Vacuum demand valve

A valve and vacuum chamber technology, applied in the field of vacuum demand valves, which can solve problems such as high cleaning costs and fluid overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

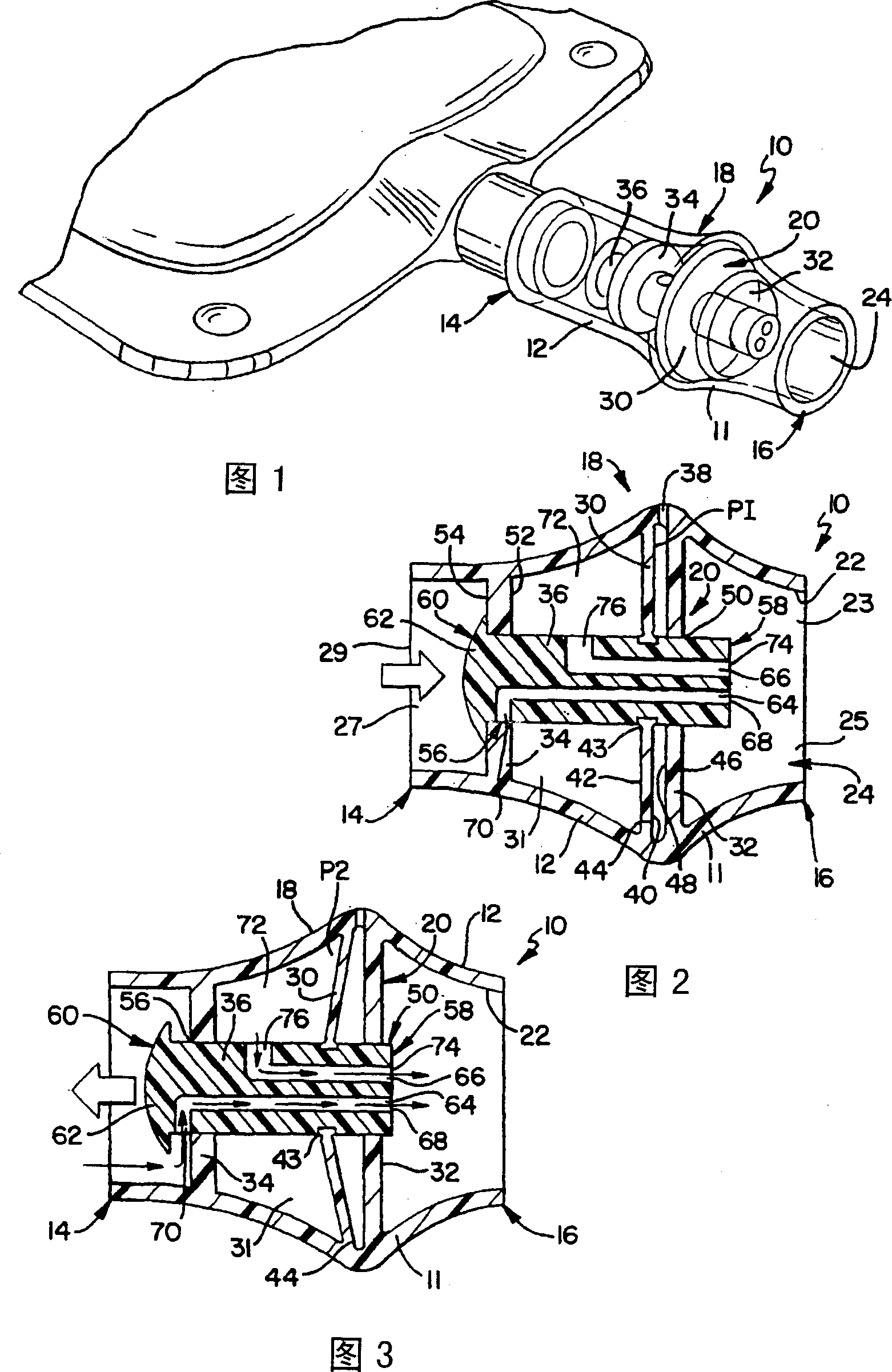

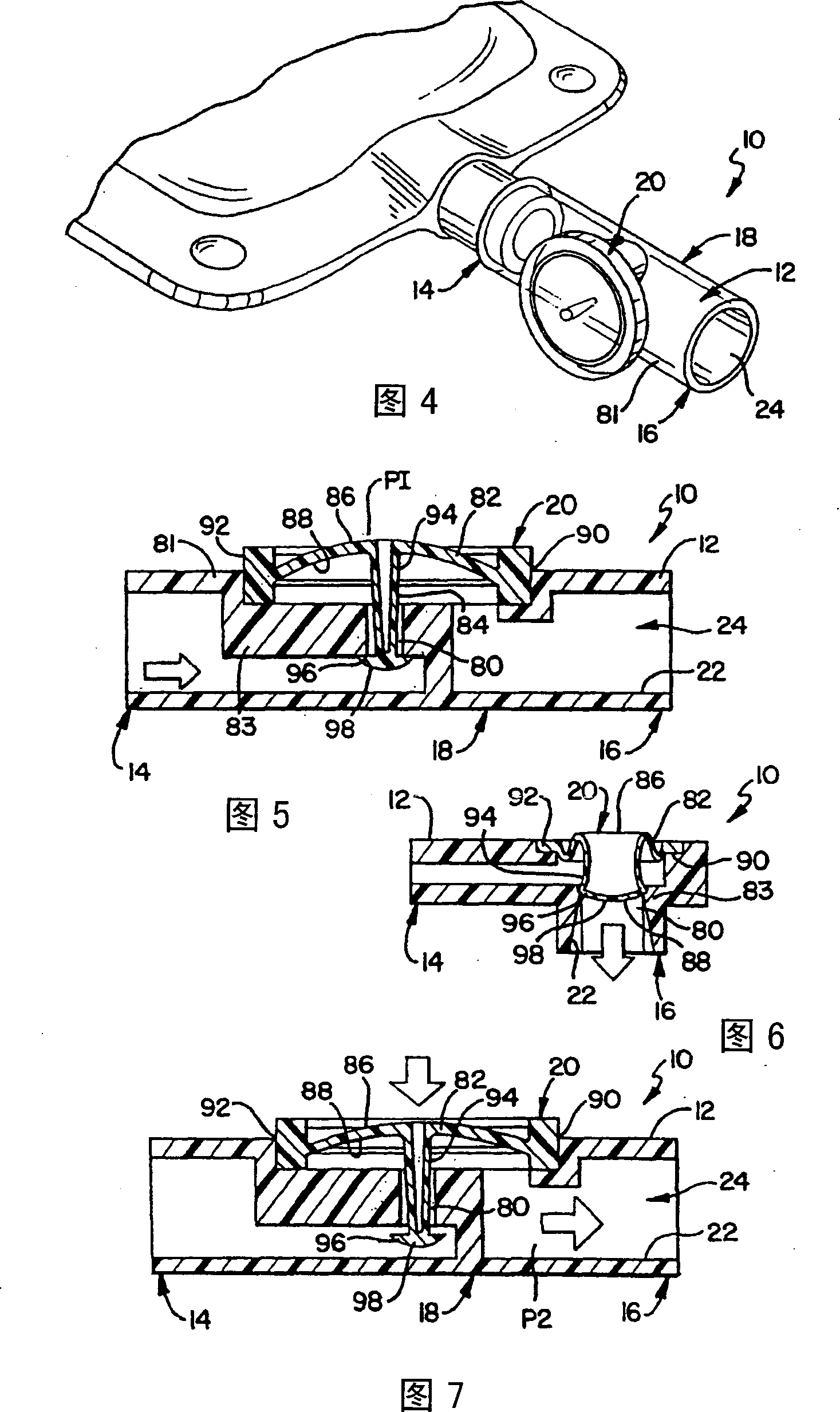

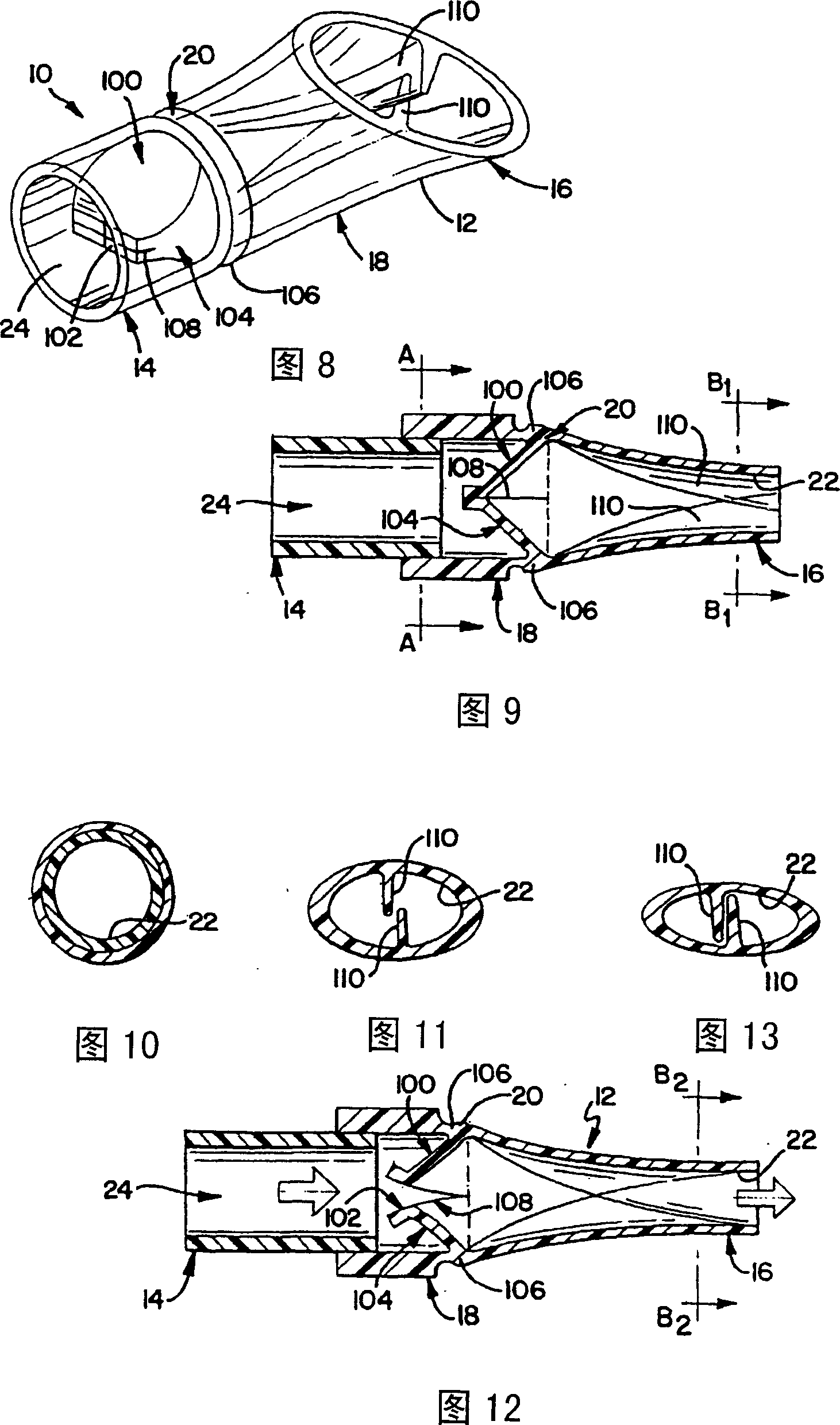

[0042] While the invention is capable of embodiments in many different forms, which are shown in the drawings and will be described in detail, the preferred embodiments of the invention, and an understanding of the disclosure, serve as illustrations of the principles of the invention rather than as It is intended to limit the invention in its broader aspects to the illustrated embodiments.

[0043] Referring now initially to Figures 1-26, a vacuum demand valve of the present invention is disclosed, generally indicated at 10 throughout. In a preferred embodiment, valve 10 may be implemented in a tubular structure and may be referred to as tube 10 . In one embodiment, the valve or tube 10 may be a medical tube 10 generally including an elongated sidewall 12 , a proximal end 14 , a distal end 16 , an intermediate section 18 and a valve member 20 . Tube 10 is generally considered to be the housing of the valve. The elongate side wall 12 has an inner wall 22 that defines a channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com