Apparatus for manufacturing rod-shaped tobacco products with a filter, in particular filter cigarettes

A technology for tobacco products and filters, applied in the manufacture of cigarettes, tobacco, applications, etc., can solve the problems of long installation length and increased noise of the driving device, and achieve the effect of increasing arrangement density, easy assembly, and compact assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The apparatus described below is used in the manufacture of rod-shaped tobacco products, in particular filter cigarettes.

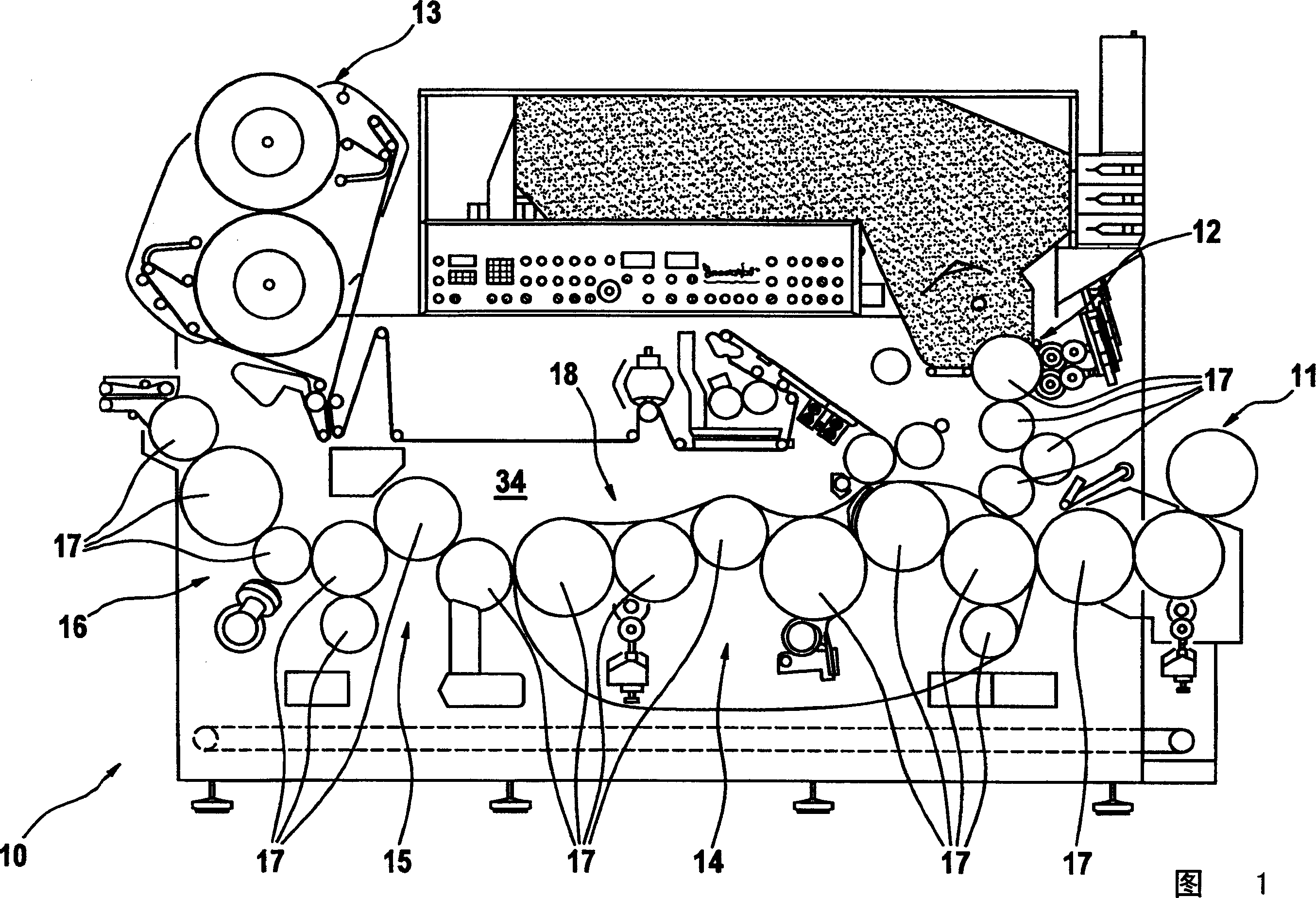

[0014] The device 10 shown in Figure 1 configured as a filter tip attachment machine has different functional units, namely basically comprising a tobacco rod conveying device 11, a filter tip conveying device 12, a covering paper conveying device 13, a cigarette making device 14, a cigarette testing device 15 and Cigarette dispensing device 16. All devices 11 - 16 have a plurality of drums 17 to form a so-called drum train 18 . The drums 17 are arranged adjacent to each other, preferably juxtaposed parallel to each other and generally tangentially in such a way that they are operatively connected to each other.

[0015] All drums 17 can be driven synchronously by the drive system. In an embodiment not shown, a plurality of drums 17 may be driven by a common drive, with at least one drum 17 having separate further drive means 19 . However, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com