Self-propelled elevator

An elevator and automatic technology, applied in elevators, elevators in buildings, transportation and packaging, etc., can solve the problems of conveying tools and mines occupying a lot of space, manufacturing costs, running costs and maintenance costs, and elevator installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

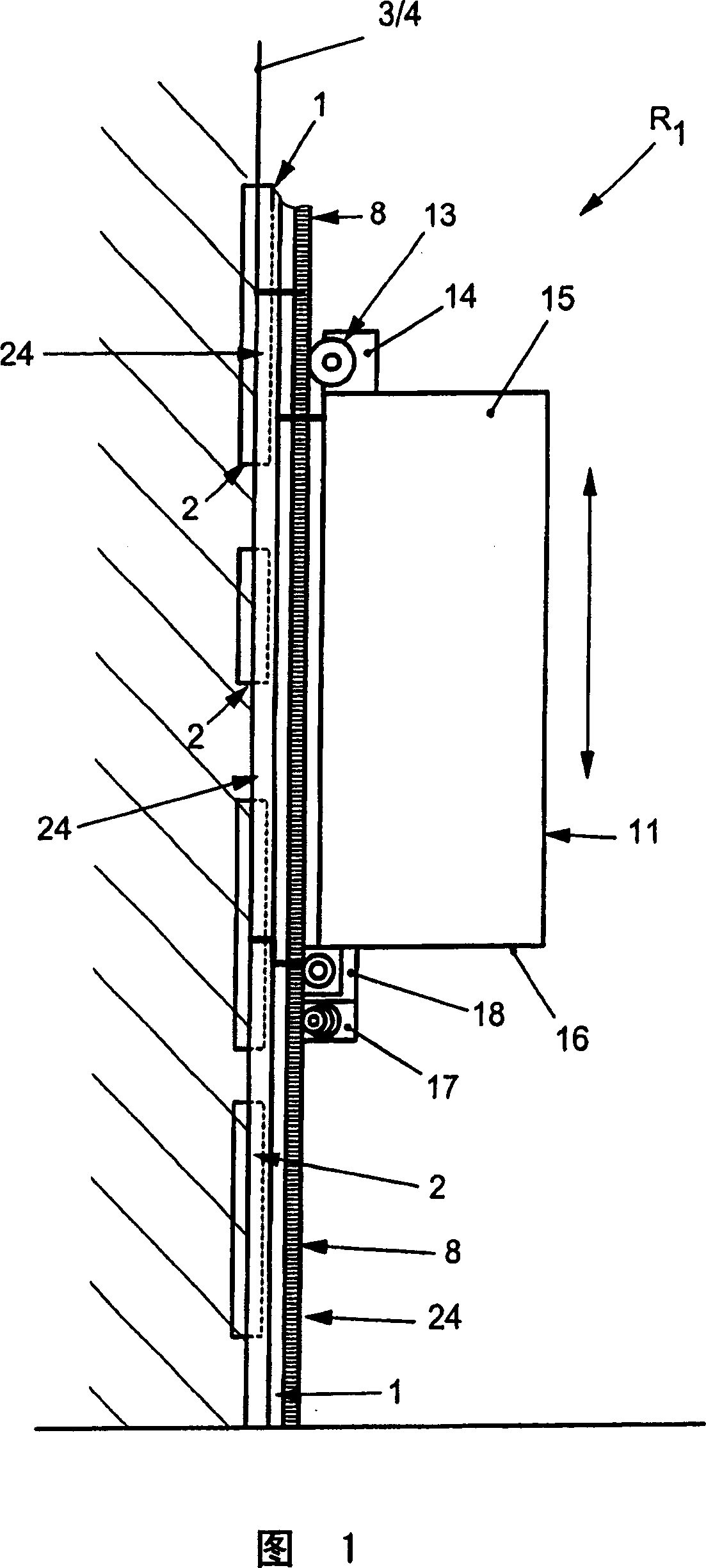

[0026] Figure 1 only shows the automatic elevator R 1 A schematic side view of the main components.

[0027] In this case, at least one driving and / or guide profile 1 is detachably fastened to a structure 3, wall 4 or the like by means of a single fixing profile 2.

