Joining system and method for floor boards and boards therefor

a technology of floor boards and joints, applied in the direction of load-supporting elements, structural elements, building components, etc., can solve the problems of one person controlling both ends simultaneously, not always easy to join the boards, and especially difficult to achieve the effect of jointing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

second embodiment

[0045] In FIGS. 7 to 10 a second embodiment is shown. Corresponding parts are denoted by the same reference numerals as in FIGS. 1 to 6 with the FIG. 2 added in front. In this embodiment the shape of the top of the hooks 21 and the corresponding downwardly facing inside of the edge 23 have a different design. Instead of being straight and angled the sides are configured with horizontal surfaces so that the hook 21 has a flat top 25 and the inner side a correspondingly flat abutment surface 26. If the boards should move relative each other horizontally, they will be guided by both the top flat contact surface at 25 and 26, and by the lower flat contact surface at the lower side of the hook 21 and the corresponding upwardly facing inner side of the edge 23. The guiding results in that there will be no difference in height beween the upper surfaces of the boards if the hook 21 should move relative the recess 211.

[0046] The shoulder 27 is shown straight in the figures but may also have ...

first embodiment

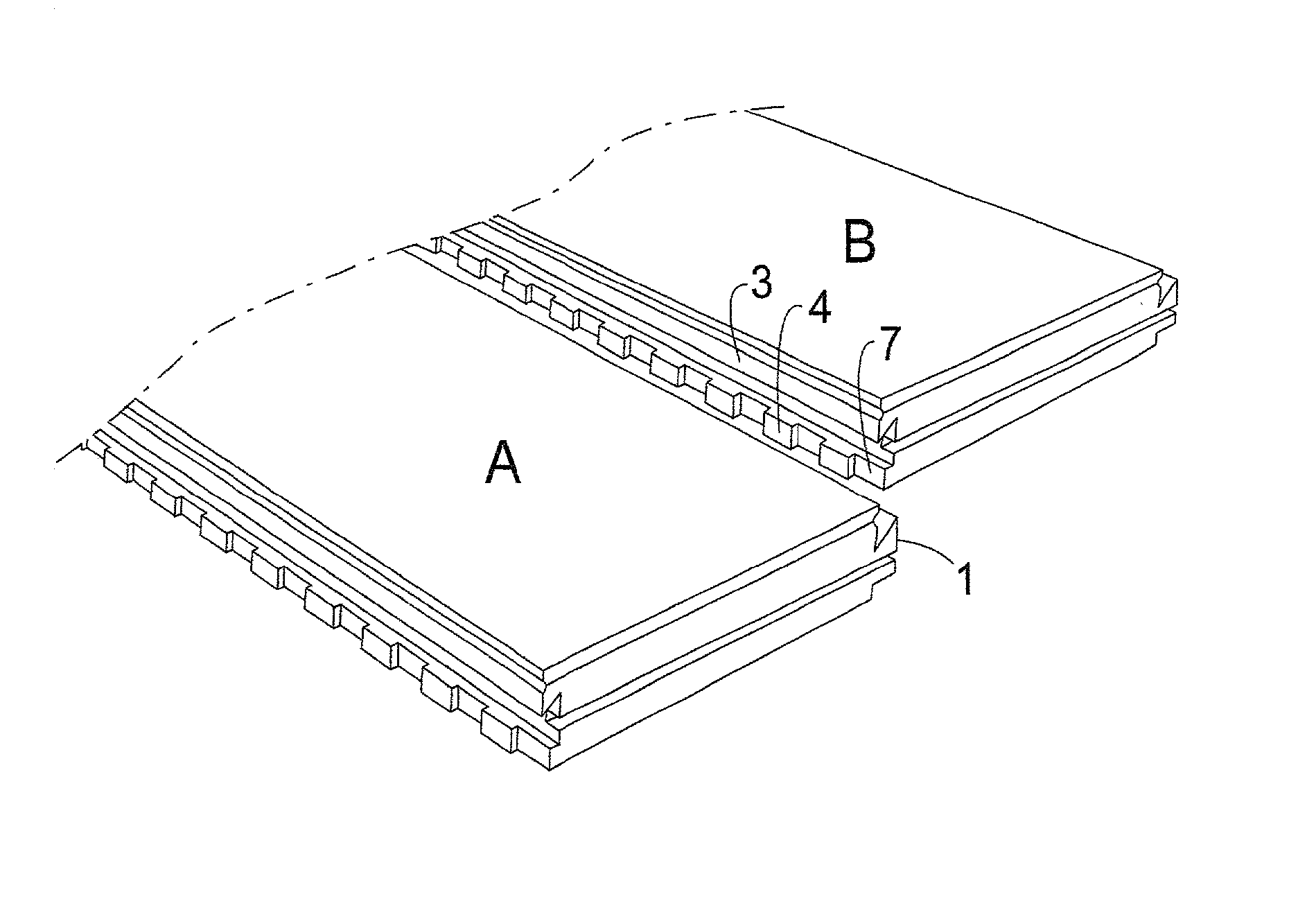

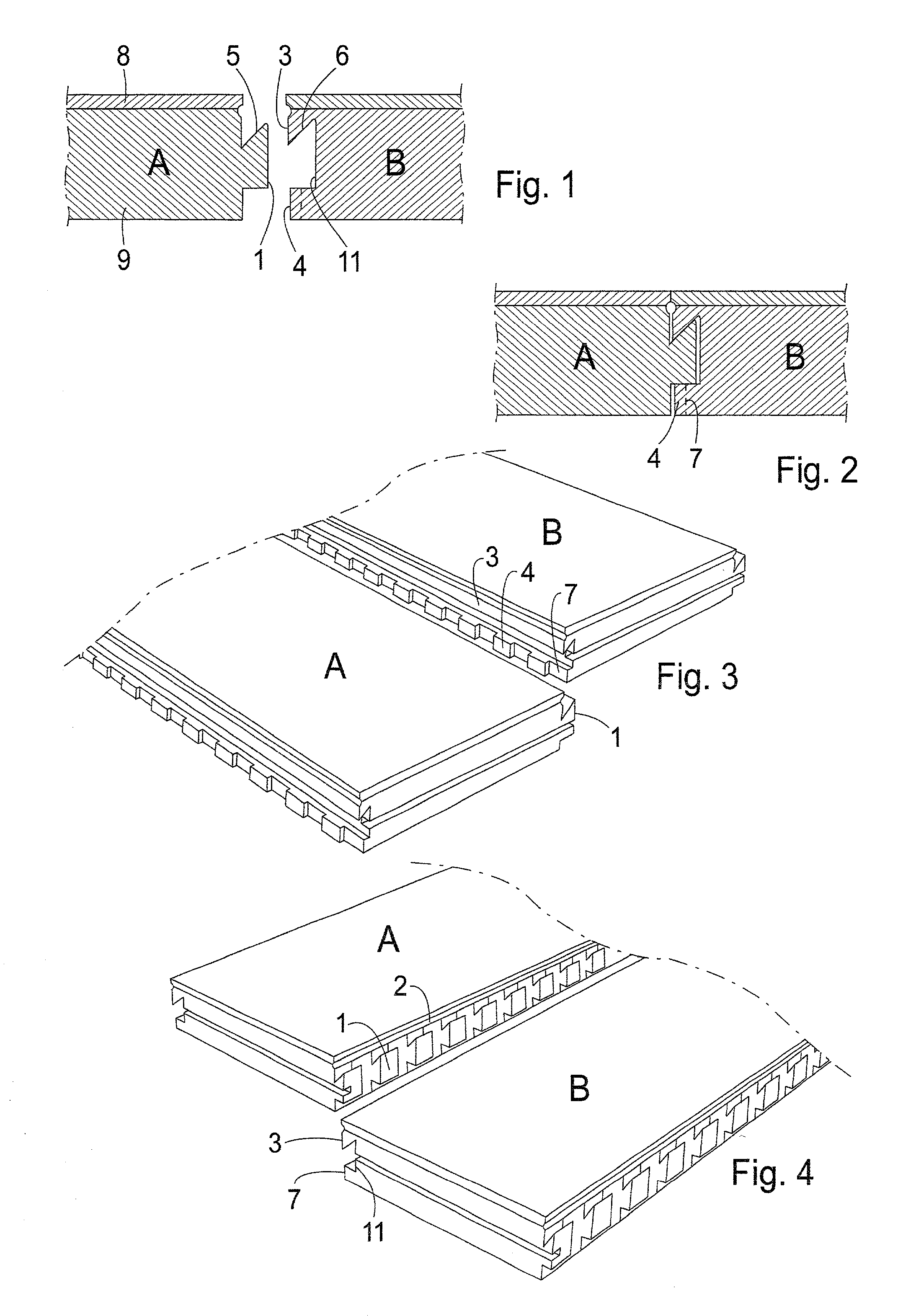

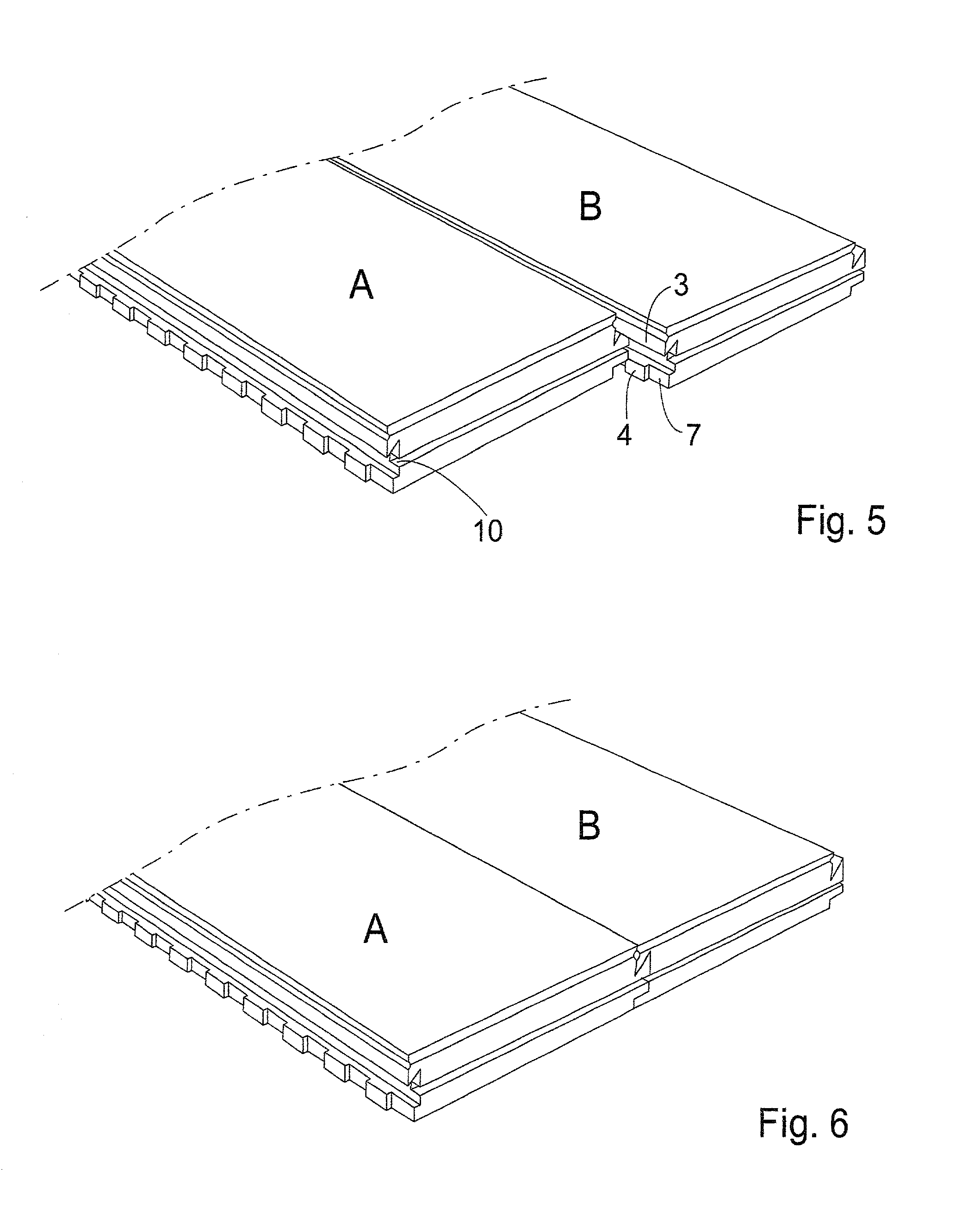

[0064] The short sides of the boards of all the embodiments may be provided with conventional groove-and-tenon joints (or another well known system). This is illustrated in connection with the first embodiment in FIGS. 3, 4, 5 and 6 by a groove 10. The corresponding tenon is located at the other short end and thus is not visible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com