Safety needle

A needle and body technology, applied in the field of improved safety injection needles, can solve the problems of difficult assembly of safety injection needles, fragile guide rails and locking mechanisms, and difficulty in molding collars, etc., and achieves robust design, easy assembly, and reduced assembly. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

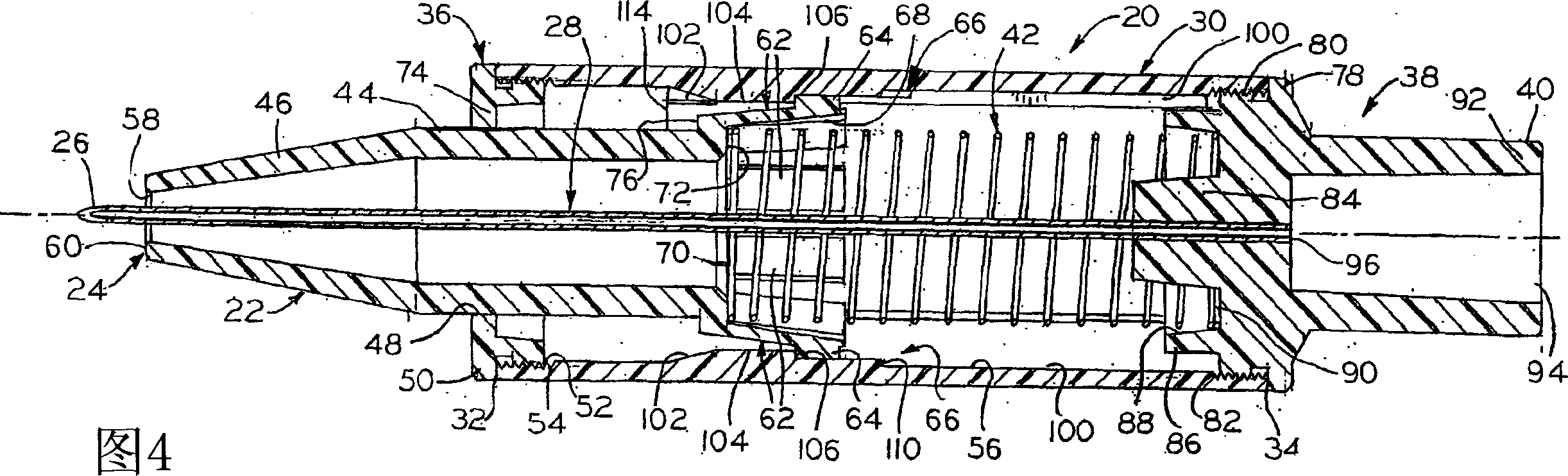

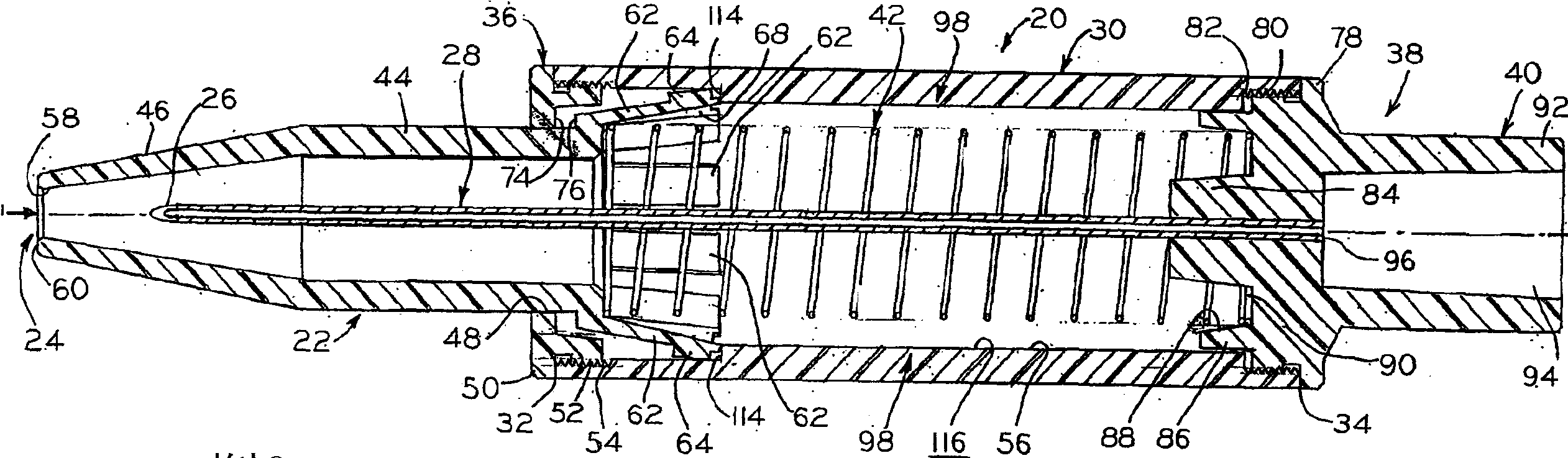

[0047] Referring to Figures 1, 2 and 3, safety injection needle 20 is a modified needle used in conjunction with a typical syringe (not shown). The safety injection needle 20 is provided with a slidable sleeve 22 . Referring to FIG. 1 , the cannula 22 is shown in an initial position in which the tip 26 of the needle 28 emerges from the end 24 of the cannula 22 . Cannula 22 is free to move rearwardly against the bias of spring 42 but cannot move toward needle tip 26 . When using the safety injection needle 20, the needle end 26 is inserted into the patient so that the cannula end 24 contacts the patient's skin. As the needle continues to be inserted, the cannula 22 retracts to the position of FIG. 2 . In this position, cannula 22 remains in contact with the patient so needle 28 is not exposed. Once the safety needle 20 has been used and removed from the patient, the cannula 22 is slid back to a fully extended position. The sleeve 22 extends outwardly beyond the initial posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com