Liquid pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

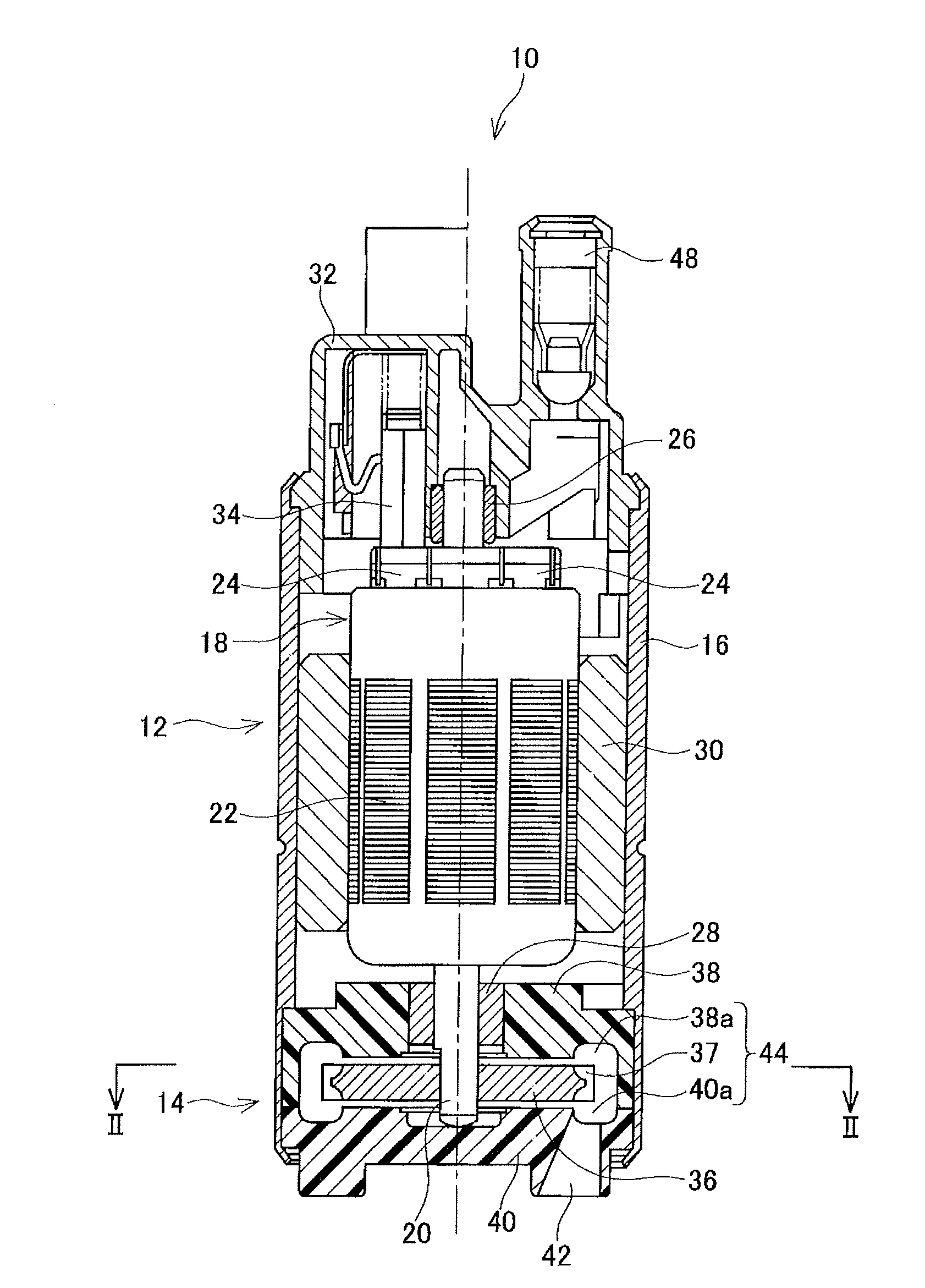

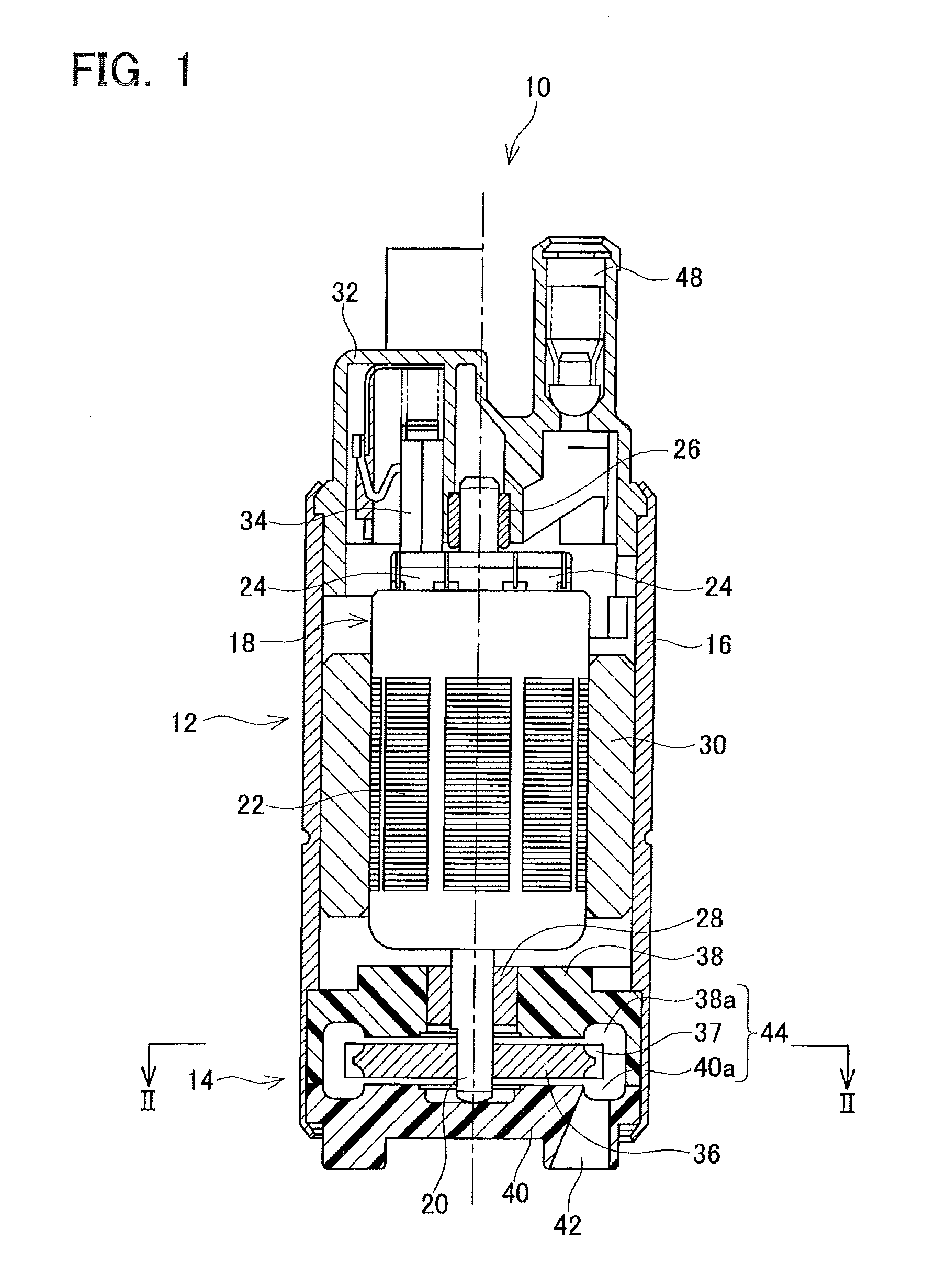

[0023]An embodiment of the present teaching will be described below with reference to the drawings. A fuel pump of the present embodiment is a fuel pump for an automobile, however, it should be understood that the teaching disclosed herein may suitably be applied to other purposes. The fuel pump is used within a fuel tank in order to supply fuel to an engine of an automobile. As shown in FIG. 1, the fuel pump 10 comprises a motor unit 12 and a pump unit 14. The motor unit 12 and the pump unit 14 are contained within a housing 16. The motor unit 12 comprises a rotator 18. The rotator 18 comprises a shaft 20, a layered iron core 22, a coil (not shown) and a commutator 24. The layered iron core 22 is fixed on the shaft 20. The coil is coiled around the layered iron core 22. The commutator 24 is connected with an end of the coil. The shaft 20 is supported by bearings 26, 28 in a manner that a rotation relative to the housing 16 is allowed. A permanent magnet 30 that surrounds the rotato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com