Method of fast and equably mixing concrete with added magnesium oxide

A magnesium oxide and concrete technology, applied in chemical instruments and methods, clay preparation devices, cement mixing devices, etc., can solve the problems of reduced production efficiency of mixers, increased construction costs, and difficulty in uniform distribution, so as to shorten construction time and improve production Efficiency and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

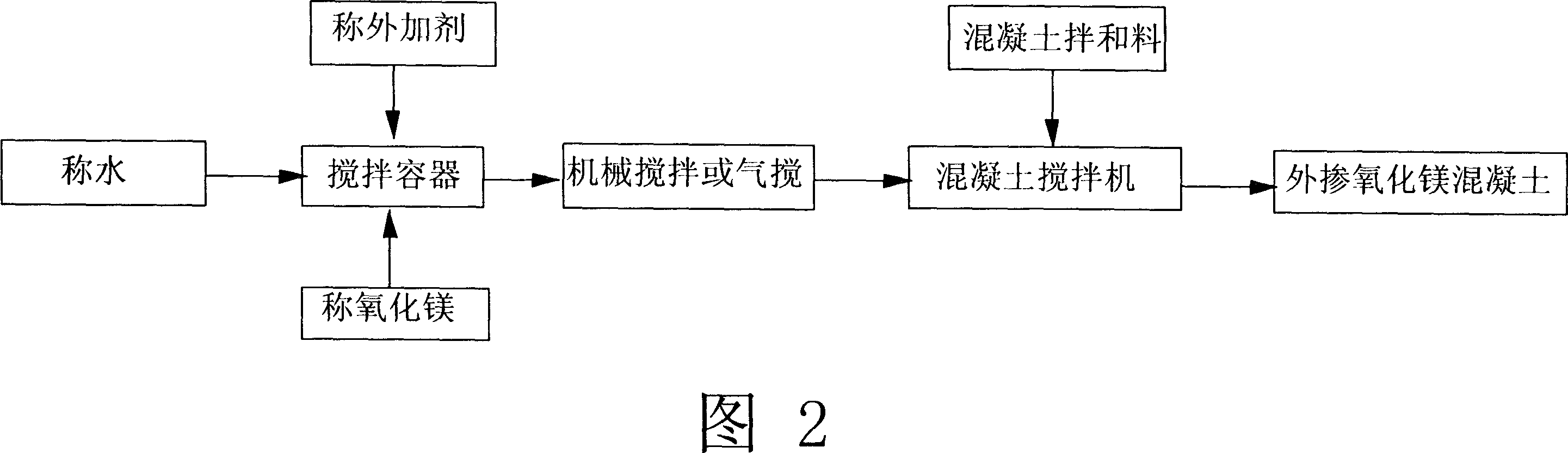

[0013] 1. Quickly and evenly mix the external magnesium oxide concrete process (refer to Figure 2).

[0014] 2. Add the magnesium oxide that needs to be added to each concrete mix into the water and admixture required for each concrete mix and stir quickly and evenly to make a mixed solution of magnesia, water and admixture.

[0015] 3. Add the evenly stirred mixture of magnesia, water and admixture to the concrete mixture in the mixer, and mix it evenly to produce concrete mixed with magnesia within the conventional concrete mixing time.

[0016] 4. Magnesium oxide powder is easy to be stirred evenly in water, but the stability time is short after the stirring is stopped, and precipitation is easy to occur. The stirring method adopts mechanical stirring or pneumatic stirring, and keeps the normal open state.

[0017] Implementation Notes

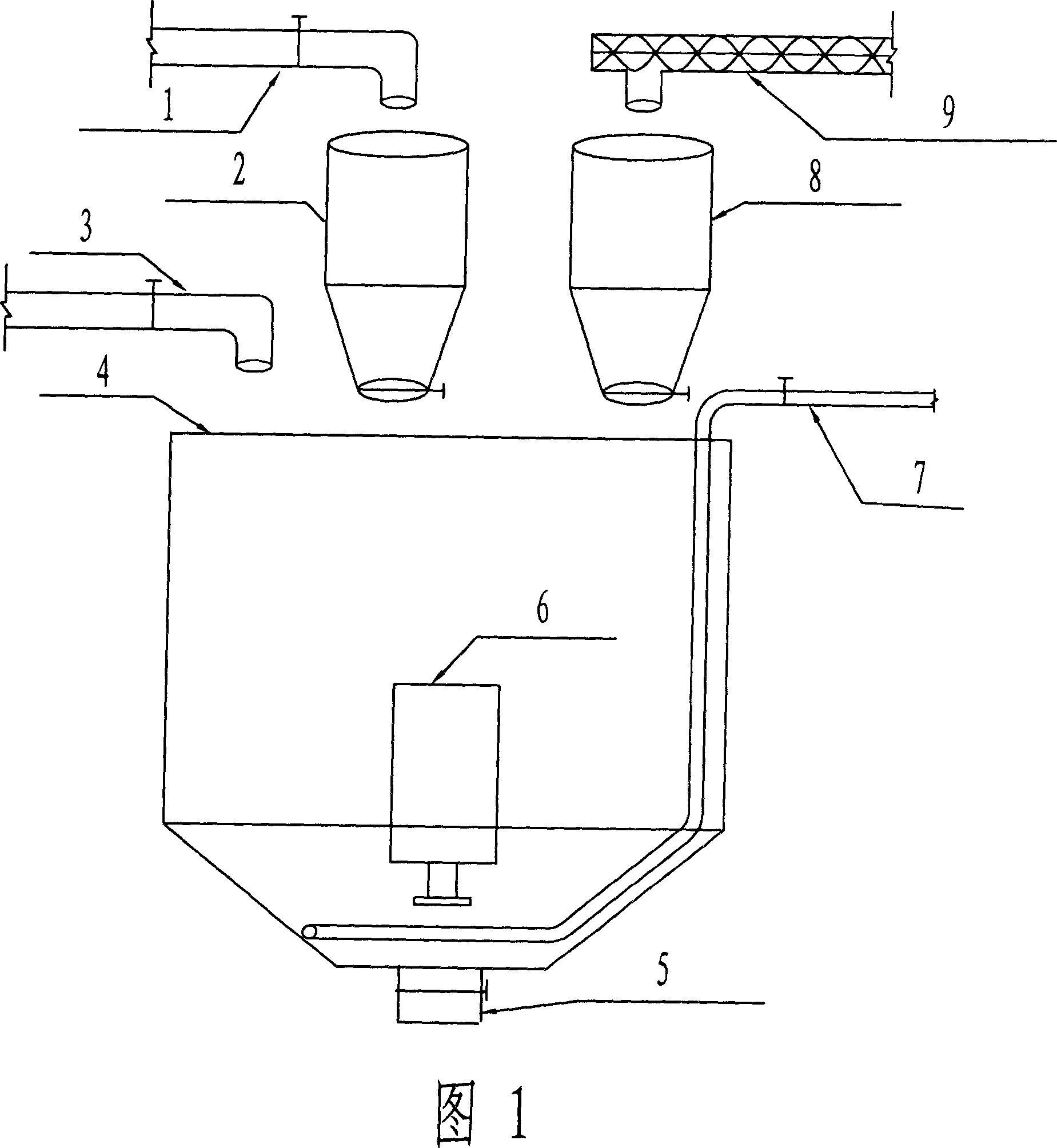

[0018] Weighing water, admixture, and magnesium oxide are completed by the electronic scale of the mixing material system, and the weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com