Boiler plate heating device and method

A boiler and plate technology, applied in boiler water pipes, metal material coating process, coating, etc., can solve problems such as shape distortion, difficulty in referencing auxiliary parts, and failure to consider bimetallic deformation, etc., to achieve stable bending and plane Good degree of straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

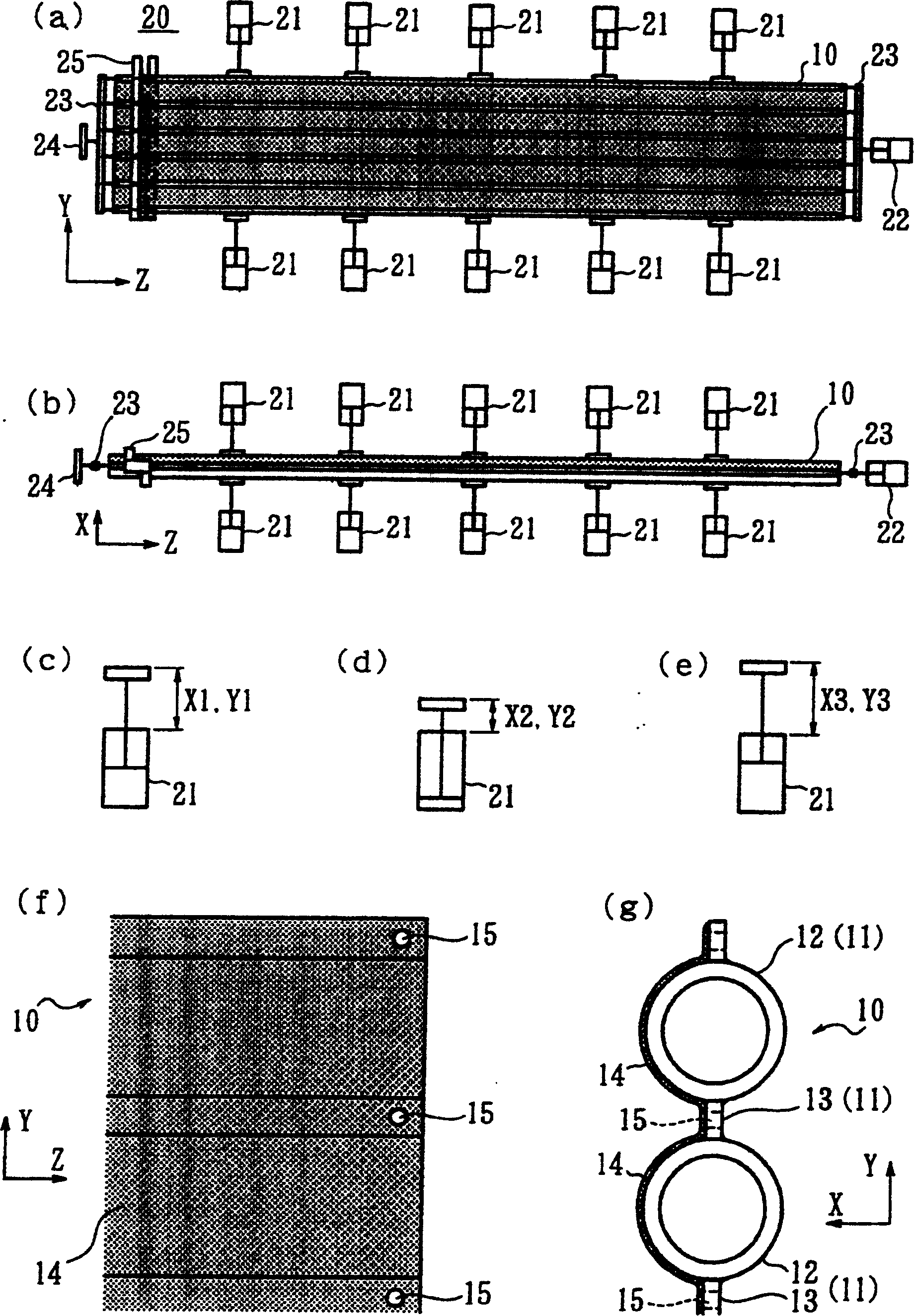

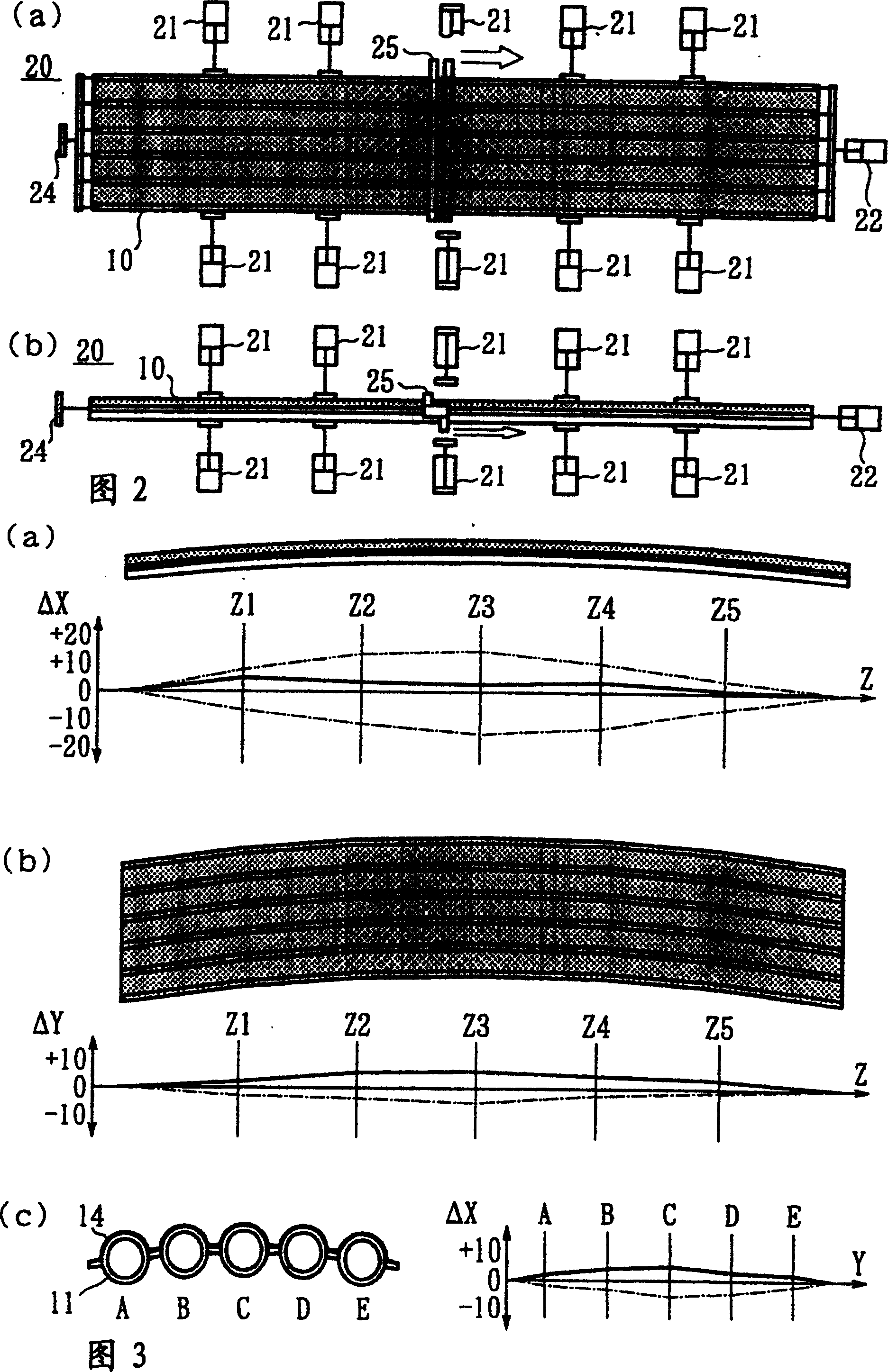

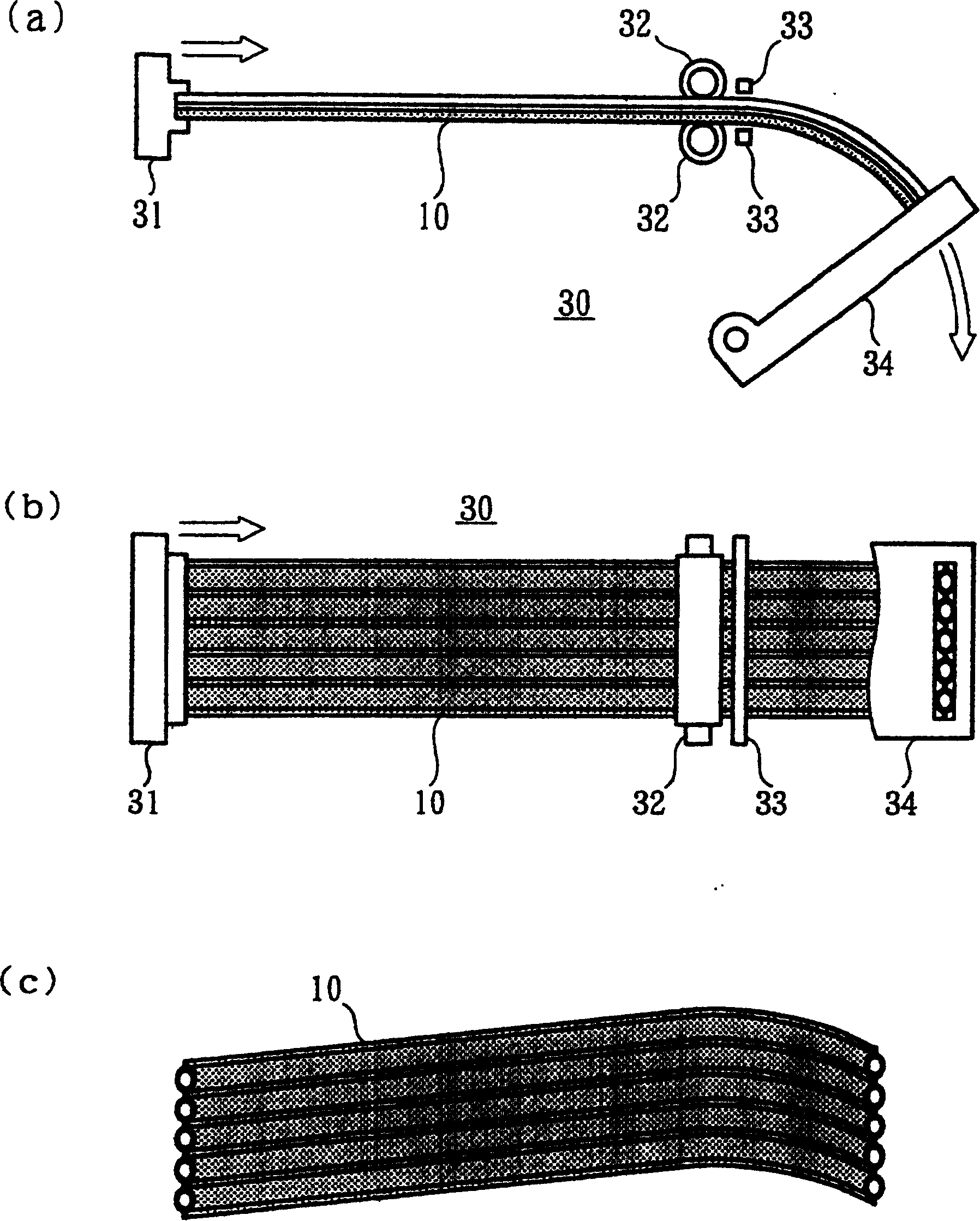

[0057] One embodiment of the boiler plate heating device of the present invention will be described with reference to the drawings.

[0058] figure 1 (a) is a schematic appearance (plan view) of the cladding layer side after the boiler plate 10 is placed in the boiler plate heating device 20, (b) is a schematic appearance (side view) of the lateral side side, (c) to (e) It is a symbolic view of the position forcing cylinder 21 for shape adjustment, (f) is an enlarged view of the corner portion of the cladding surface of the boiler plate 10, and (g) is an enlarged view of a part of the end surface of the plate 10.

[0059] The boiler plate heating device 20 (refer to figure 1 (a) and (b)) are extended high-frequency induction heating devices of the mobile heating method. As a well-known basic part, there is an induction body 25 as a heating action body for local heating, and the heating device is supplied via a cable. An unillustrated power supply unit for its high frequenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com