Shipping container, system and packing method, along with reusable packing accessory for use therewith

a technology for shipping containers and accessories, applied in the field of containers, can solve the problems of increased packing costs, inefficient use of parcel carriers' space, and excessive padding of shipping items, and achieve the effect of reducing the risk of damage or loss of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

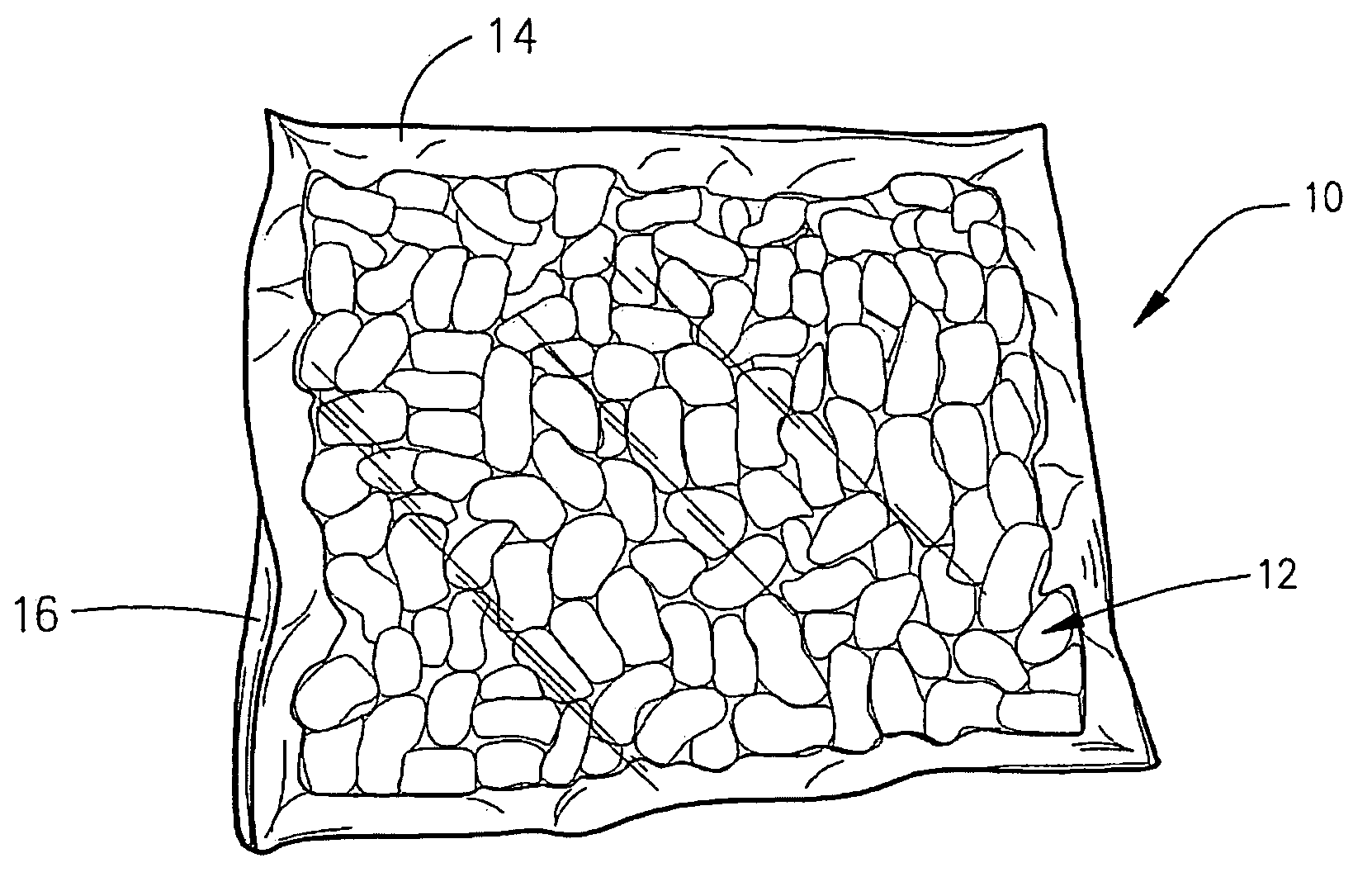

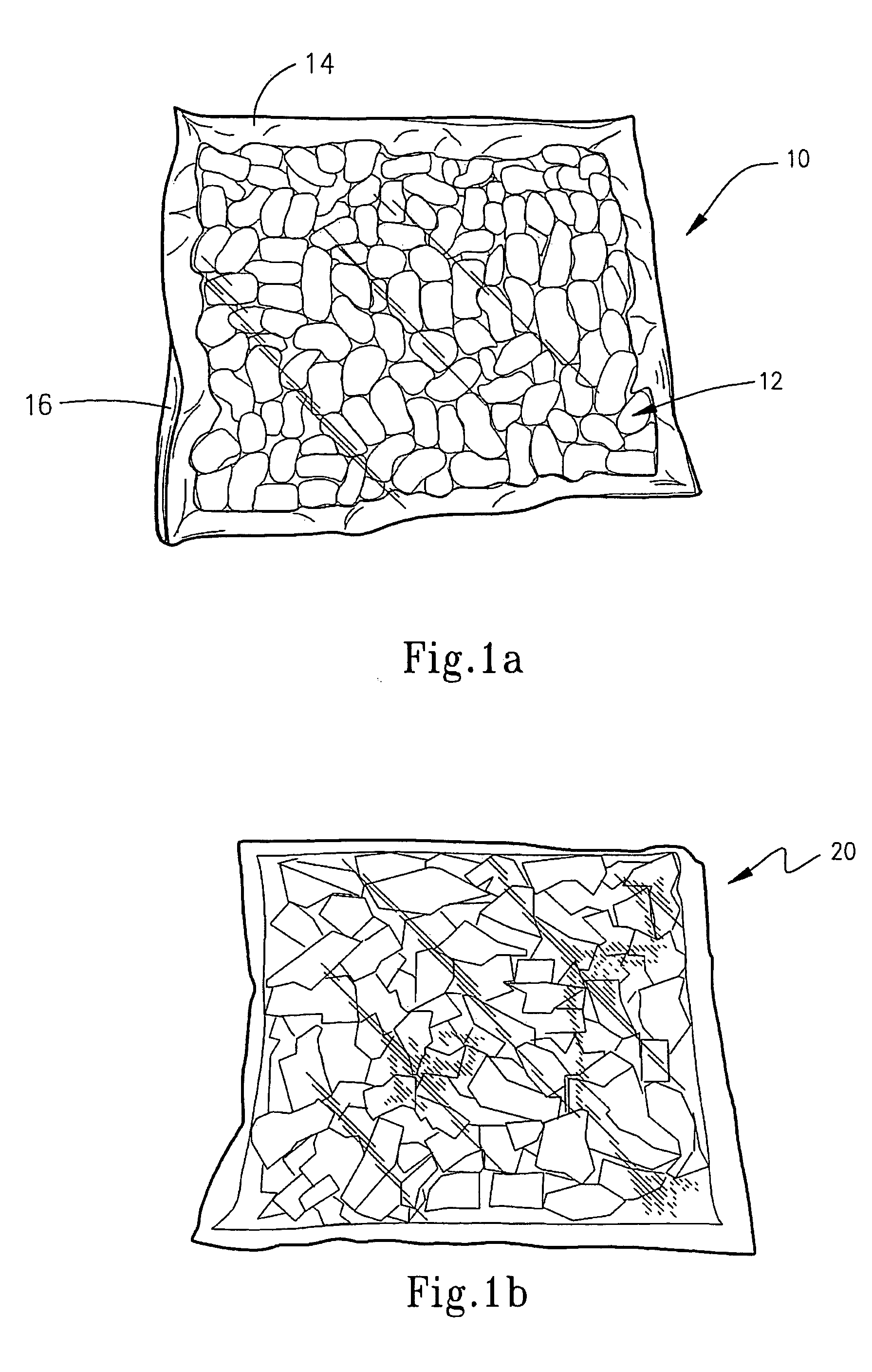

