Device for combining several printed webs

A technology for substrates and formats, applied in the directions of sending objects, transporting and packaging, folding thin materials, etc., can solve problems such as plate registration errors and offsets, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

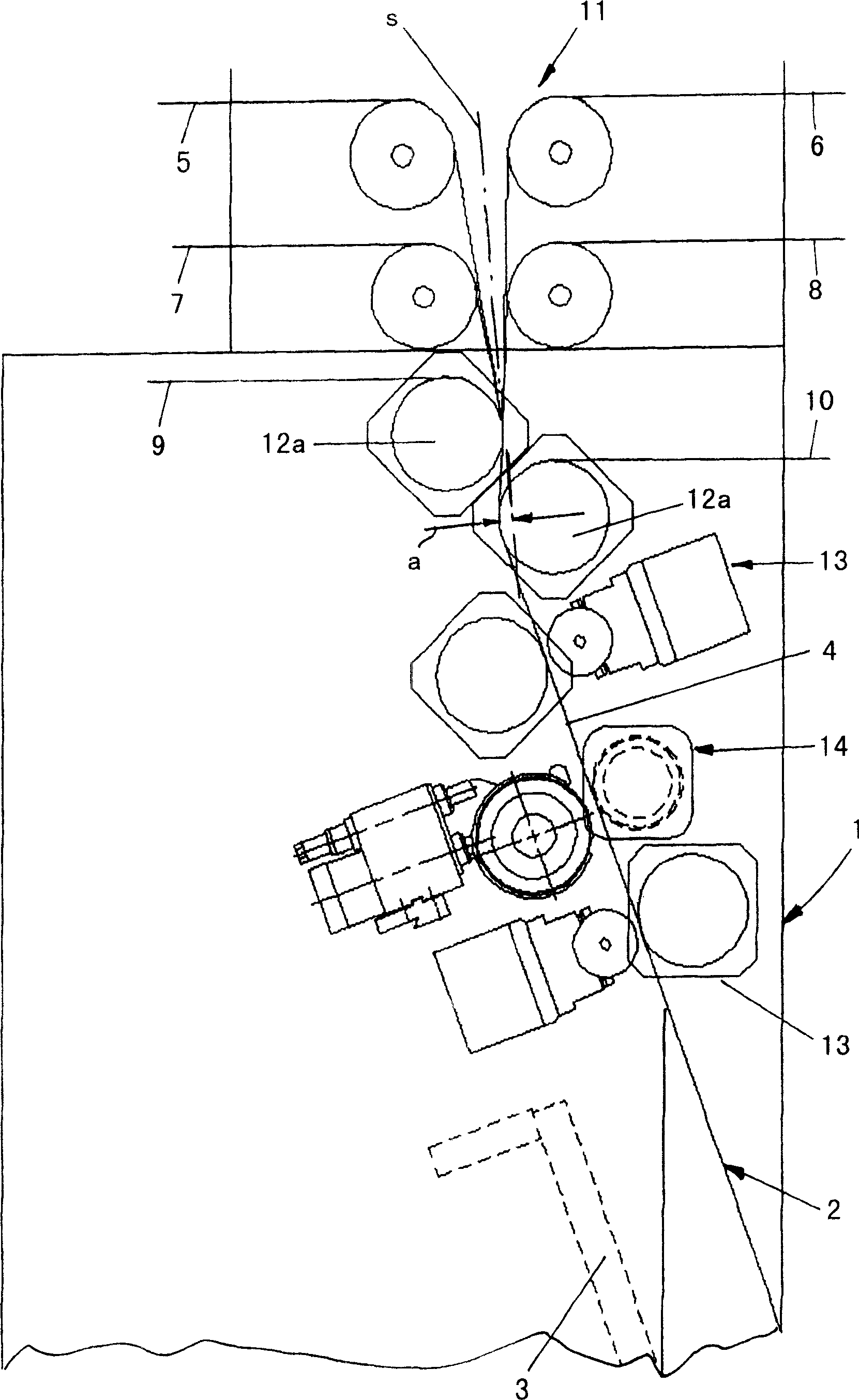

[0012] The figure shows the upper region of a folding mechanism 1 . Usually, a plurality of folding formers are arranged across the width of the folding mechanism 1, one of which, one folding former 2, can be seen in the drawing. The folding former is usually fastened in an adjustable manner on a cross member 3 that runs continuously over the width of the folding mechanism 1 .

[0013] A web web 4 formed from a plurality of webs stacked on top of one another is fed to the folding former 2 . The aforementioned web can be a printing material web from an upstream printing unit. In the exemplary embodiment shown, six printing material webs 5 to 10 are assembled to form a six-layer web web 4 . The lowermost web of the web web 4 sliding on the hinge former 2 is called the funnel web, while the opposite uppermost web is called the cover web. The format between the two is called the intermediate format.

[0014] A so-called guide web 11 arranged in front of the folding former 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com