Rolling drum type washing machine

一种滚筒式洗衣机、滚筒的技术,应用在洗衣机领域,能够解决滚筒前端面安装蓄水箱、不能有效补偿偏心载荷等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

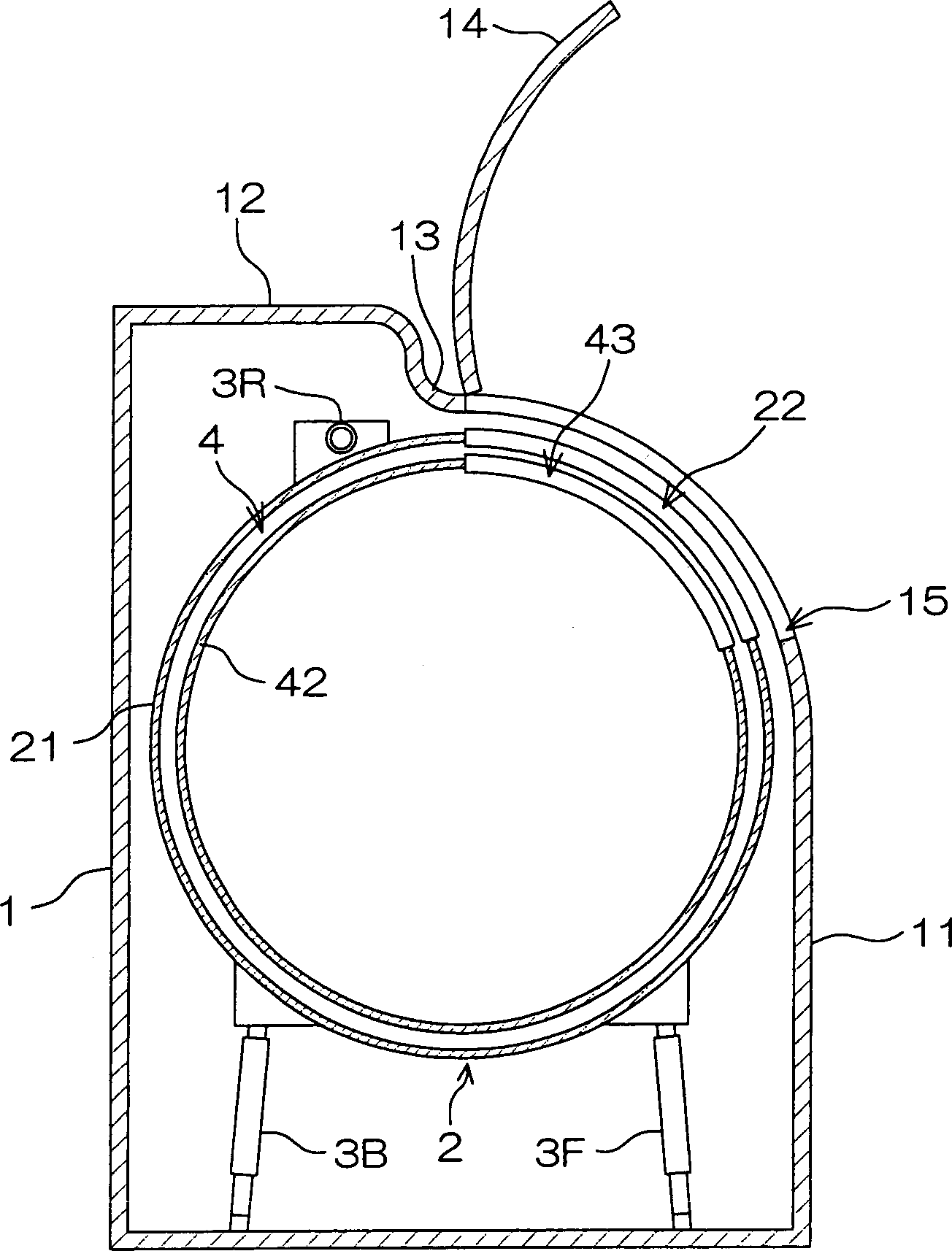

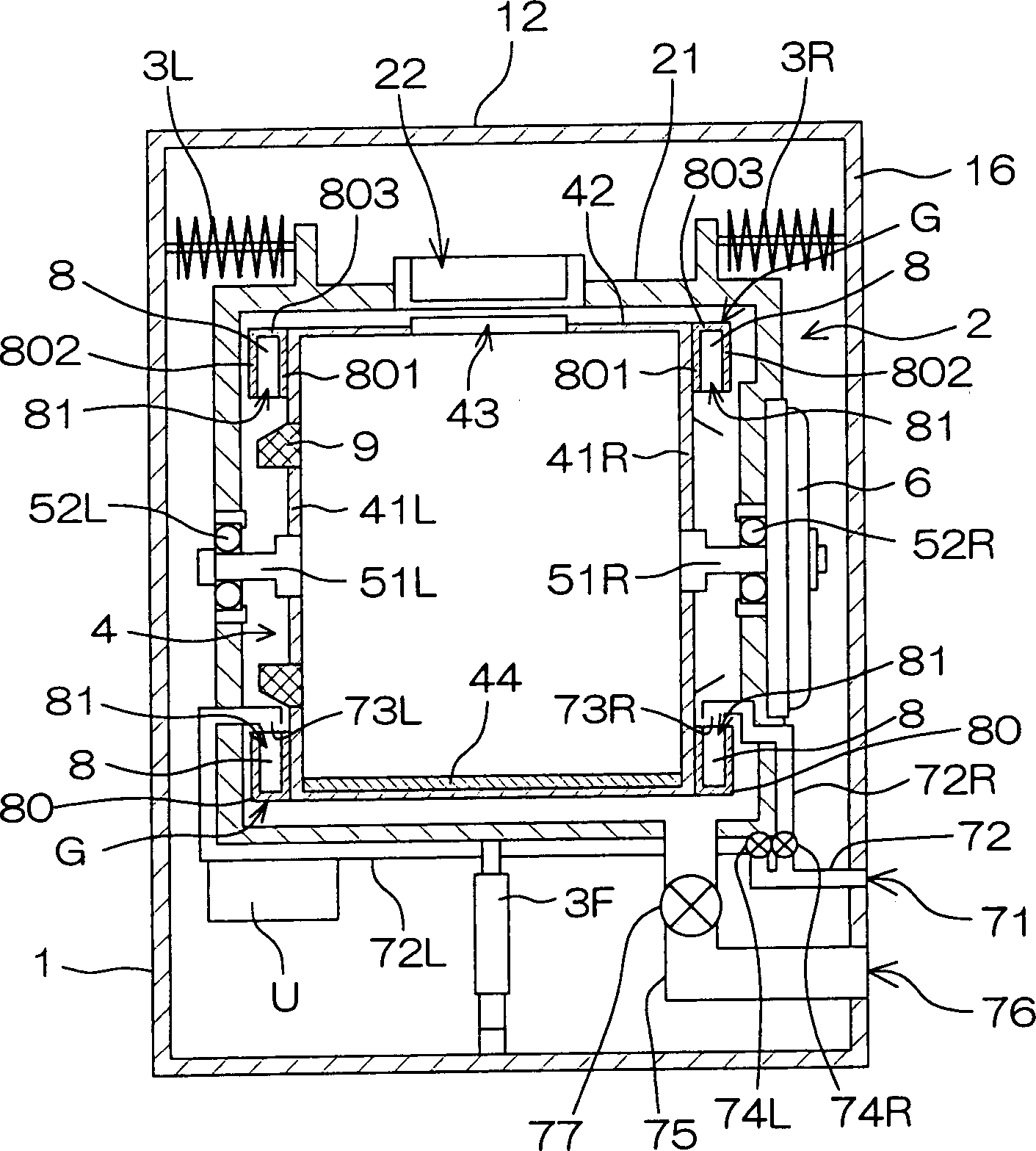

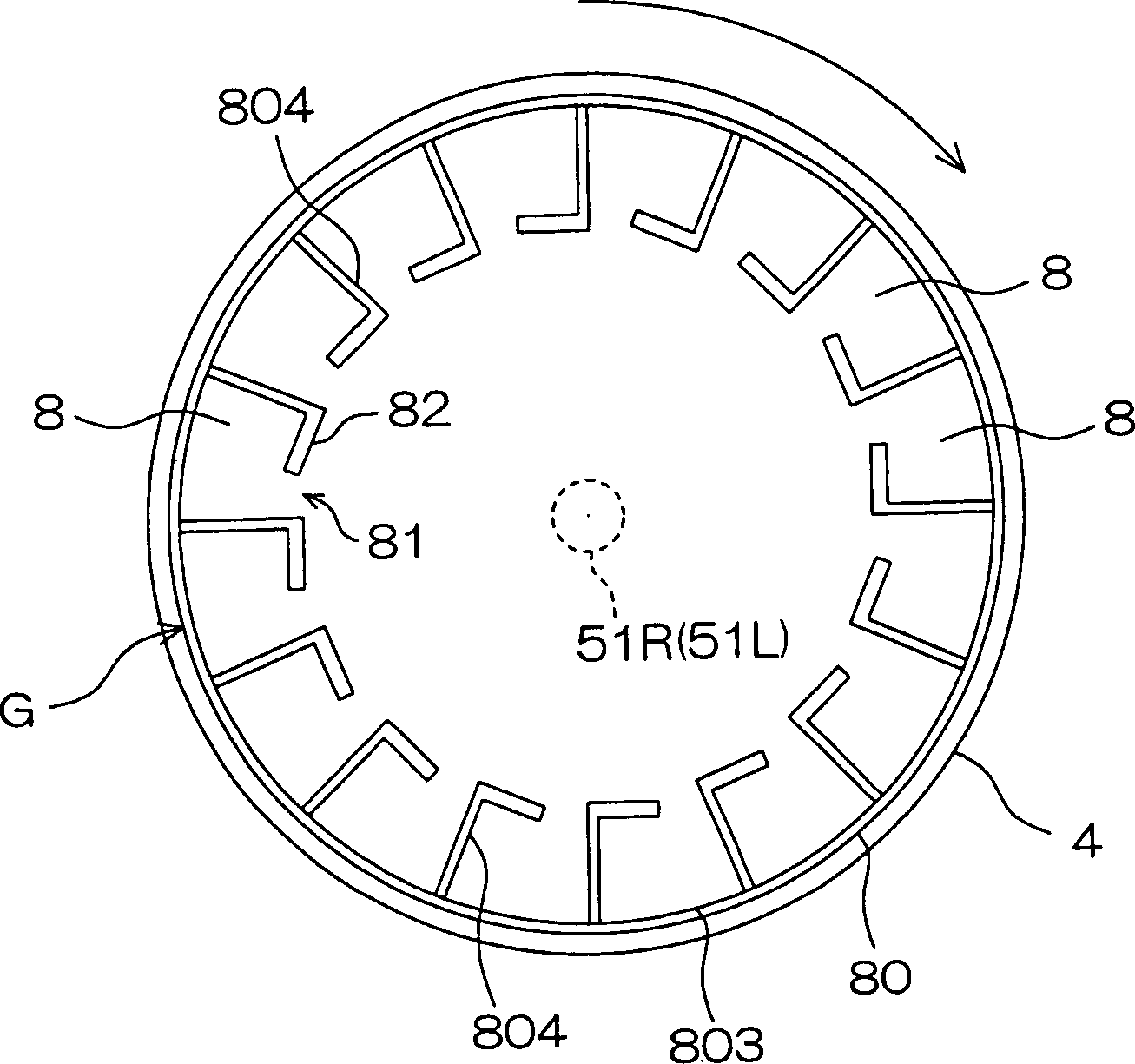

[0027] figure 1 and figure 2 is a longitudinal sectional view of the overall structure of the drum-type washing machine in Embodiment 1 of the present invention, figure 1 A section taken along a vertical plane in the front-back direction is shown. figure 2 A cross section taken along a vertical plane in the left-right direction is shown.

[0028] The casing 1 constituting the appearance of the front-loading washing machine is made in a size that can be installed on the base of the washing machine. The ground setting height of the washing machine (the height from the ground to the top of the casing 1) is set to reach near the height of the user's waist.

[0029] The casing 1 is provided with a hollow cylindrical outer tank 2 with its end facing left and right. The outer tank 2 is supported by a pair of baffles 3F, 3B and a pair of coil springs 3L, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com