Process for detecting sheet steel product cross-sectional outline and shape

A technology of cross-section profile and detection method, which is applied to length measuring devices, metal processing equipment, metal rolling, etc., can solve the problems of inability to obtain point thickness values, time-consuming and labor-intensive, low work efficiency, etc., and achieves low cost and simple instrument structure. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

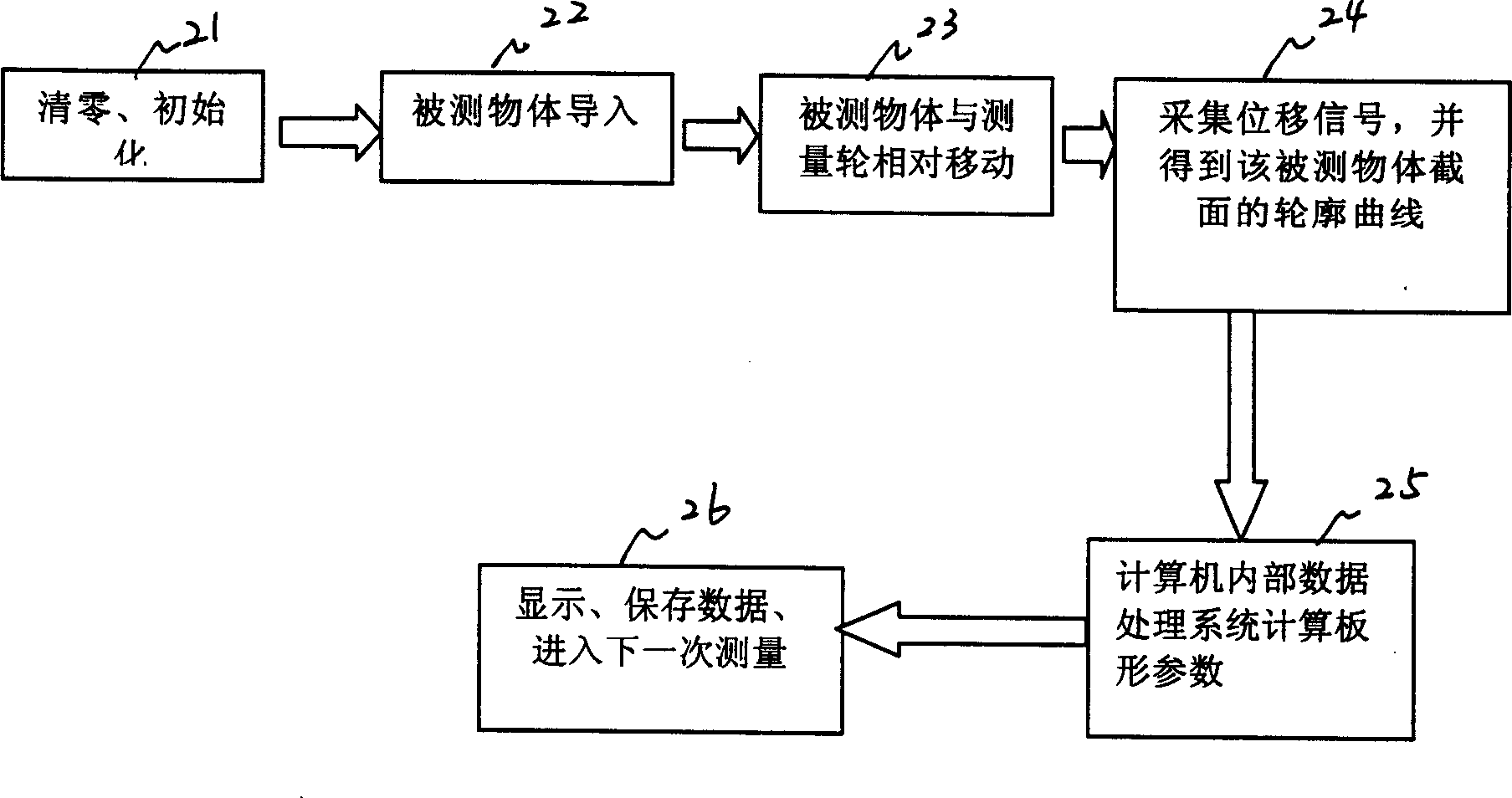

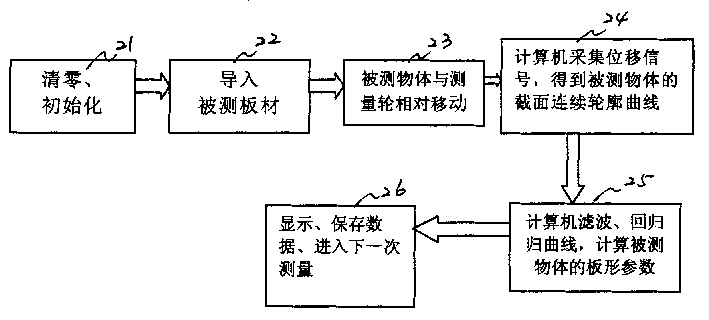

[0019] based on the following Figure 1 ~ Figure 2 , illustrating a preferred embodiment of the present invention.

[0020] Such as figure 1 As shown, the measured plate 3 advances along the upper and lower symmetrical measuring wheels 11, 11', and the measuring wheels 11, 11' receive the plate thickness change of the section of the measured plate 3, and make up and down displacements, thus driving the transmission The rod 12 and the transmission rod 12 are vertically inserted in the guide linear bearing 13 to form a mechanical transmission structure. The guide linear bearing 13 is displaced up and down; a measurement reference plate 14 is set above the guide linear bearing 13, and the measurement reference plate The horizontal plane where 14 is located is perpendicular to the upper and lower displacement movement planes of the guide linear bearing 13, and the guide linear bearing 13 drives the measurement reference plate 14 to move up and down, and a high-precision eddy curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com