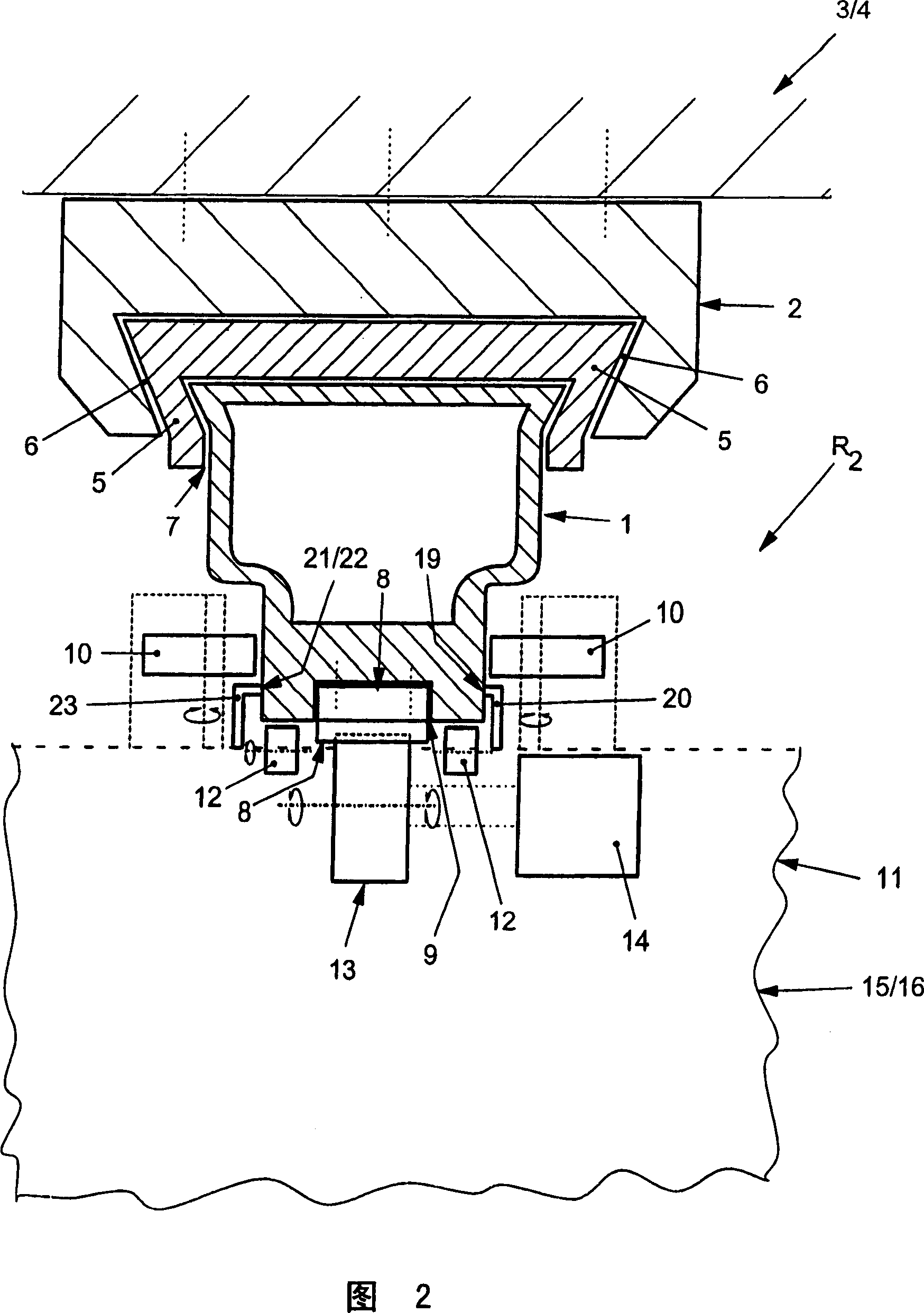

[0028] As shown in the cross-sectional view of FIG. 2, a single fixed profile 2, which is preferably designed to be longitudinal, but can also be clamped, accommodates the driving and / or guide profile 1 in a shock-absorbing manner.

[0029] A rubber bearing 5 is arranged between the fixed profile 2 and the travel and / or guide profile 1.

[0030] Preferably, the fixing profile 2 has a dovetail groove 6. The rubber bearing 5 fits accurately into the groove.

[0031] The driving and / or guide profile 1 is inserted into a gap 7 in a shock-absorbing manner and facing the fixed profile 2. The driving and / or guide profile 1 is hollow in cross section, but it can also be an open profile.

[0032] In this case, the fixing profi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com