Continuous loading vickers

A technology of Vickers hardness and indenter, which is applied in the direction of testing the hardness of materials, etc., can solve the problems of non-continuous and unsatisfactory loads, and achieve the effect of making up for the weight structure Vickers hardness tester and continuous loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

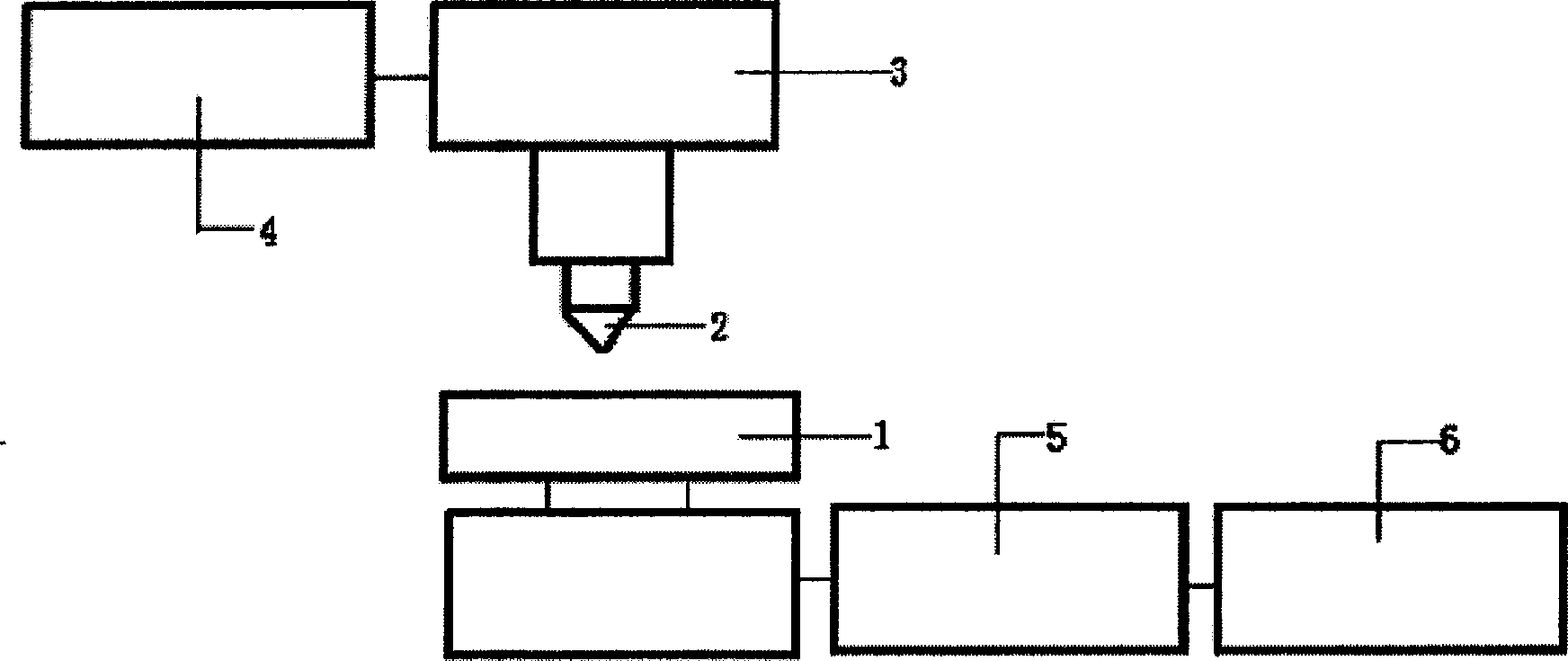

[0017] A pressure sensor (3) is installed on the pressure head (2), and the force value display device (4) is directly connected to the pressure sensor (3), and the pressure head (2) is connected to the lifting platform (1) through the displacement of the lifting platform (1). A pressure is generated between the pressure sensor (3) to display the pressure value between the pressure head (2) and the lifting platform (1) on the force value display device (4).

Embodiment 2

[0019] A pressure sensor (3) is installed on the pressure head (2), and the force value display device (4) is directly connected to the pressure sensor (3), and a power device is installed on the lifting platform (1), and the power device includes a stepping power supply (5) and the control device (6), the stepping power supply (5) is adjusted through the control device (6), so that the lifting platform (1) is continuously displaced, and the sample is under pressure between the lifting platform (1) and the pressure head (2). The pressure value is displayed in the force value display device (4) through the pressure sensor (3).

Embodiment 3

[0021] Install the pressure sensor (3) on the lifting platform (1), connect the force value display device (4) to the pressure sensor (3), connect the power device to the lifting platform (1), and the power device includes a stepping power supply (5) and a control device (6). Adjust the stepping power supply (5) through the control device (6), so that the lifting platform (1) is continuously displaced, so that the sample generates pressure between the lifting platform (1) and the indenter (2), and the pressure value is passed through the force display device (4) DISPLAYED.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com