Pressure maintaining device for static pressure pile machine

A technology of static pressure pile driver and pile driver, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., and can solve the problems affecting the normal use of static pressure pile driver, piles hugging and pressing into the ground, slipping, etc., to achieve Achieve automatic correction, ensure normal work, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

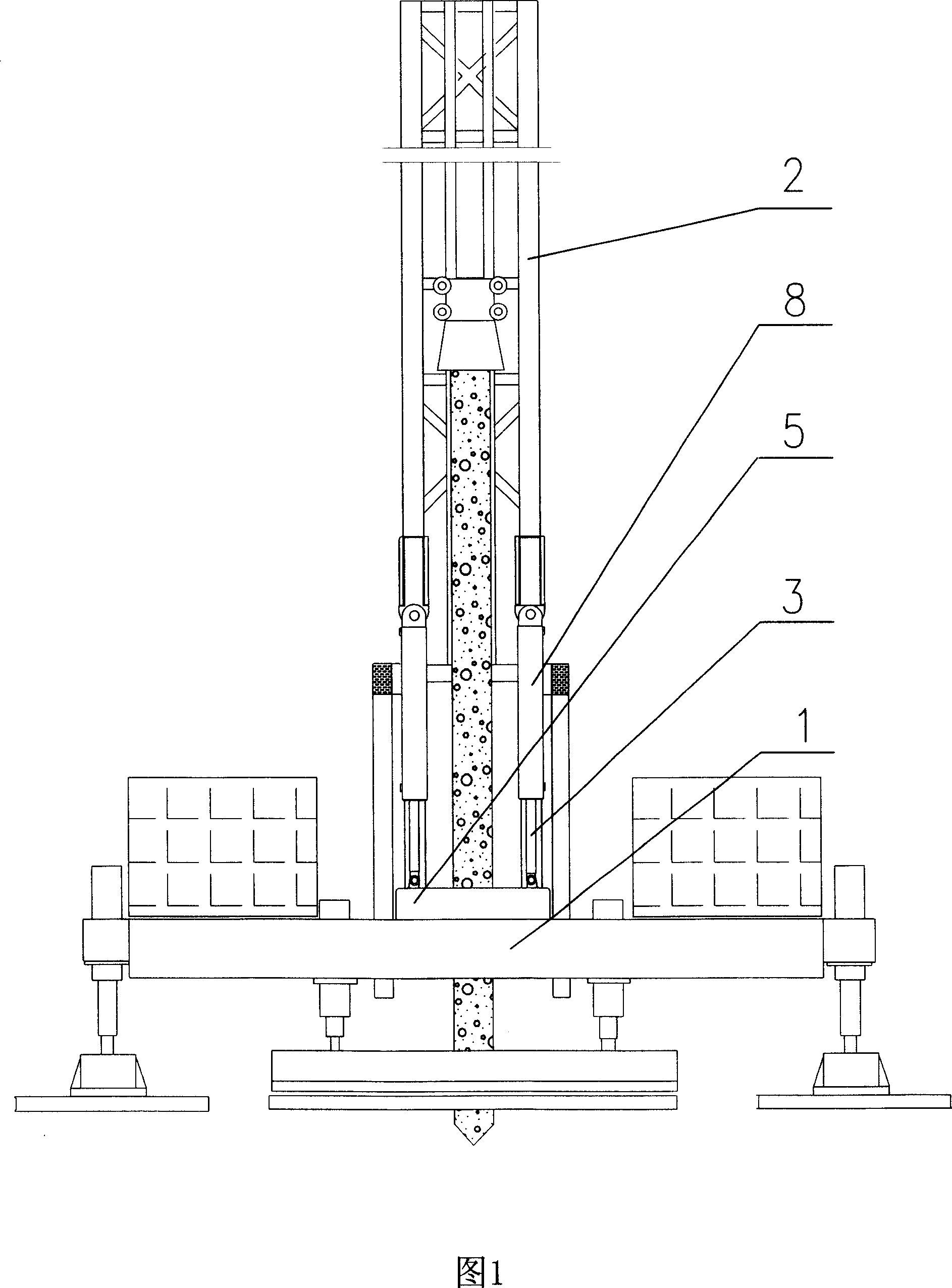