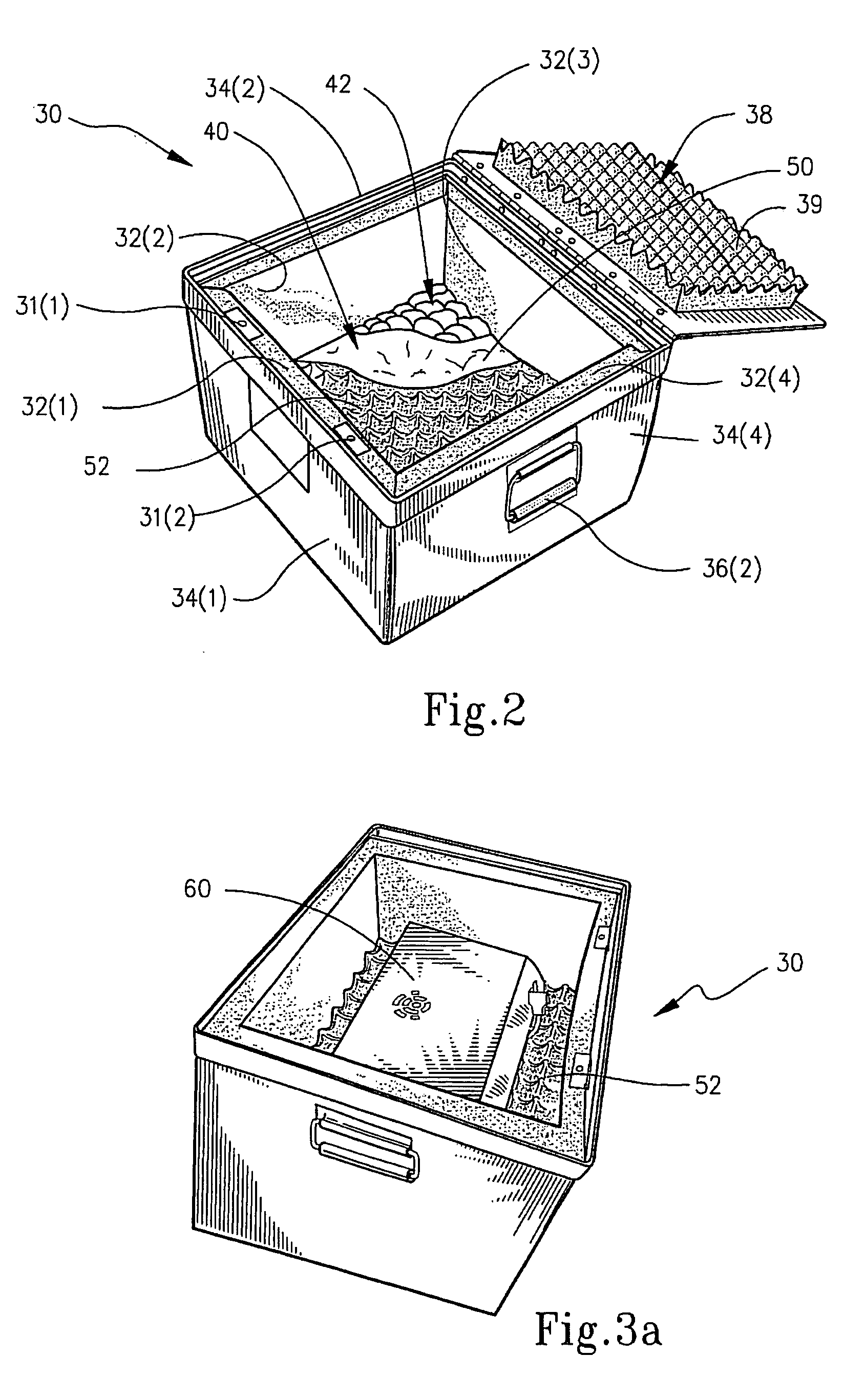

[0017]With initial reference, then, to FIGS. 1a and 1b, two exemplary embodiments of packing accessories are illustrated. A first exemplary embodiment of a packing accessory 10 is introduced in FIG. 1a and is form of a reusable cushioning bag or pillow. To this end, packing accessory 10 includes a sealed bag 12 which contains cushioning material in the form of a plurality of packing styrofoam “peanuts” as commonly available in the industry. Oftentimes, these peanuts are distributed loosely within a shipping container to surround the contents, and disposed of when the container is opened by the recipient. Because they are loosely dispersed throughout the container, typically a cardboard box, they often become lodged in crevices or spilled as the contents within the box shift or are removed by the recipient. This can be somewhat frustrating to clean up. By containing the styrofoam peanuts within a sealed bag as shown in FIG. 1a, these drawbacks are eliminated. At the same time, howeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com