Method of reference counting before cable tower segmental face machining

A benchmark calculation and cable tower technology, applied to measuring devices, instruments, optical devices, etc., can solve the problems of low marking accuracy, complicated operation process, and unusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

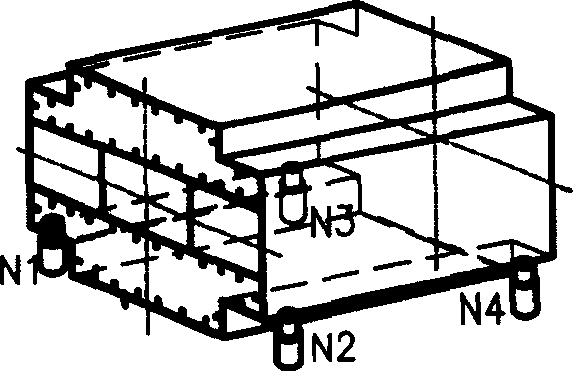

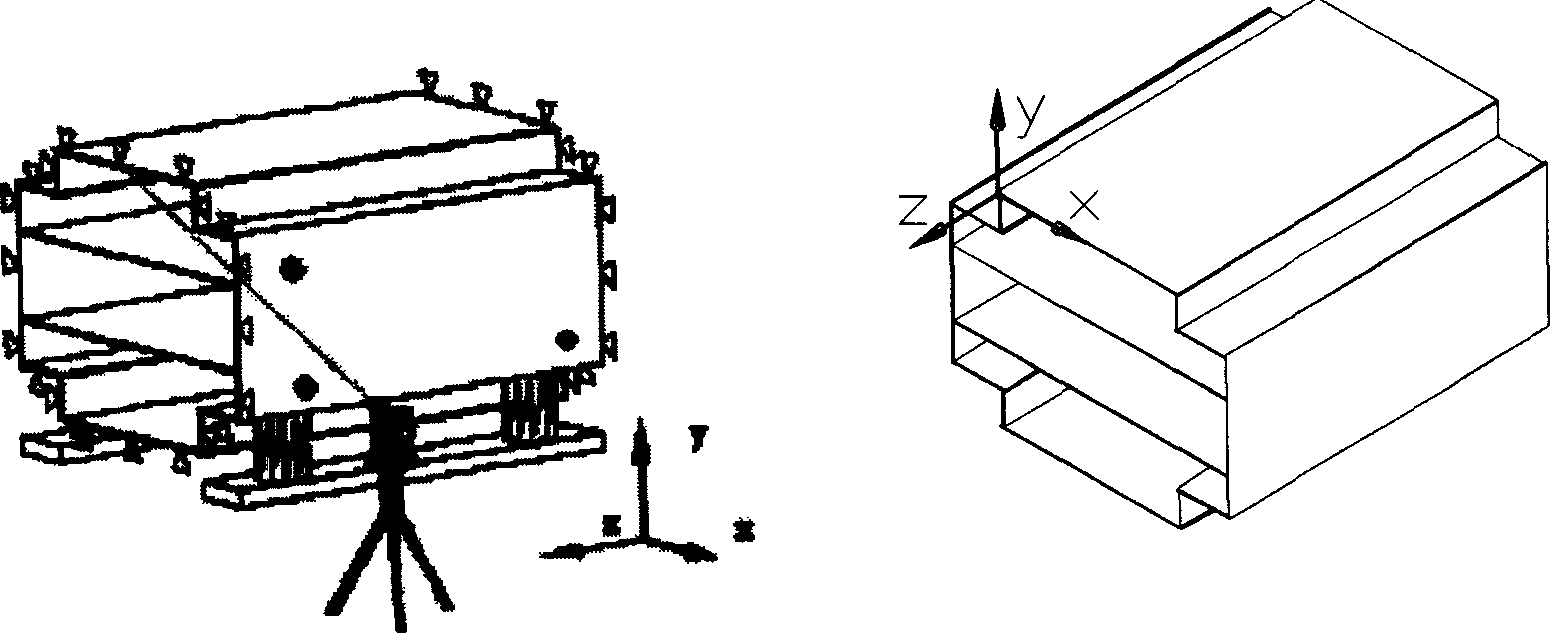

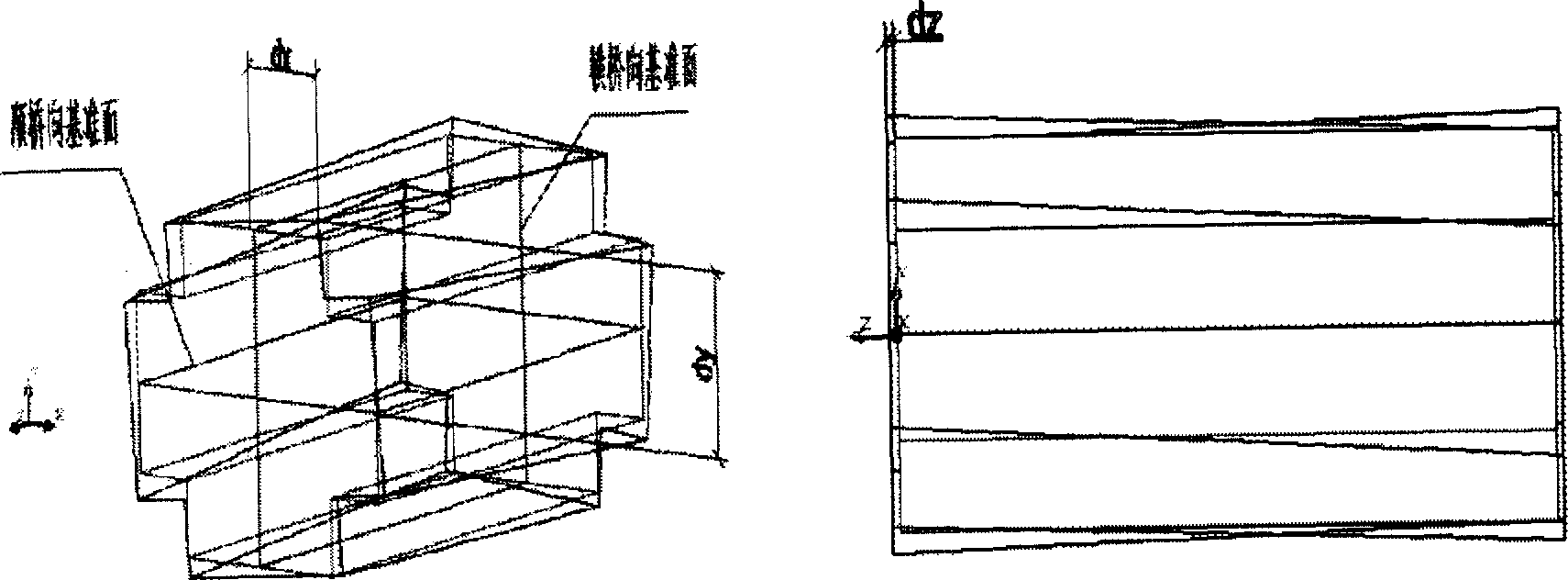

[0039] Embodiment 1: with reference to attached Figure 1~5 . Steel cable tower segmental space measurement method, (1) workpiece state control:

[0040] ① Requirements for supporting reaction force:

[0041] | N 1 - N 2 | N 1 + N 2 ≤ 0.05 ,

[0042] In the formula, N1 and N2 represent the support reaction force, N1-N2 represents the support reaction force difference, N1+N2 represents the support reaction force sum,

[0043] | N 3 - N 4 | N 3 + N 4 ≤ 0.05 In the formul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com