Accurate control valve

A control valve and precision technology, applied in the direction of valve device, function valve type, fluid distribution valve, etc., can solve the problem that the valve has only switch function, no measurement function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

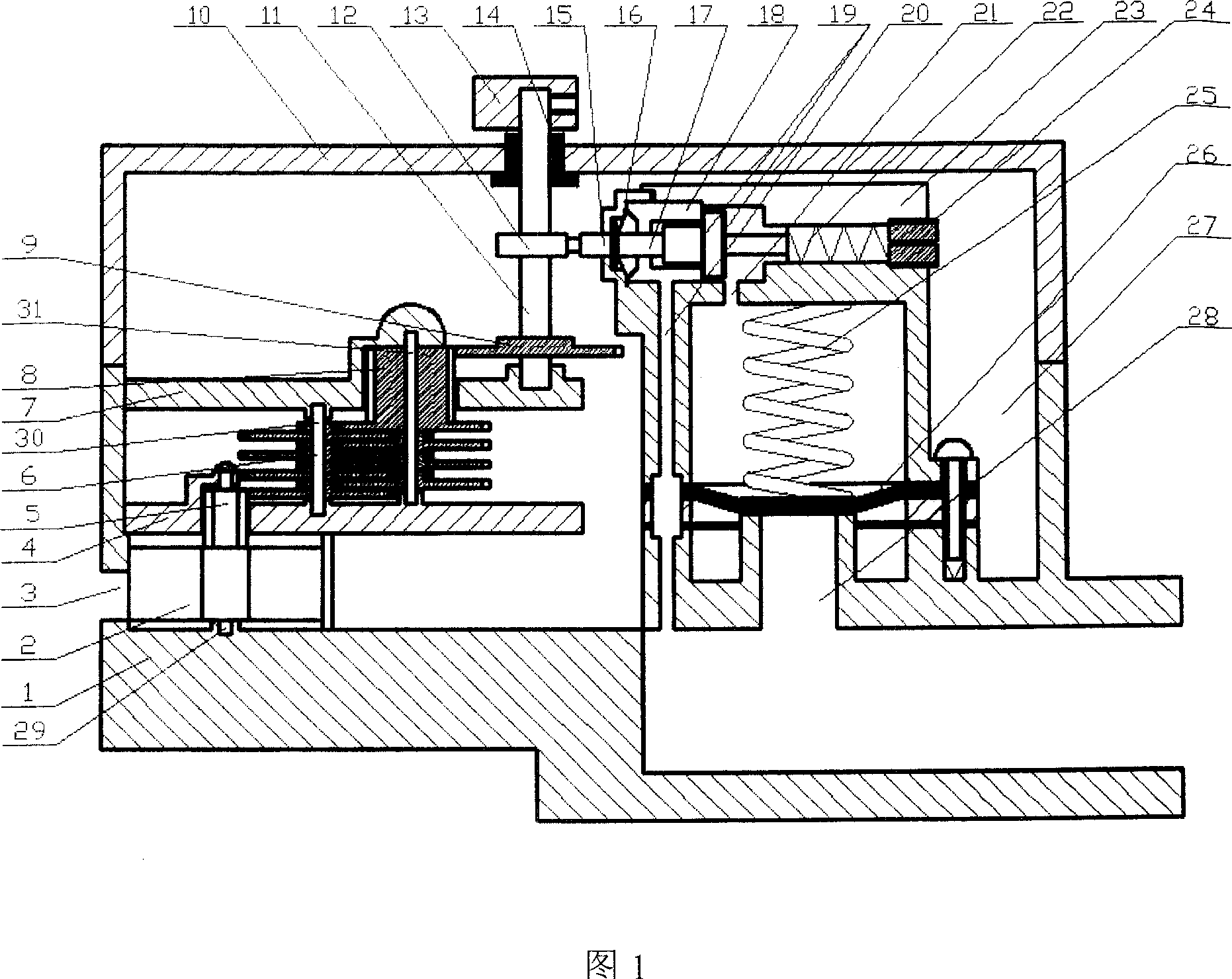

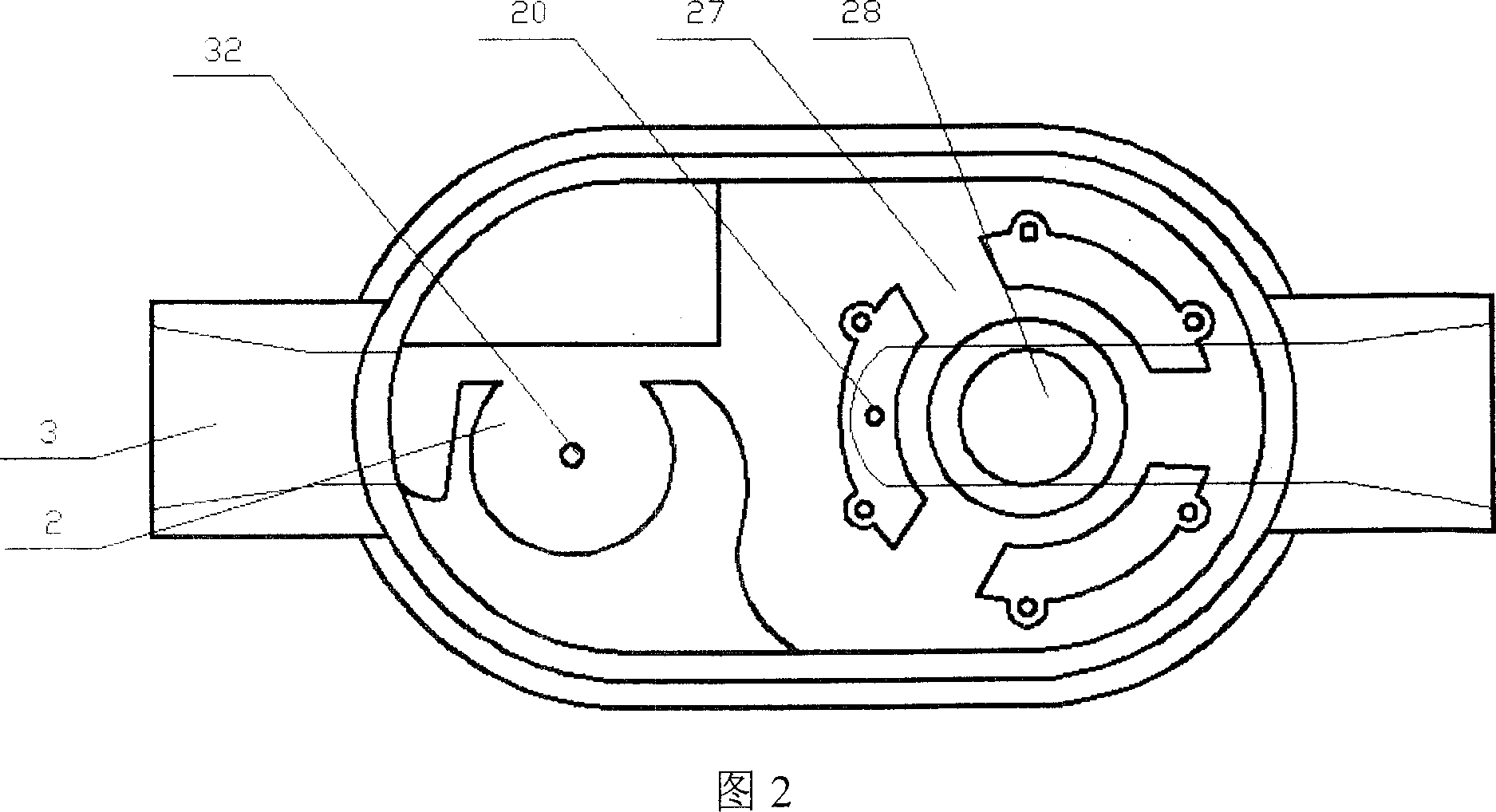

