Insert for foiled food tubs and the like

a technology for inserts and food tubs, applied in the field of packaging inserts and blanks, can solve the problems of high financial burden on the responsible party, insufficient compartmentalization of articles packed with these packing supplies, and high cost of replacing and/or repairing damaged articles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013]While this invention is susceptible to embodiment in many different forms, there is shown in the drawings and will herein be described in detail preferred embodiments of the invention. The present disclosure and preferred embodiments should be considered an exemplification of the principles of the invention and are not intended to limit the broad aspect of the invention.

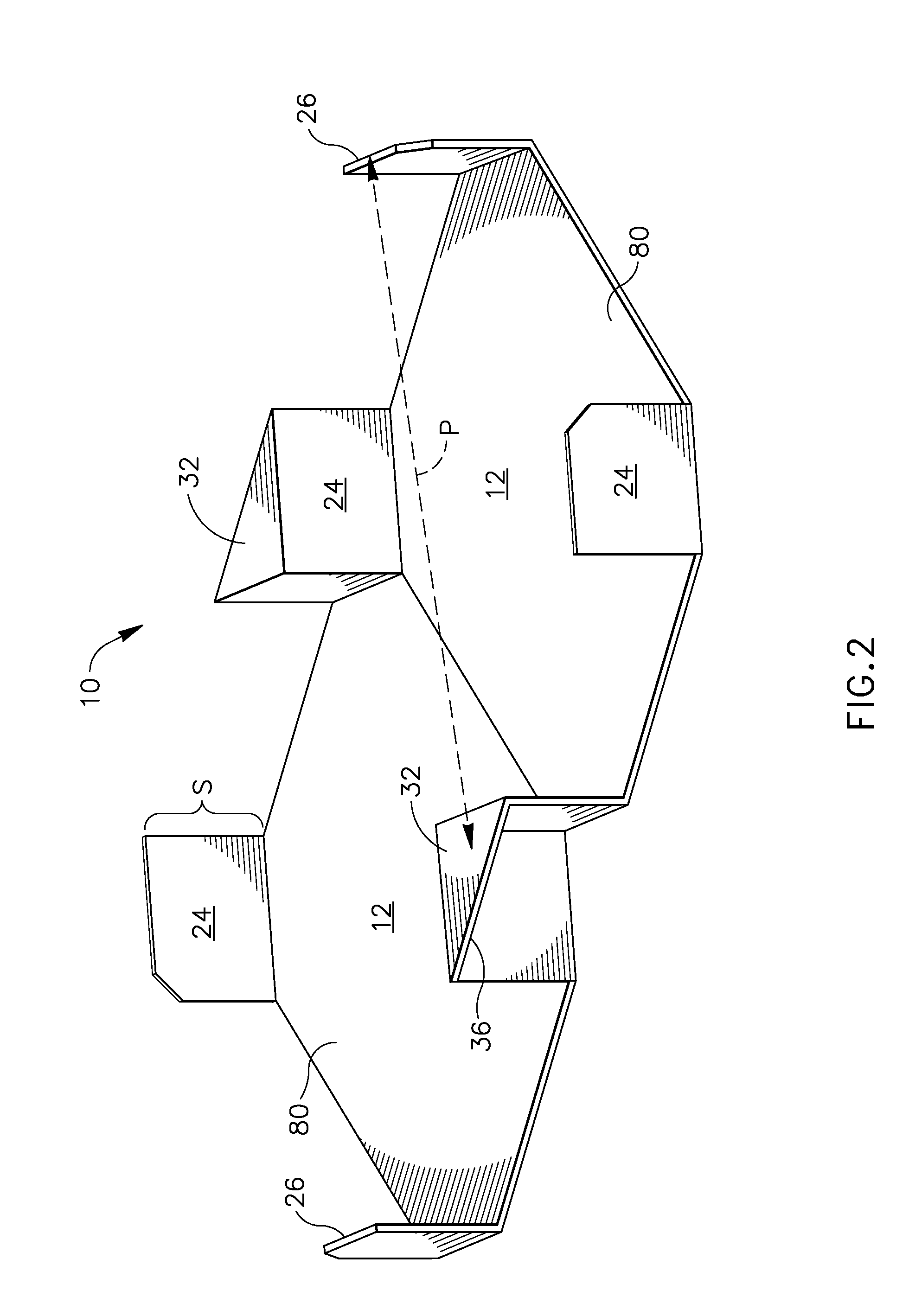

[0014]The insert 10 is formed from a single, unitary blank B. The blank B has a plurality of substantially rectangular bases 12. The number of bases 12 in a blank B corresponds to the number of compartments 80 the insert 10 will have when the blank B is folded into position, as is best shown in FIGS. 2 and 3 and discussed below. In a preferred embodiment of the invention shown in FIG. 1, there are two bases 14 in a single column per blank B. In another embodiment of the invention (not illustrated), there are two bases 14 in two columns per blank, namely the pattern of blank B is doubled. Similarly, in yet anoth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com