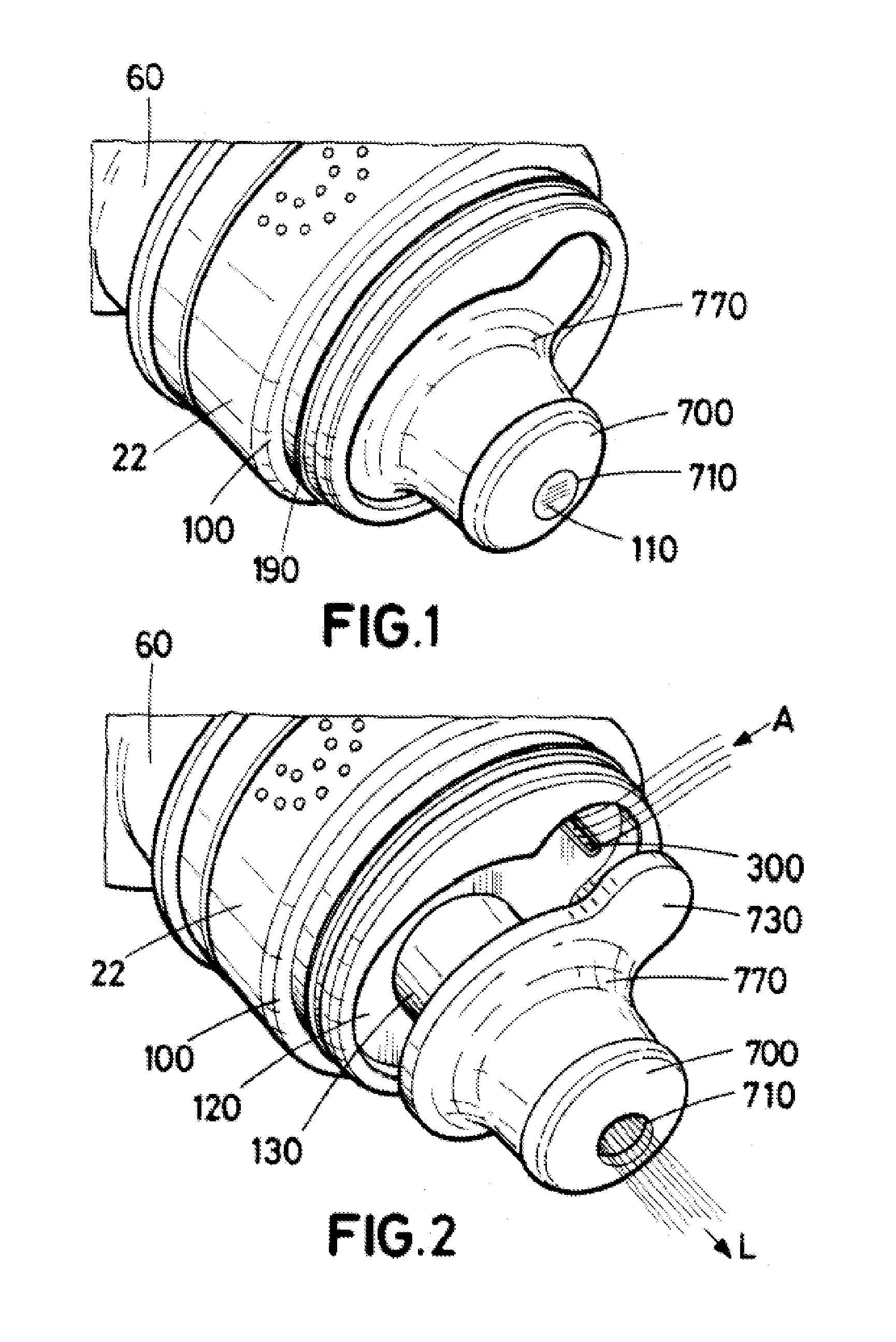

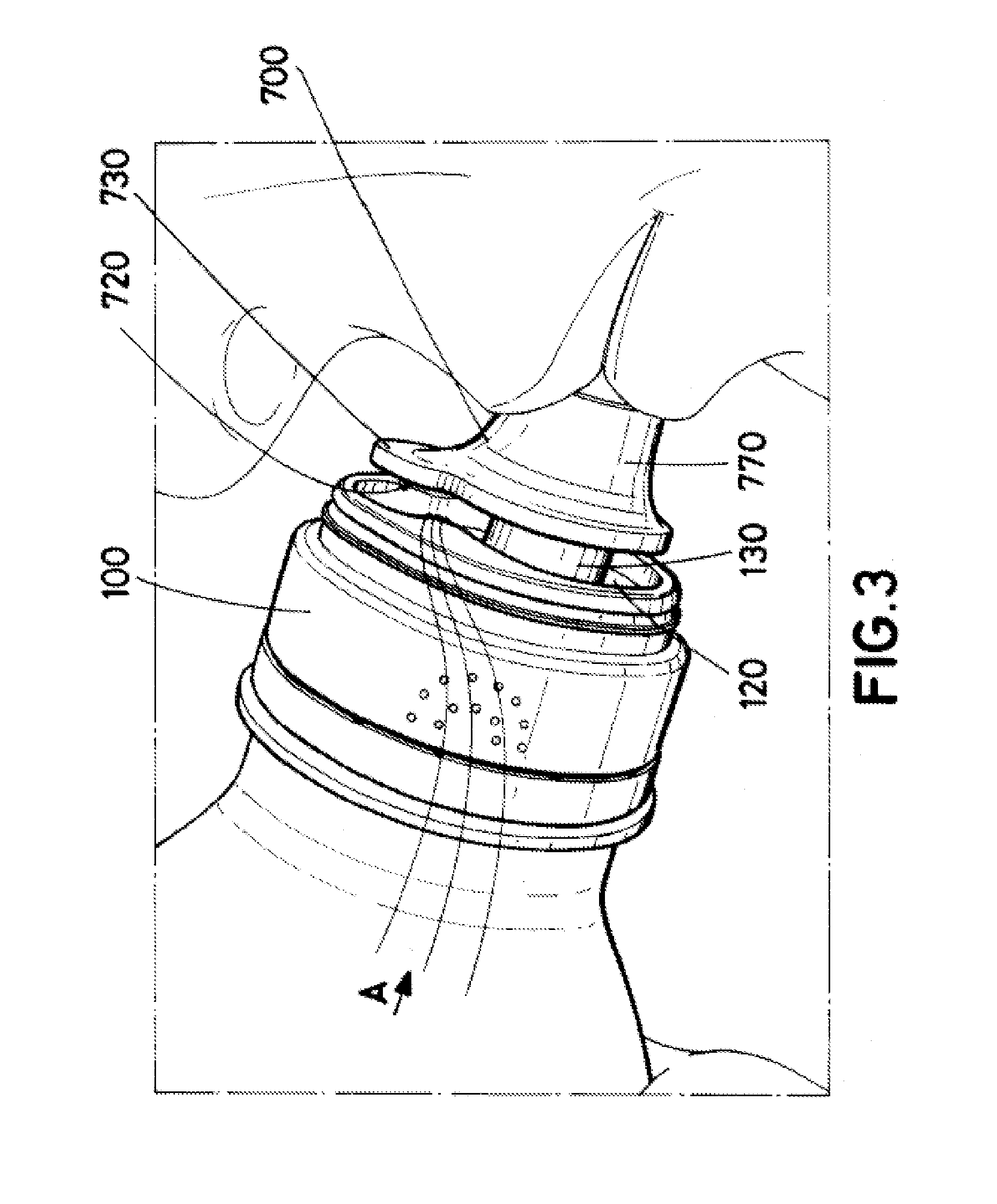

Login to View More

Login to View More  Login to View More

Login to View More