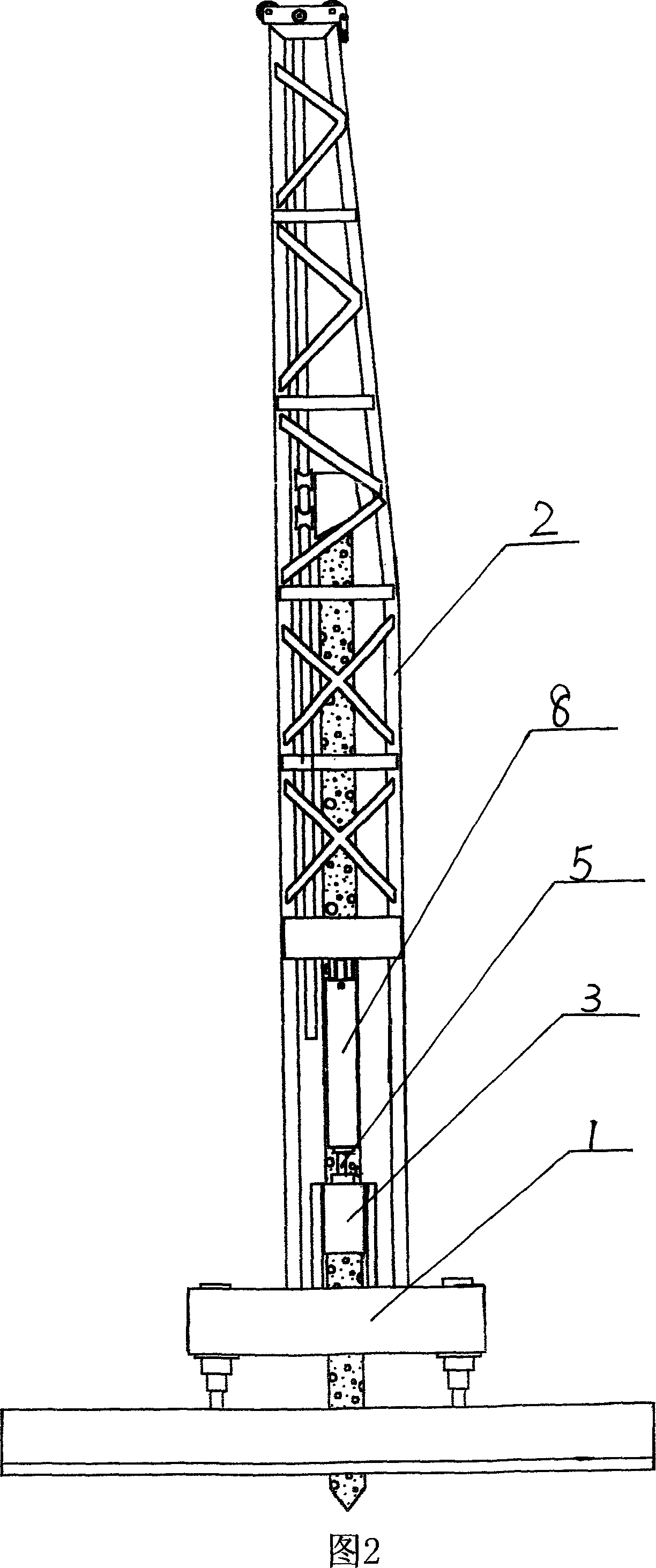

[0023] As shown in Figures 1 and 2, a kind of holding pressure device of static pressure pile machine, comprises the frame 2 that is arranged on the pile machine base 1, is arranged on the sliding box body 3 of frame 2 inner side bottom, inside the sliding box body 3 An integrated hugging and pressing device is provided, and the bottom of the base 1 is provided with a travel driving device for longitudinal and lateral movement.

