Custom Made Cuff LInks and Method for Making the Same

a cuff link and custom technology, applied in the field of custom made cuff links, can solve the problems of few choices, if any, in regard to cuff links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

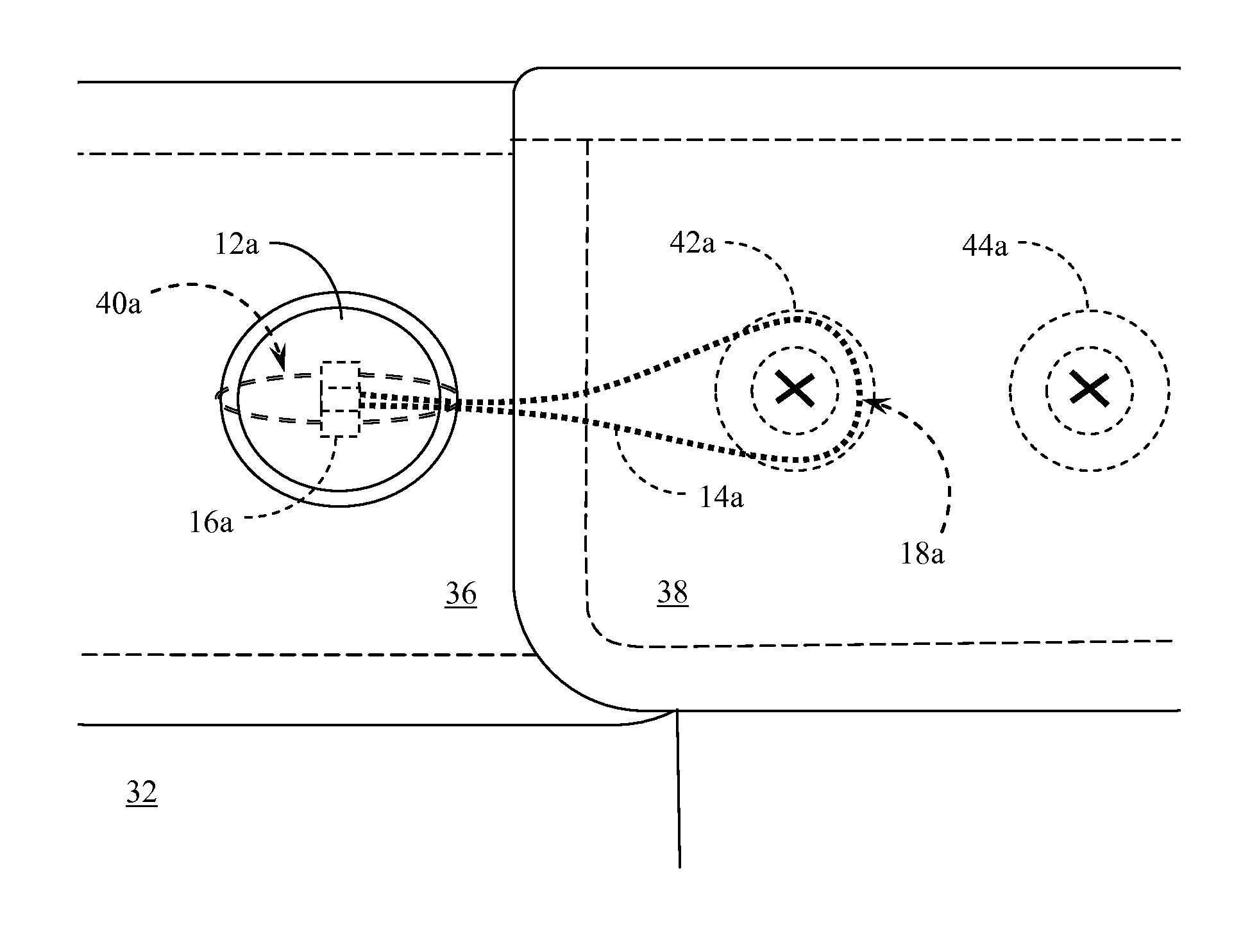

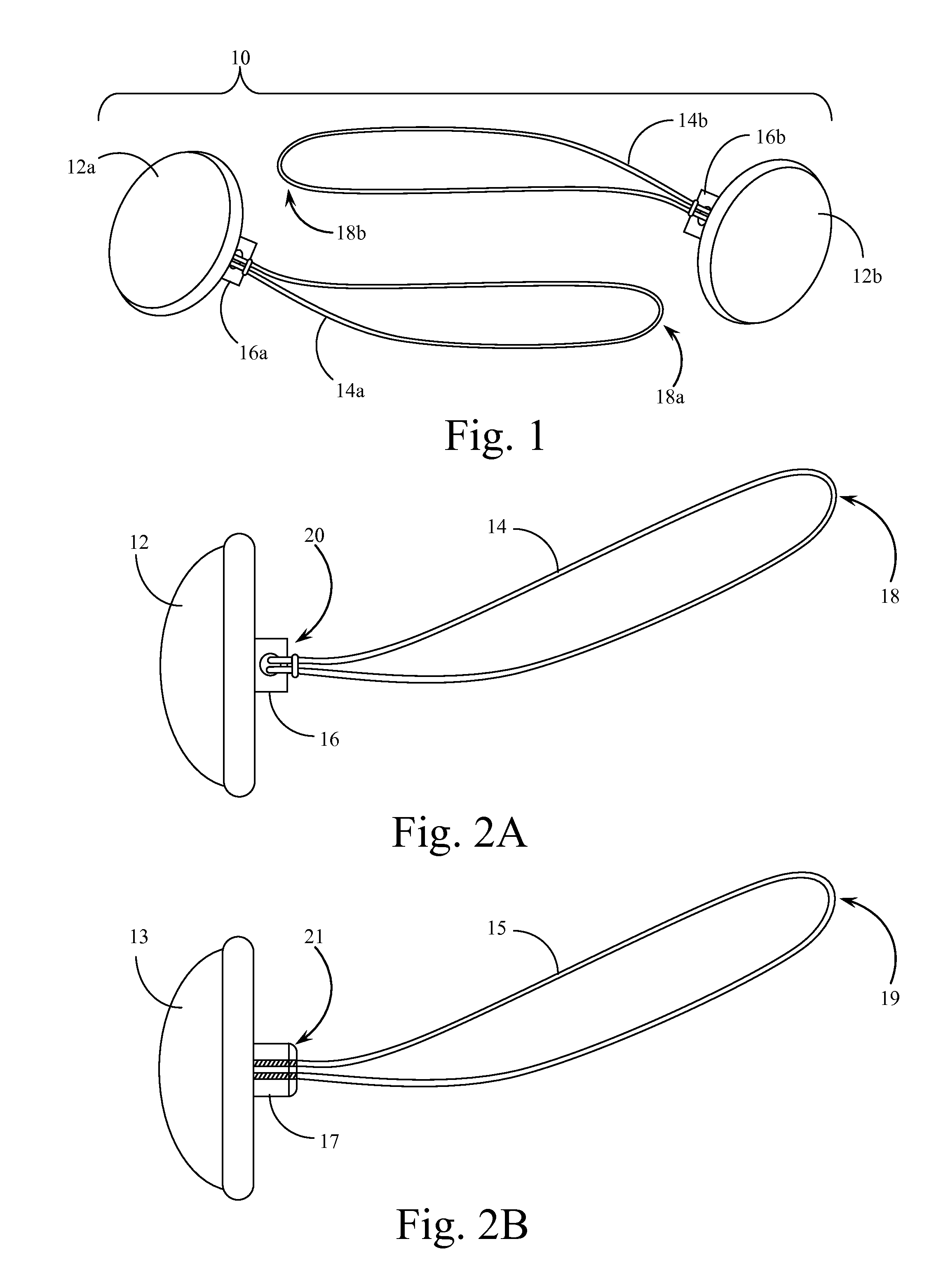

[0018]Reference is made first to FIG. 1 which is a perspective view of the custom made cuff links of the present invention showing a completed pair of cuff links. Custom made cuff link pair 10 is shown to be configured from button like components 12a and 12b which may be any of a number of different buttons or other such objects selected by the maker of the cuff link pair. The present invention is intended to accommodate a wide variety of buttons and button like objects and to most easily accommodate buttons of the type that have an aperture through which the monofilament line component of the present invention may extend. In FIG. 1 monofilament line components 14a and 14b are shown to each extend from button attachment posts 16a and 16b. The monofilament line components 14a and 14b from monofilament line loop ends 18a and 18b which, in the preferred embodiment, may be a single closed loop of clear polymer fiber attached back on itself to form a loop. Alternately, components 14a and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| cut length | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com