Electropneumatic paintball gun, method of making and operating, and retrofit kit assembly

a paintball gun and electropneumatic technology, applied in the field of pneumatic marker or paint ball guns, can solve the problems of uncertain engagement and release of mechanical hammer and sear, and achieve the effect of reducing or eliminating at least on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

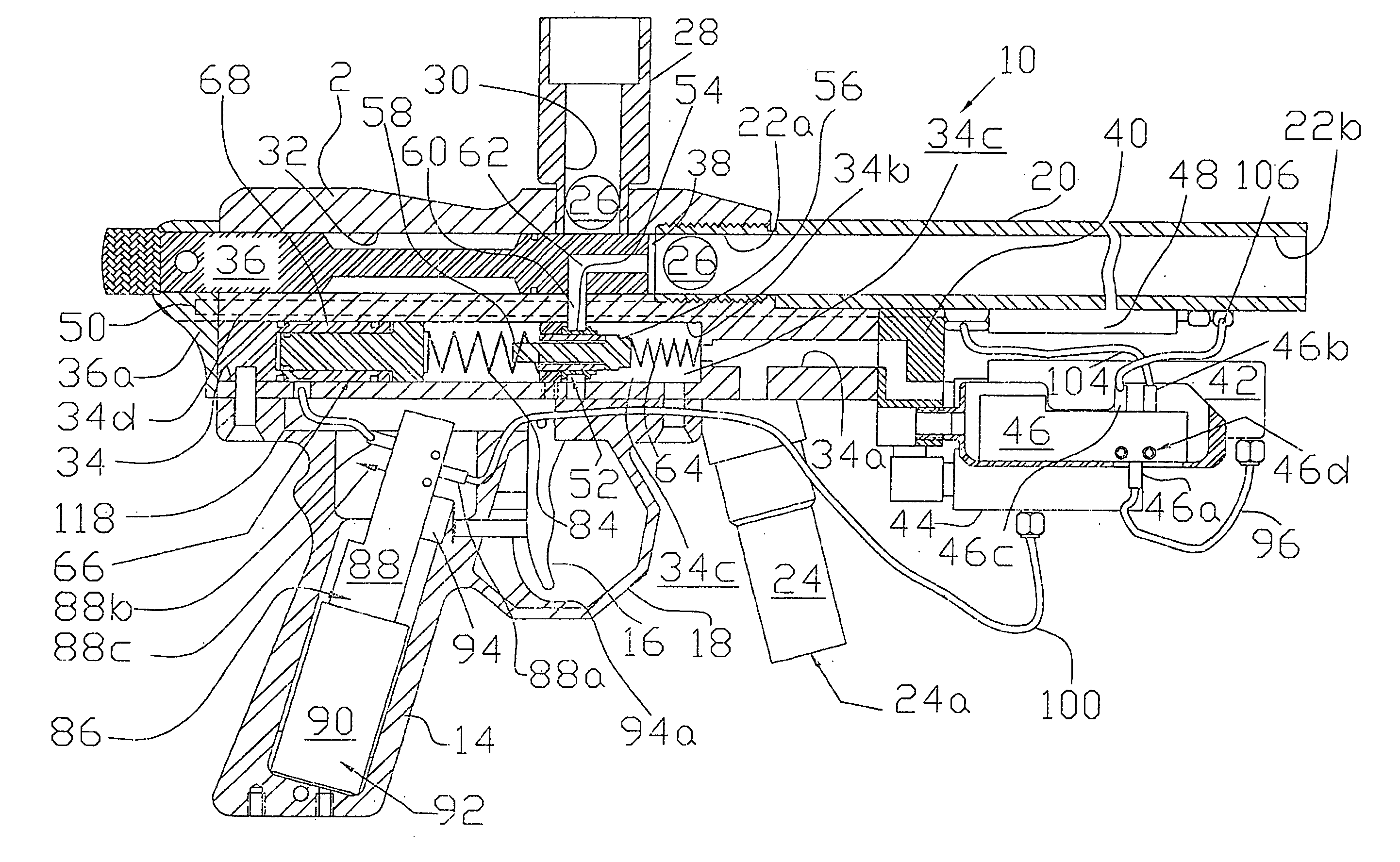

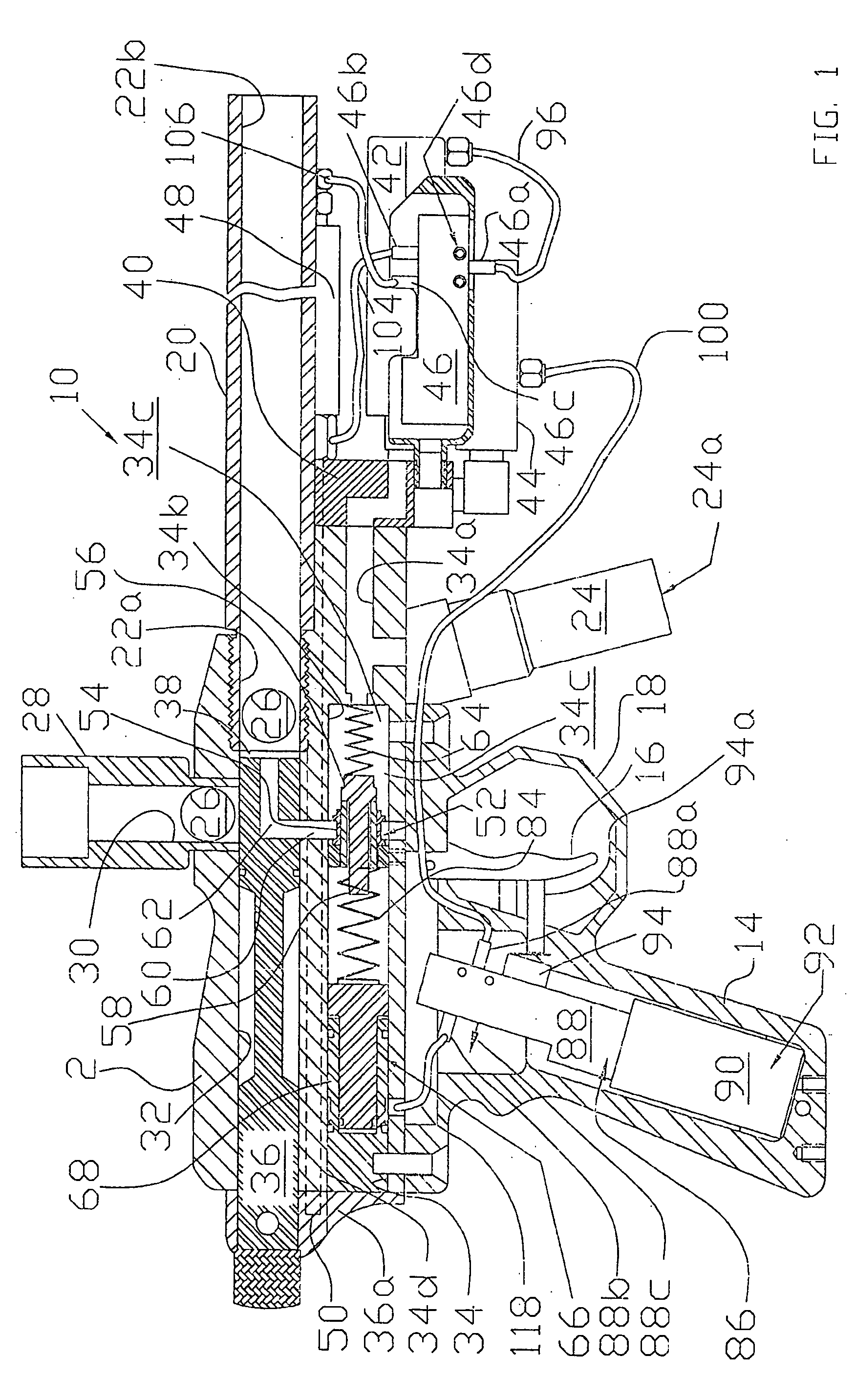

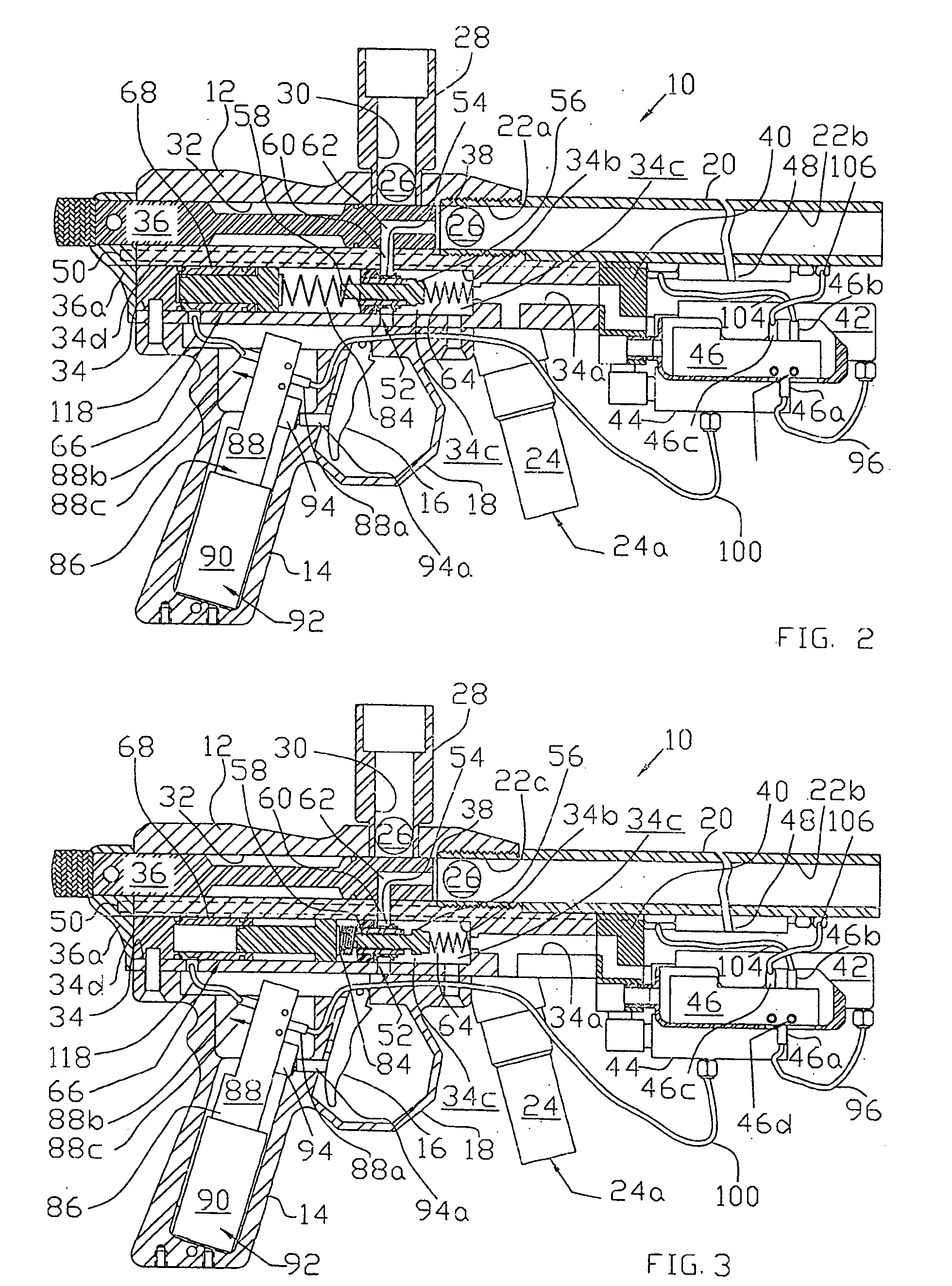

[0020] Referring to the drawing Figures in conjunction with one another, and first considering especially FIG. 1, a paint ball gun 10 includes a main body 12, with a grip frame 14 pivotally carrying a trigger 16 and defining a trigger guard 18. A barrel 20 is attached to the main body 12, and defines a breech opening 22a by which a paint ball is received, and muzzle opening 22b by which a paint ball is discharged. A gas inlet regulator body 24 is also attached to the main body 12, and provides communication via an inlet 24a (arrowed on FIG. 1) with a source of high pressure gas (not shown in the drawing Figures) for powering the paint ball gun 10.

[0021] A paint ball hopper and feeding device (also not seen in the drawing Figures) can be mounted on the top of the main body 12, feeding paintballs 26 into the gun 10 via an upper feed tube 28 defining a feed port 30. The feed port 30 opens into a top one 32 of two substantially parallel and vertically spaced bores (i.e., bores 32 and 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com