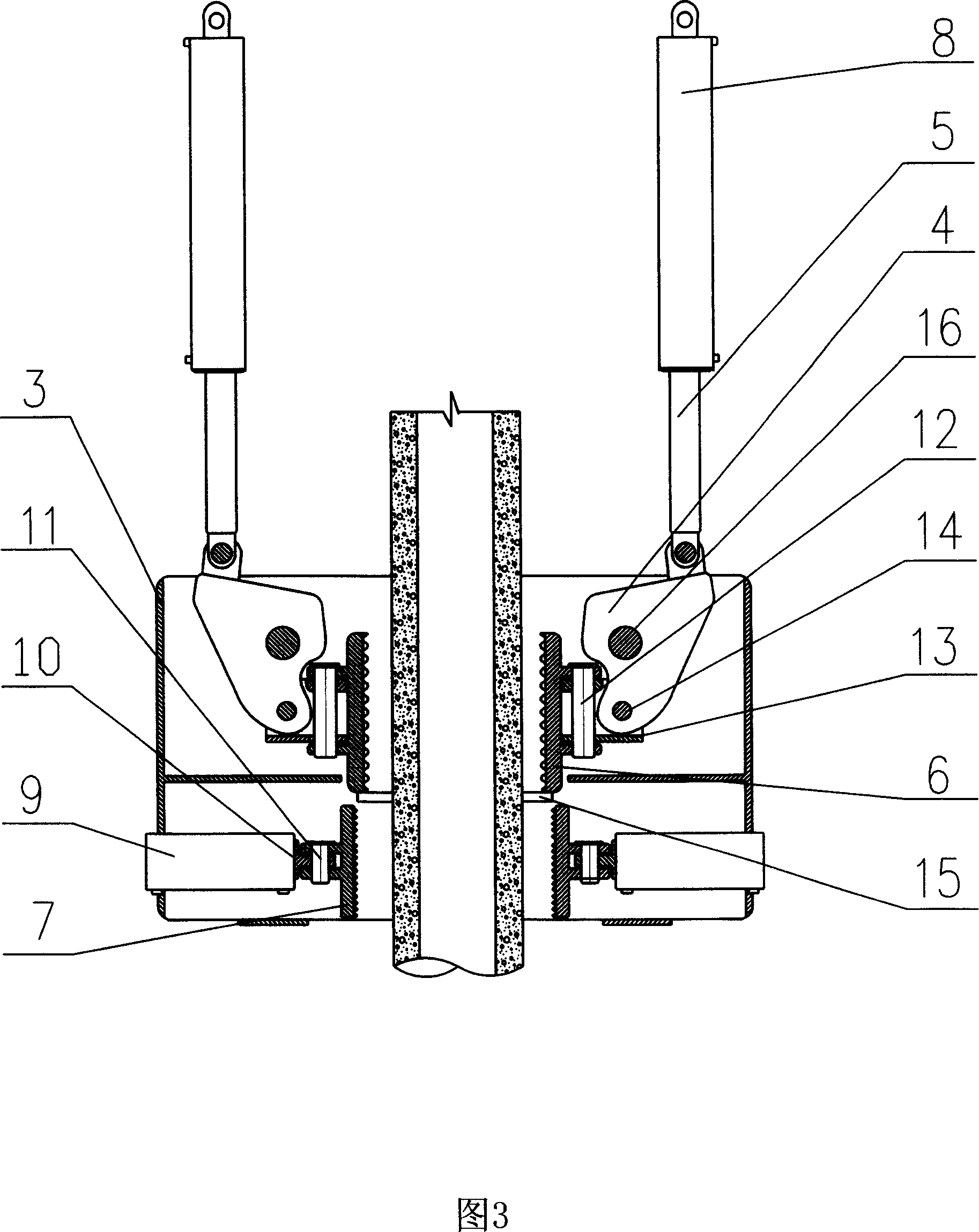

[0024] As shown in Figures 3, 4 and 5, a pair of swinging parts 4 are respectively hingedly connected to both sides of the sliding box body 3, and one side of the hinge joint of the two swinging parts 4 is hingedly connected to the lower end of the telescopic rod 5 respectively, and telescopic The upper part of rod 5 is connected with the power transmission device that is arranged on the frame 2 respectively, and described power transmission device is a pair of hydraulic cylinders 8, and the cylinder body of hydraulic cylinder 8 is respectively fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com