Ballast extension-submersion truss stable platform

a stable platform and submerged technology, applied in waterborne vessels, special-purpose vessels, movement controllers, etc., can solve the problems of high cost, challenge, and current deep-water floating platform designs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Current technology for oil and gas production requires flooding a spar in deep waters with subsequent lifting and installation of topside structures over the up-righted spar. The process is expensive as spars require substantial steel, and transporting components to drill site for assembly and lifting tremendous weight onto a floating spar add to the costs and technical challenges. The BEST Stable platform could be constructed with less steel, fabricated completely in shallow water at or near a dock or yard, and towed as a finished platform to a location for drilling and production.

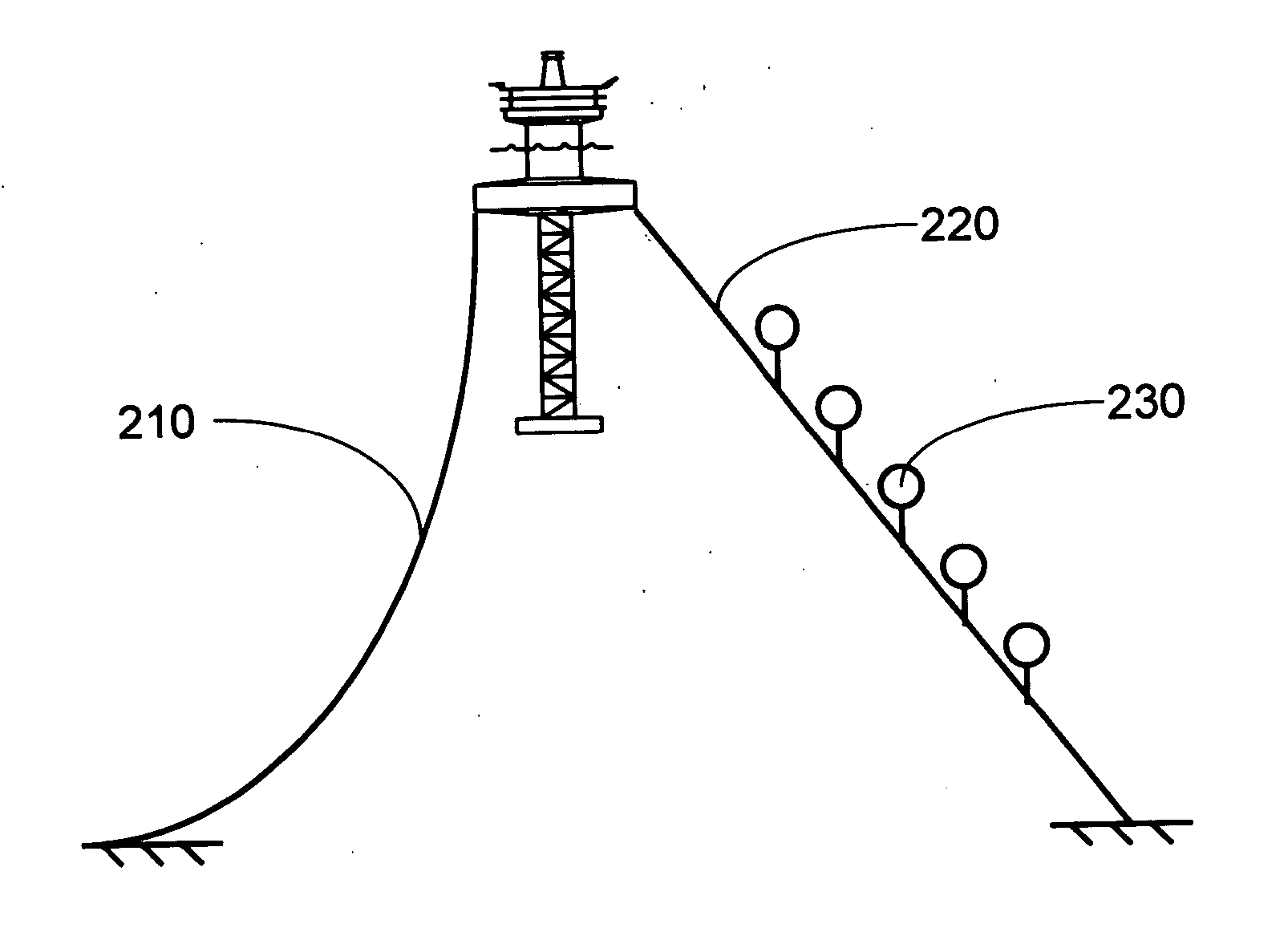

[0010]FIG. 1 shows a BEST Stable Platform 10 which includes a reduced water-plane area section floating at waterline 20. The figure shows platform configuration as deployed over a drill site. Float 30 provides buoyancy to support the entire platform, and in comparison to spars, a horizontally extending float 30 can enclose a larger volume with less steel and can be fabricated at lower cost. Furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com