Thermal Containment System Providing Temperature Maintaining Shipping Package with Segmented Flexible PCM Panels

a technology of temperature maintaining and containment system, which is applied in the direction of packaging goods type, domestic cooling apparatus, lighting and heating apparatus, etc., can solve the problems of limiting the international shipments of biological materials, and affecting the safety of consumers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

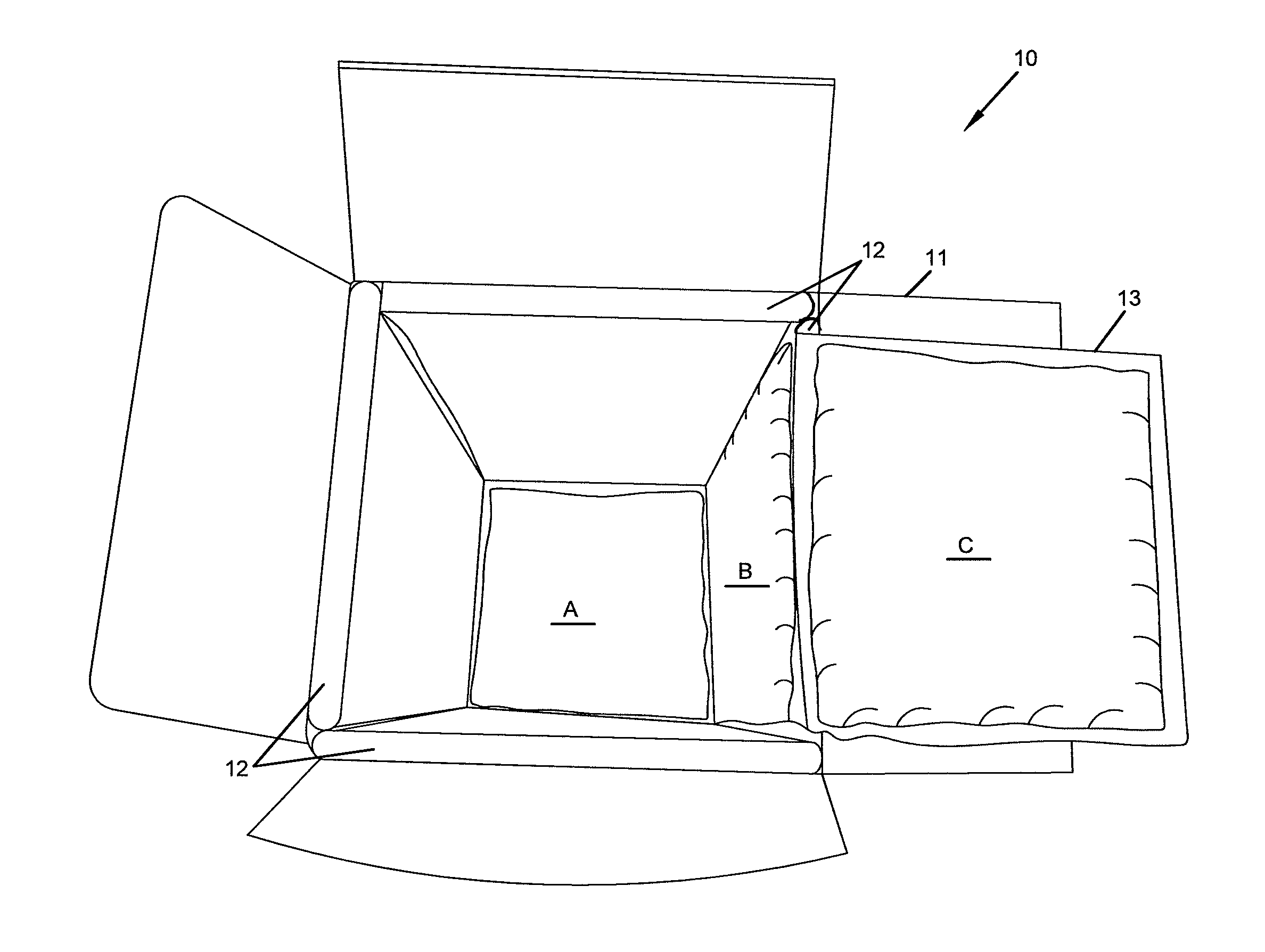

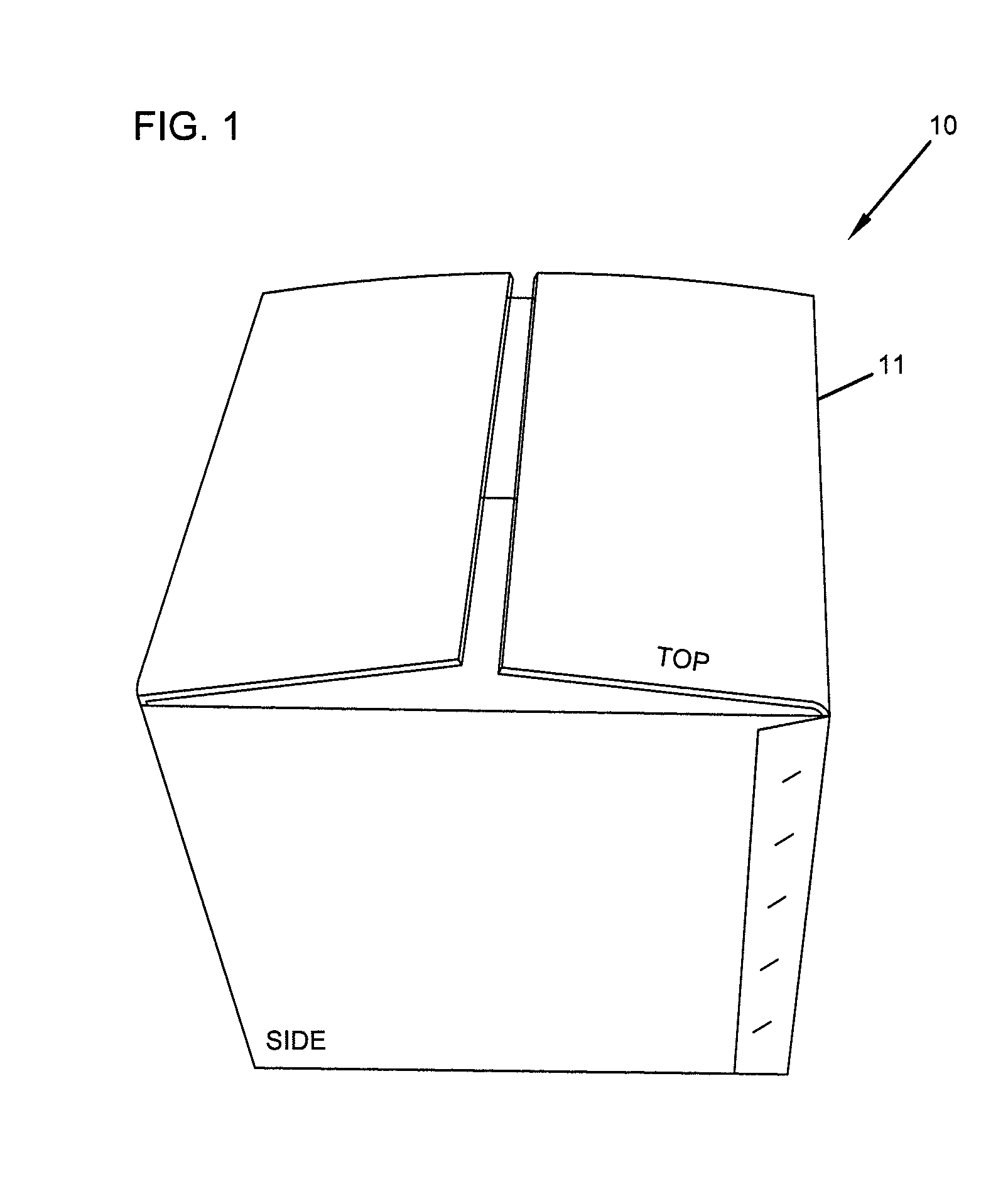

