Electric wiring case

A technology for electrical junction boxes and wires, which is applied to electrical components and other directions to prevent damage, improve rigidity, and achieve miniaturization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

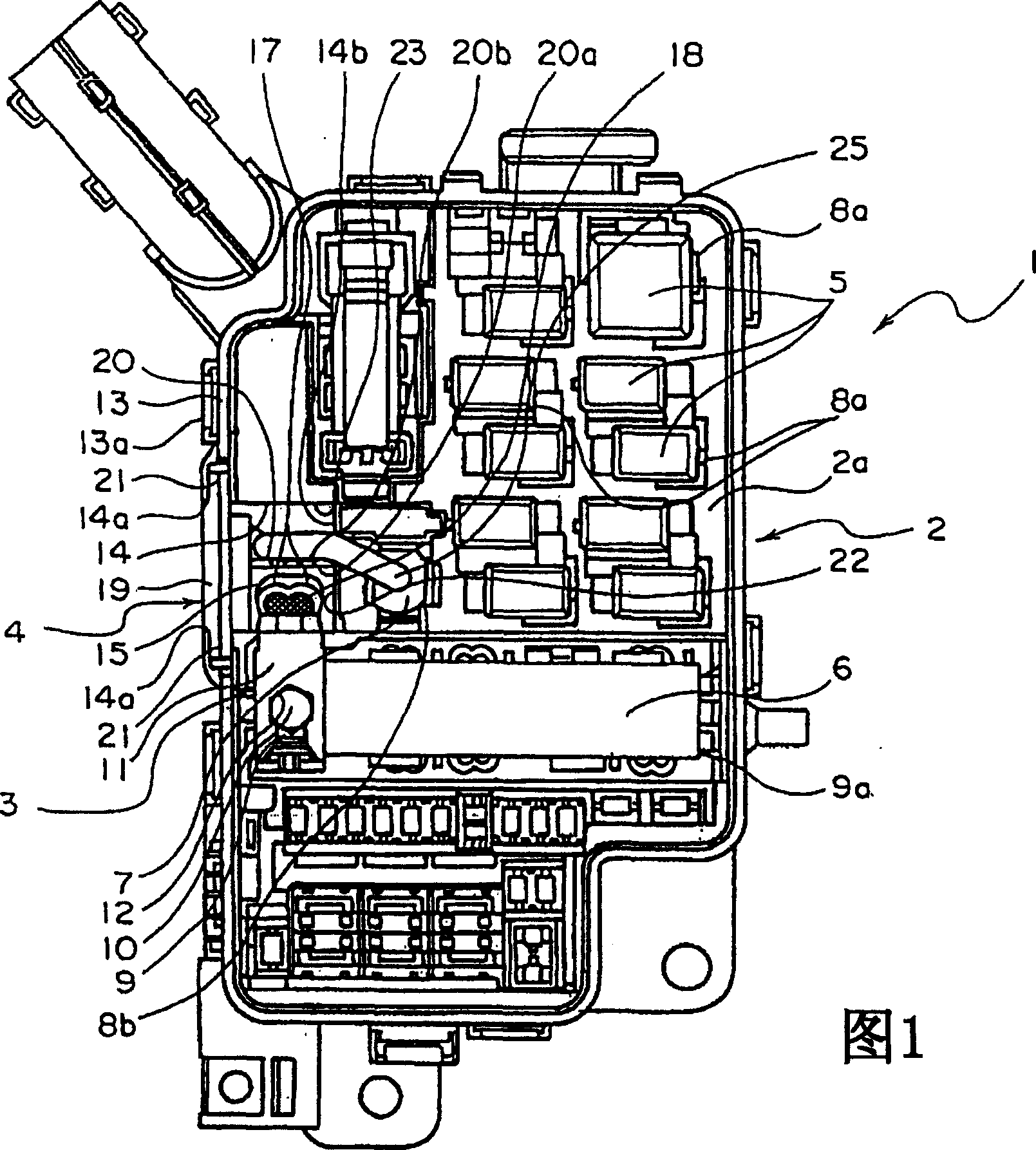

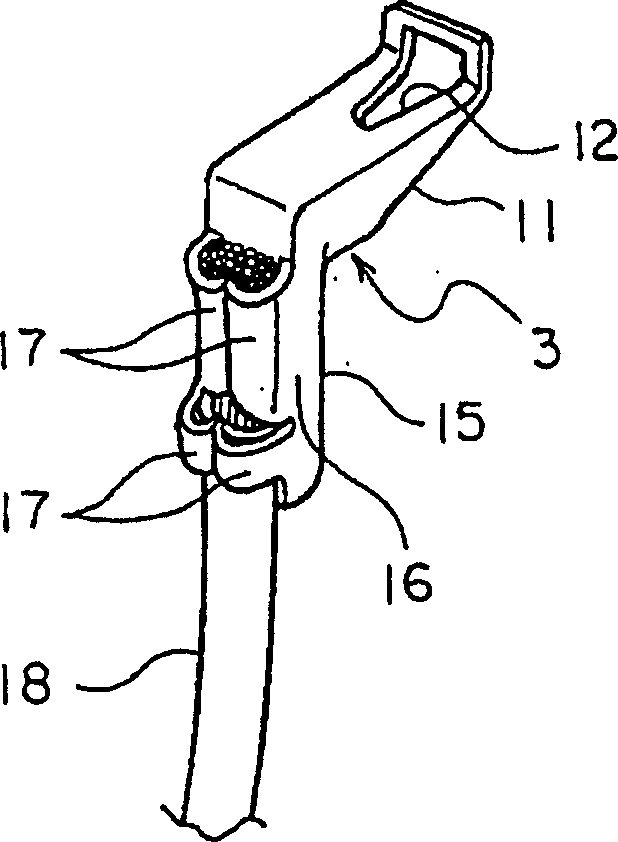

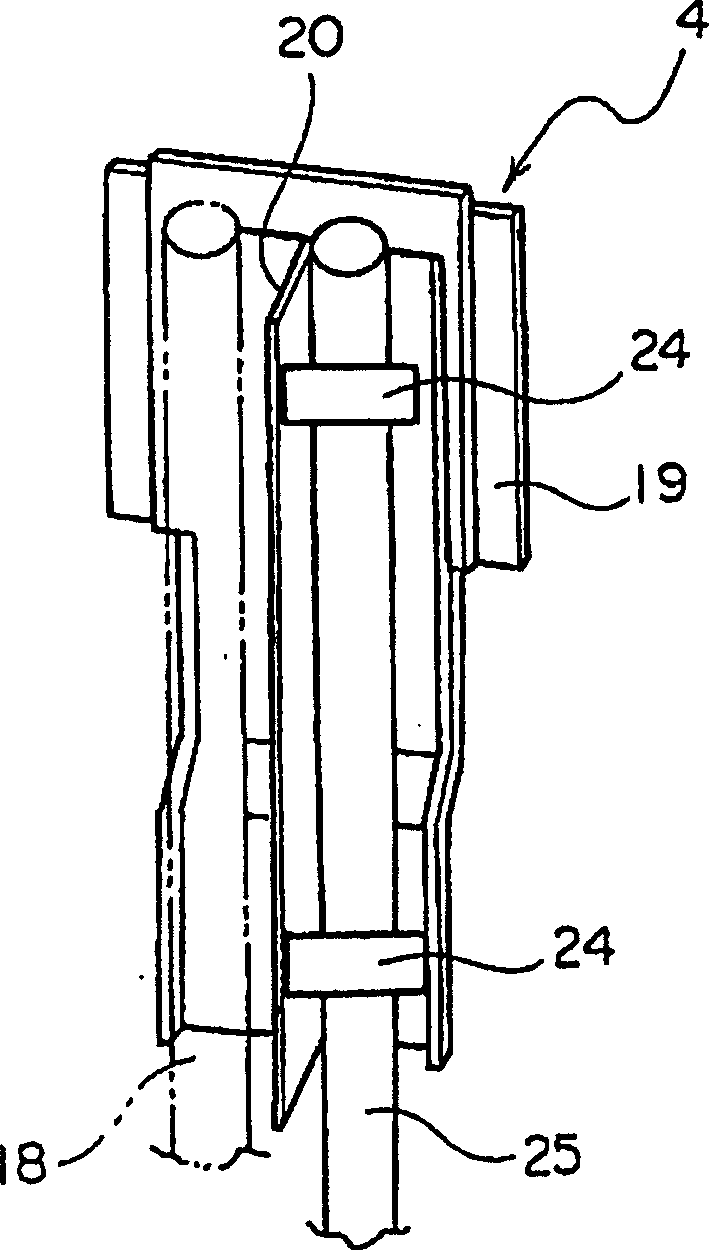

[0036] Below, according to Figure 1 to Figure 5 , an electrical junction box according to one embodiment of the present invention will be described. The electrical junction box 1 shown in FIG. 1 according to this embodiment is mounted on an automobile as a mobile body.

[0037] As shown in FIG. 1 , the electrical junction box 1 has a box main body 2 , a wiring tray not shown, terminal fittings 3 , side covers 4 , and the like. The box main body 2 is made of insulating synthetic resin, and is molded by known injection molding. The box main body 2 is formed in a cylindrical shape (box shape) by a plurality of outer walls 13 .

[0038] In addition, on the upper surface (corresponding to the surface) 2a of the box main body 2 on the front side in FIG. Electrical components such as a melting ring 6 and a connector 7 as an electrical component are fitted. Nuts (not shown) screwed to the bolts 10 are buried in the terminal mounting portion 9 . The terminal fitting part 9 is for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com