Refill device for dispensing a cosmetic product

a refill device and cosmetic product technology, applied in the direction of containers, liquid bottling, packaging goods, etc., can solve the problem of limited product decanting or transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

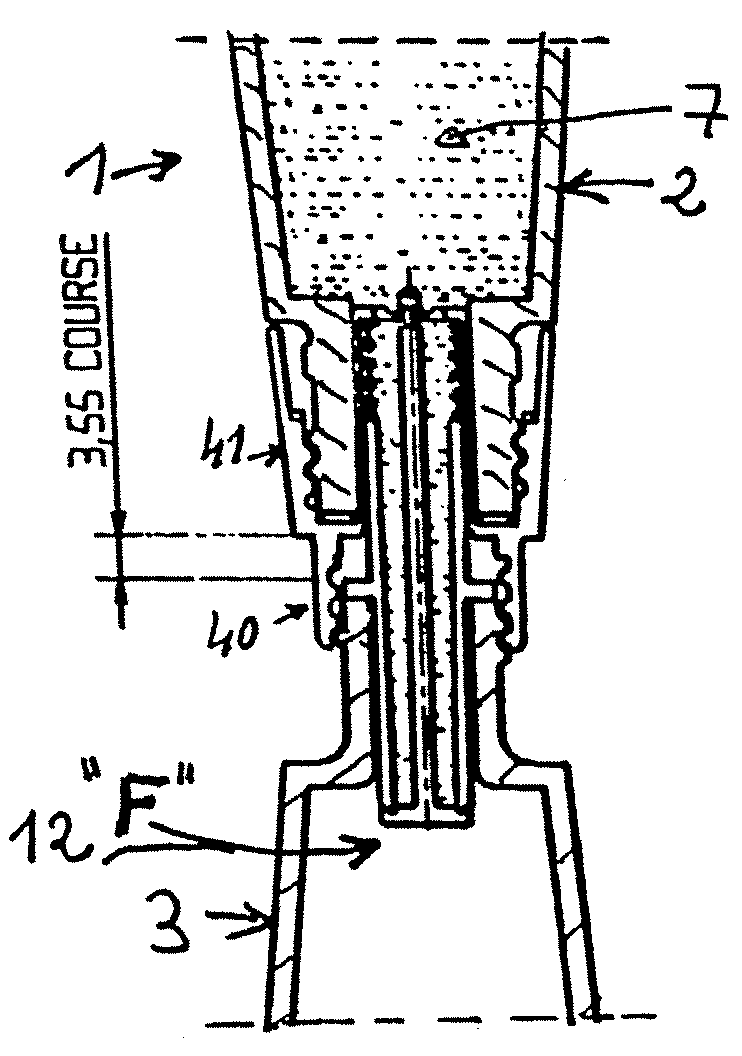

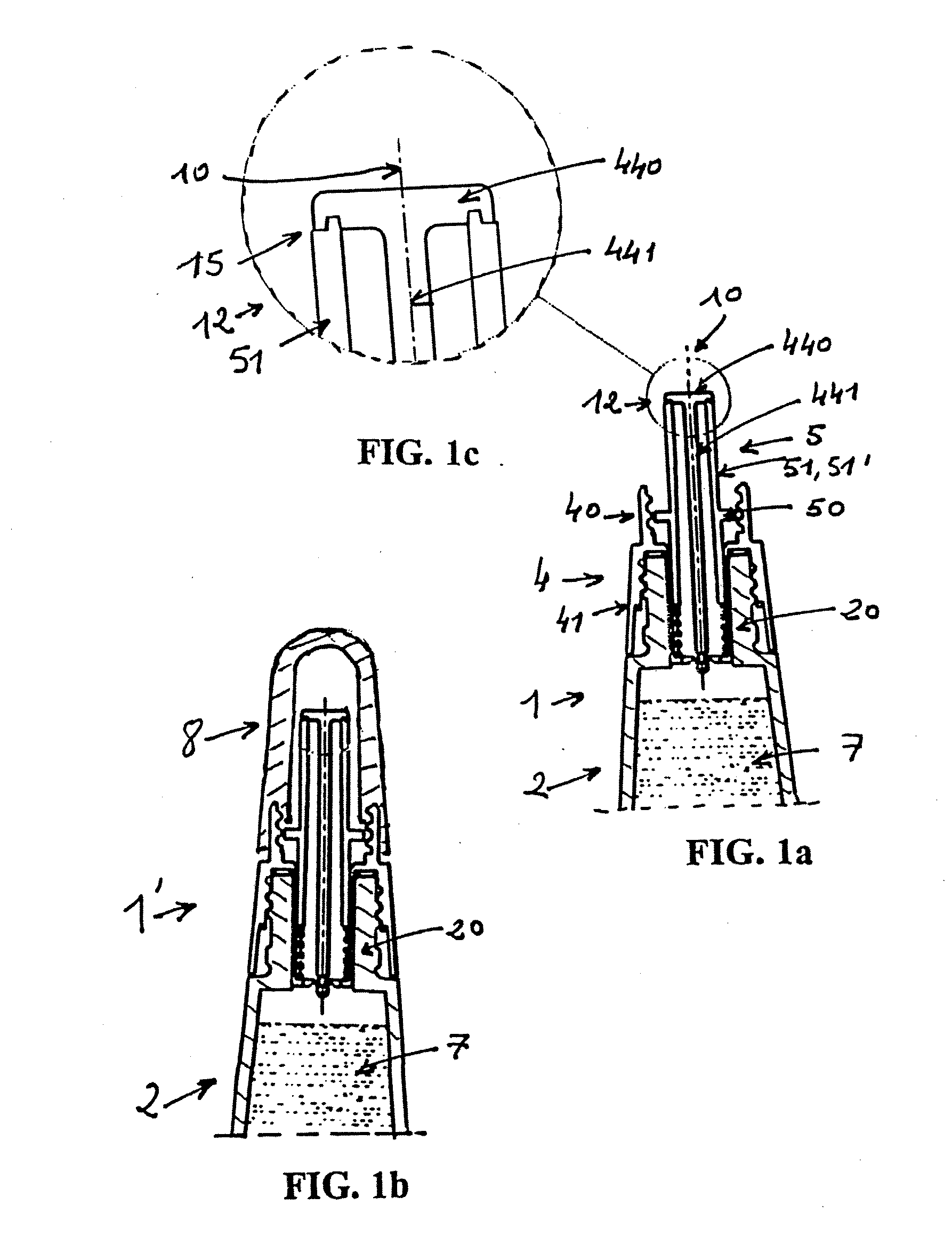

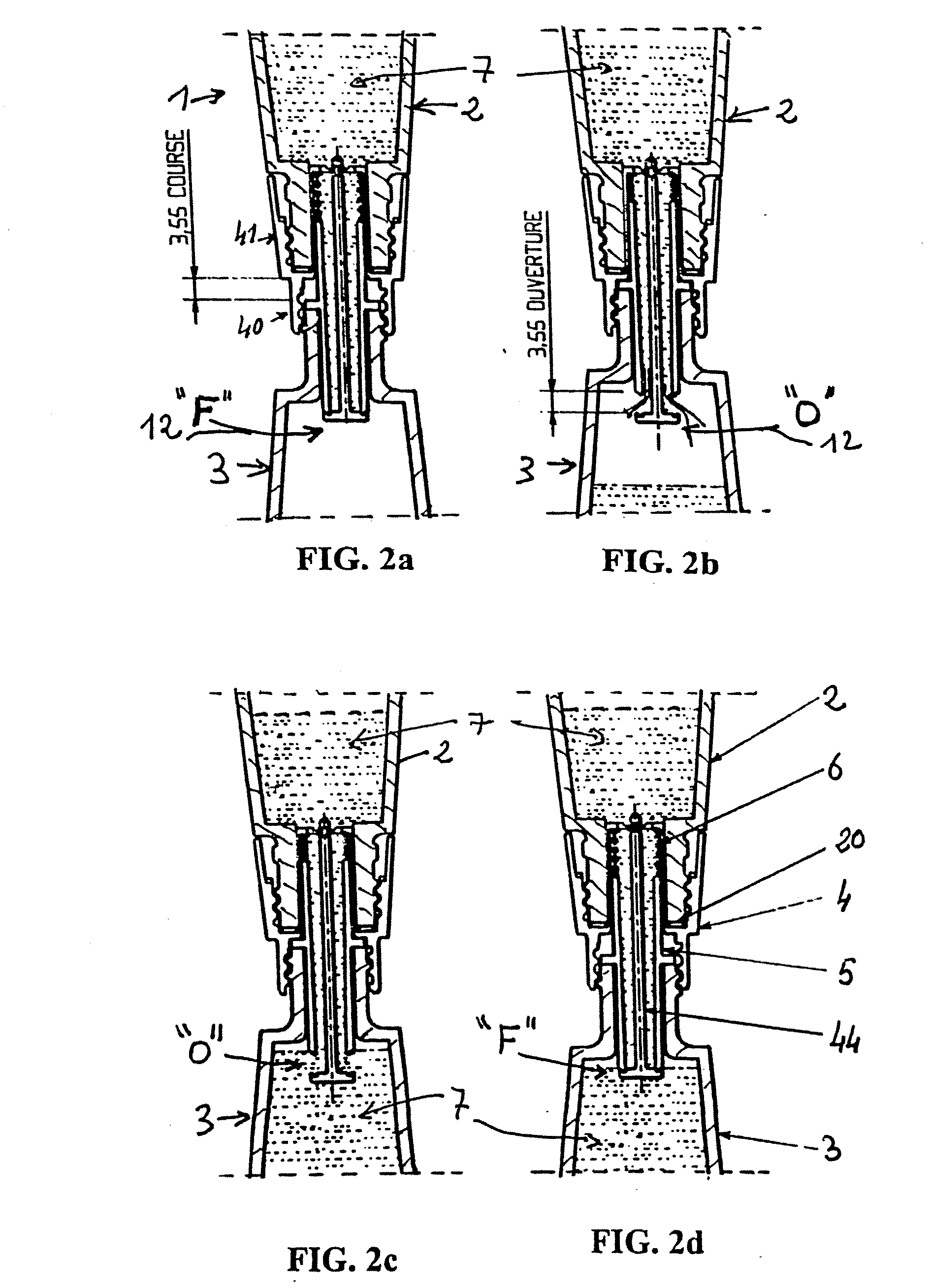

[0076]Device A was manufactured as illustrated in FIGS. 1a to 4a. To do this, thermoplastic material molding was used to manufacture:[0077]a) a connection component (4), which was an integral component, including: two internally threaded bearing plates (40) and (41), a median wall and an axial projection forming a tube portion and more specifically a lower tube portion fitted with a bottom having at least one orifice,[0078]b) a movable component, which was a unitary component, including a peripheral ring (50, 50′) and a central part forming a tube, and[0079]c) a central component (44), which was a unitary component, including the upper flap valve (440), the axial rod the lower end of which includes a means for snapping into the bottom.