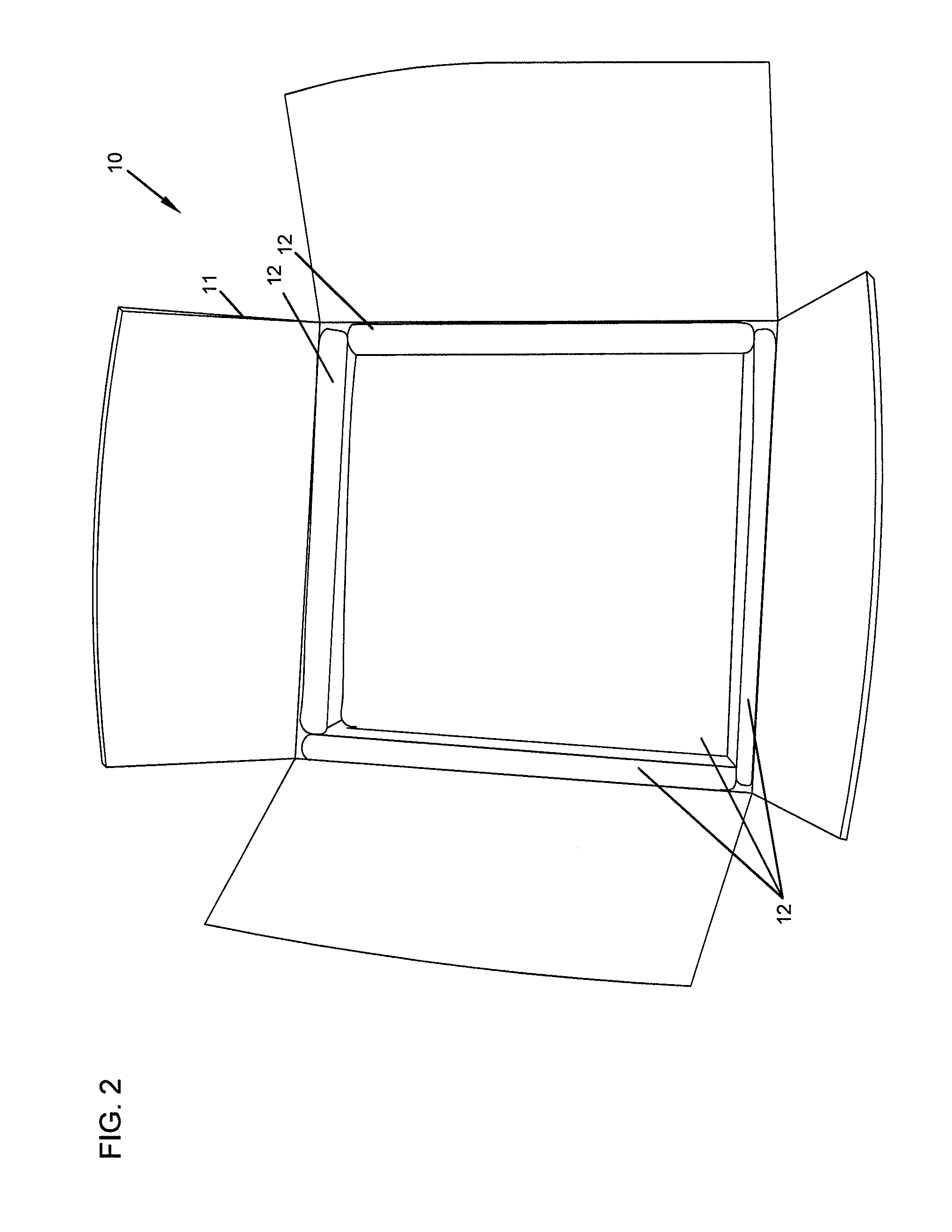

[0034]The packaging system of the present invention was developed for shipments of goods which must be kept within narrow temperature ranges over a period of days under uncontrolled ambient temperature conditions. Such goods include biological products, blood products, vaccines, pharmaceuticals, chocolate products, latex paints, etc. The system described herein can be configured to maintain controlled product temperatures under both high and low ambient temperature conditions.

[0035]This system uses phase change materials for tight temperature control and minimum shipping weight and volume. These phase change materials are reusable, and can save significantly on shipping costs. Various numbers of layers of phase change material may be used based upon time requirements, ambient temperature requirements, thermal insulation factor of the outer container, and the degree of temperature control required for the product. Descriptions of various phase change materials, parameters and enginee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com