Semitone mask coding method for producing microoptical element

A technology of halftone mask and coding method, which is applied to optical components, optics, opto-mechanical equipment, etc., can solve the problems of complex design, difficult to guarantee the surface and axis symmetry of components, and large amount of coded data, and achieves coded data volume. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

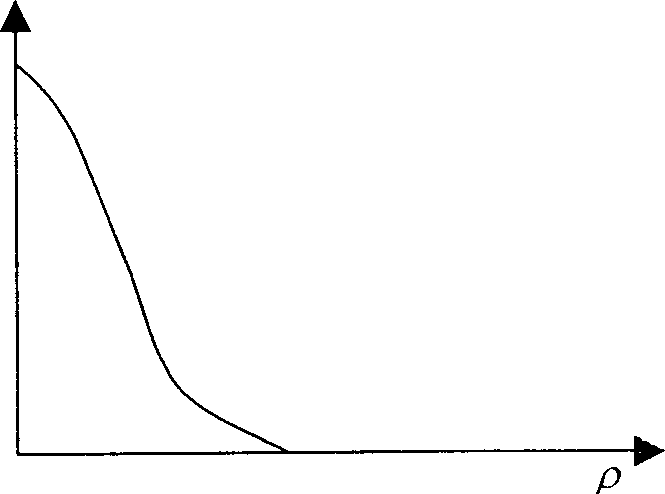

[0032] Such as figure 1 , figure 2 Shown, the encoding process of the present invention is: first to axisymmetric element surface shape function f (r) ( figure 1 with figure 2 shown) to get its spatial spectrum distribution function g(ρ) by Bessel-Fourier transform, from which the highest cut-off frequency B(ρ) of the surface shape function can be determined image 3 shown);

[0033] g ( ρ ) = 2 π ∫ 0 ∞ f s ( r ) r J 0 ( 2 πrρ ) dr - - - ( 1 )

[0034] Then according to the root λ of the zero-order Bessel function i (i=1, 2,...) and the ratio of the highest cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com