Electric clippers

An electric clipper and electromagnet technology, applied in metal processing and other directions, can solve problems such as aggravating noise and increasing operator discomfort, and achieve the effects of reducing vibration energy, vibration noise, and vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

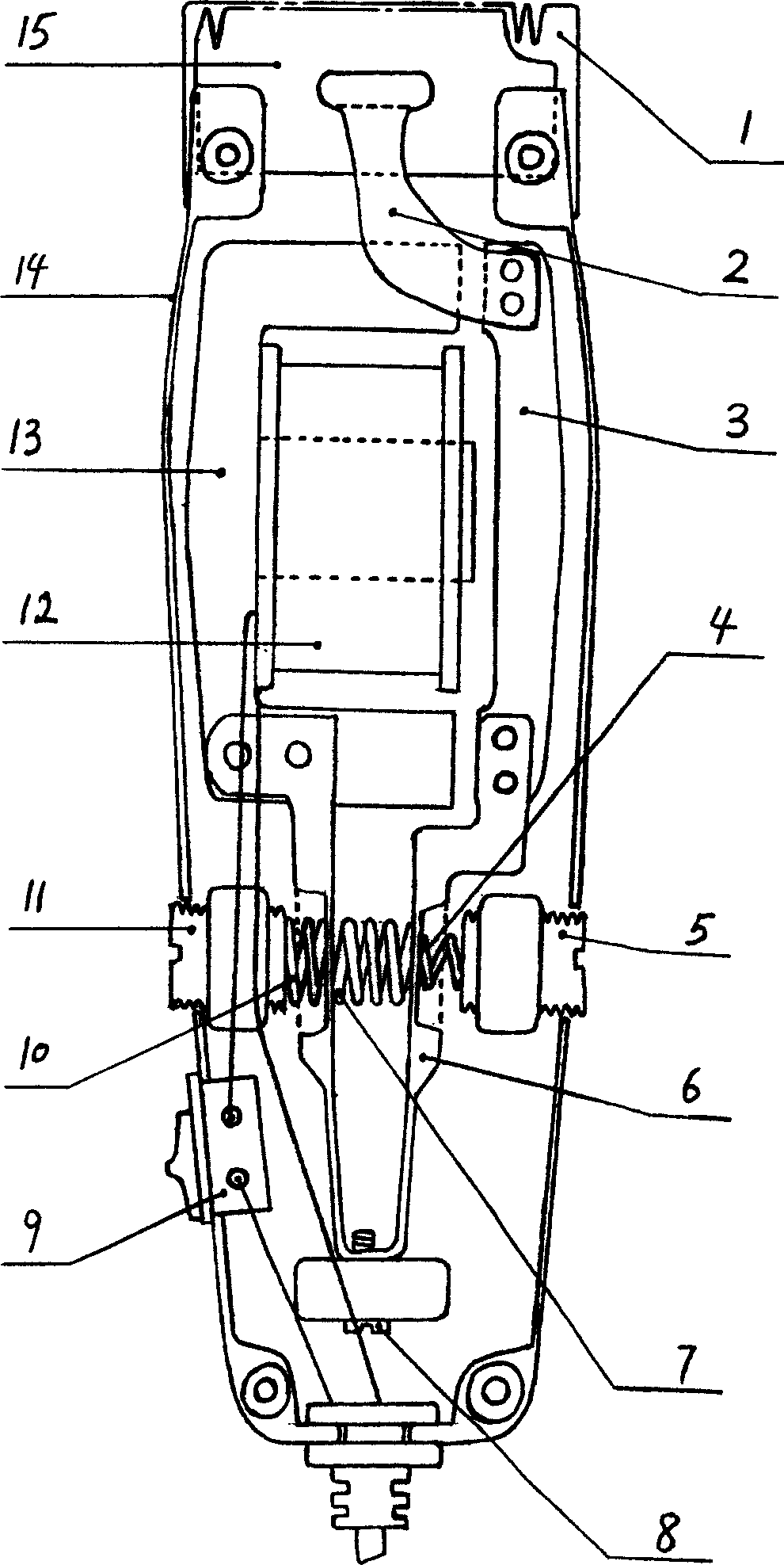

[0017] One embodiment of the present invention is as follows: the housing 1 is made of plastic molding. The fixed blade 1 is made of a metal material, and the front end is provided with scissor teeth. The fixed blade is fixed to the front end of the housing by screws. Moving blade 15 adopts metal material to make, and front end has scissors, has hole in the middle of moving blade, and its effect is to insert for the wear-resistant plastic of leaf spring 2 front ends, and wear-resistant plastic also plays further safe insulating effect. Since the upper ends of the leaf spring 2 and the armature 3 are fixedly connected, the left and right swing of the armature will drive the left and right movement of the movable blade through the leaf spring 2 . The bracket 6 is made of steel plate stamped and bent into a "V" shape. One branch is fixedly connected to the lower end of the electromagnet core 13, and the other branch is fixedly connected to the lower end of the armature 3. The lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com