Electromagnetic flow sensor of non-insulated measuring pipe

A technology of electromagnetic flow and measuring tubes, which is applied in the application of electromagnetic flowmeters to detect fluid flow, volume/mass flow generated by electromagnetic effects, etc., which can solve problems affecting accurate flow measurement and difficulty in applying electromagnetic flow sensors, etc., and achieve easy application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation plan

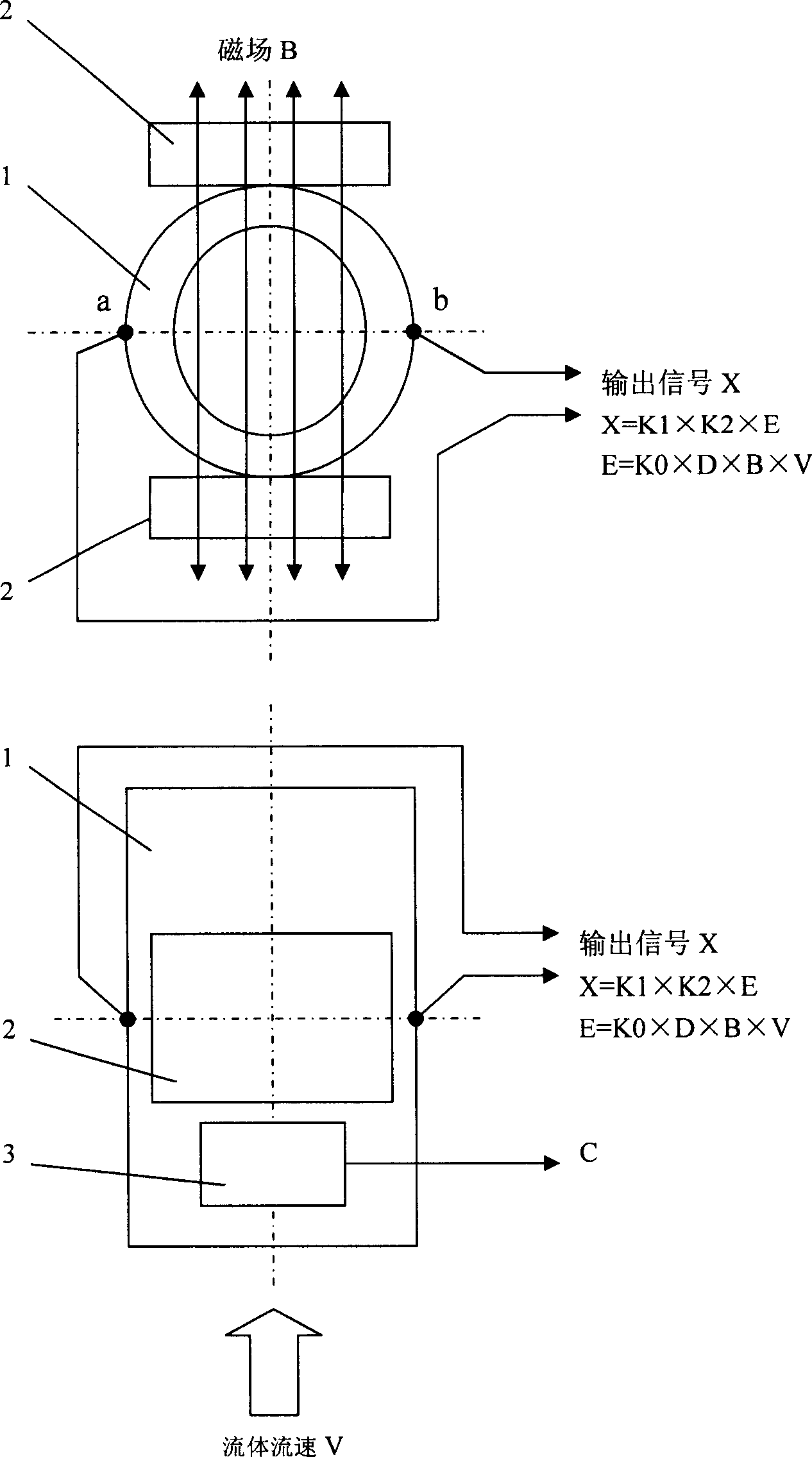

[0018] A preferred embodiment of the present invention is as follows: see figure 1 .

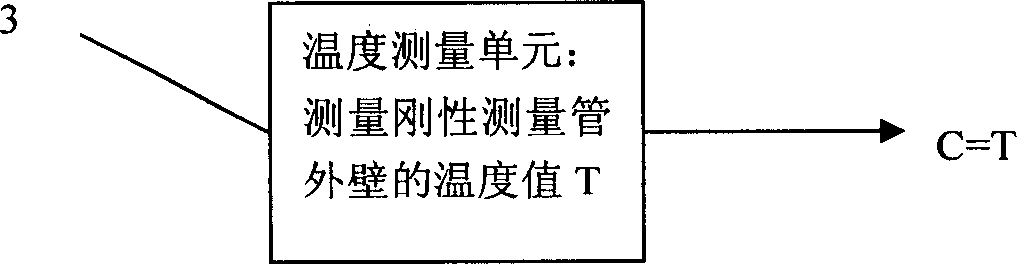

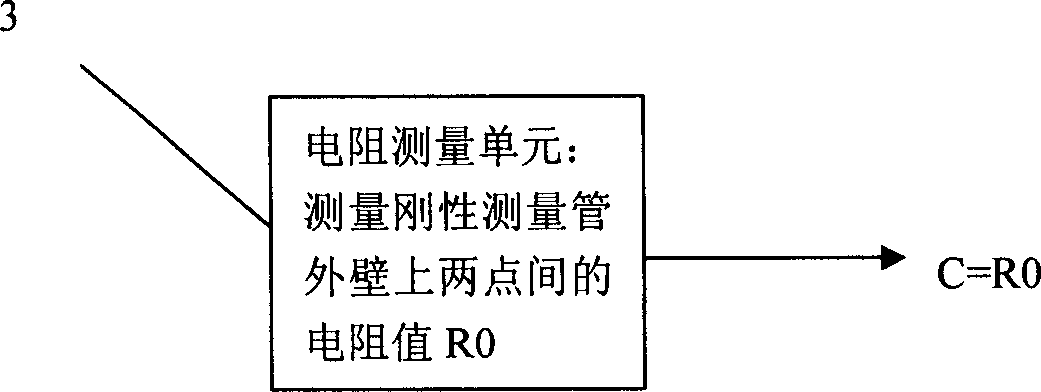

[0019] The electromagnetic flow sensor of the non-insulated measuring tube includes a rigid measuring tube 1 whose internal diameter is D for the flow of the measured fluid, and an excitation unit 2 that generates a magnetic field B perpendicular to the flow direction of the fluid on the rigid measuring tube 1; The fluid in the rigid measuring tube 1 has a flow velocity V. Under the action of the magnetic field B, the fluid in the rigid measuring tube 1 generates an induced potential E, E=K0×D×B×V, and K0 is a coefficient; it is characterized in that in the magnetic field B There are two measuring points a and b on the outer wall of the rigid measuring tube 1 within the scope of action, which directly leads to the output signal X for measurement, X=K1×K2×E, K1 is in the rigid non-insulated position with the two points a and b A position-dependent coeff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com