[0080]A helical spring (6, 6′) was provided as well as the second container, fitted with a second threaded neck, and filled with liquid product intended to refill the first container.

[0081]These components were assembled by placing the spring in the lo...

example 2

[0083]Device B was manufactured as illustrated in FIGS. 5a and 5b. In this case, thermoplastic material molding was used to manufacture:[0084]a) a connection component as in device A,[0085]b) a movable component, which was a unitary component, including a peripheral ring (50, 50′) and a central part including a tube and an axial separation wall (52) forming the rod or axial wall and fitted with a lower snap-on end (517),[0086]c) a lower flap valve including a central snap-on orifice of diameter selected so that its lower edge (516) is able to be stopped against the lower end of the lower tube portion.

[0087]A helical spring (6, 6′) was provided as well as the second container (2). These components were assembled by snapping on the flap valve and the lower end (517) of the movable component (5).

example 3

[0088]Device C was manufactured as shown in FIGS. 6a and 6b. In this case, thermoplastic material molding was used to manufacture:[0089]a) a connection component (4), which was a unitary component, including a lower tube portion without a bottom (430),[0090]b) a movable component, which was a unitary component, including a peripheral ring (50, 50′) and a central part including a tube and an axial separation wall (52) forming the rod or axial wall integral with a lower flap valve (512). The lower flap valve includes a flexible outer edge (516′) able, by its shape, to be stopped against the lower end of the lower tube portion.

[0091]A helical spring (6, 6′) was provided as well as the second container (2). These components were assembled by forcibly snapping the movable component into the connection component (4), with the lower edge (516′) ensuring both the assembly of these two components and the tightness of the lower valve (12′).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com