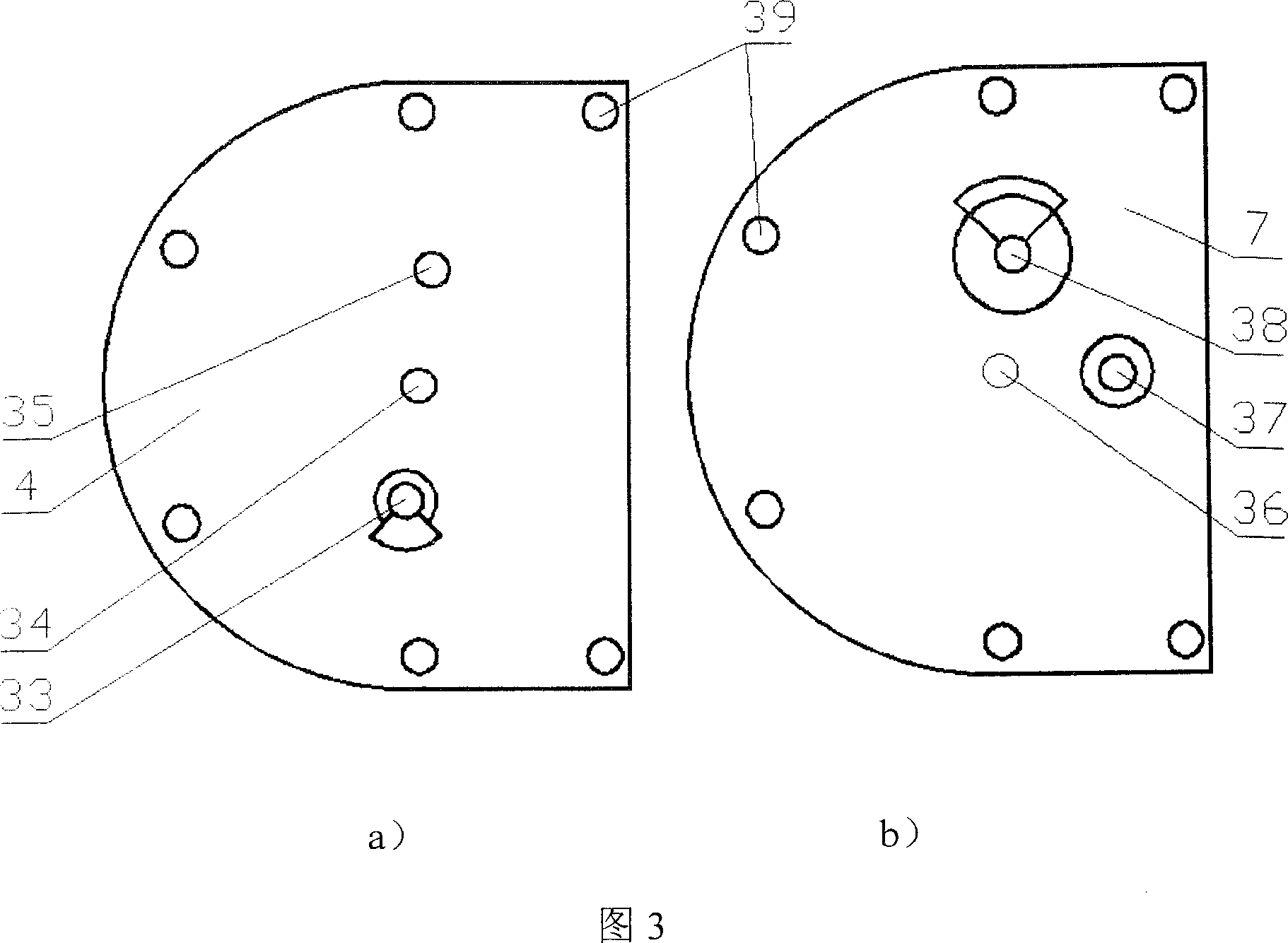

[0018] Please refer to accompanying drawings 1, 2, 3, 4, 5, 6, 7, 8, 9, the structure of the precision control valve of the present invention includes: a main body seat 1 and a main body cover 10, the figure of the main body seat 1 is shown in Fig. 2 A water inlet 3 is provided between the main body seat 1 and the main body cover 10, and an impeller 2 is arranged at the water inlet 3; the impeller 2 is fixed on the main body seat by the main body seat 1 and the first fixed tray 4 (Fig. 1, the impeller 2 is provided with a first gear 5, the first gear 5 and the impeller 2 are fixed as a whole, the impeller 2 and the first gear 5 can rotate around the impeller shaft 29; the first gear 5 and the first fixed tray 4 The reduction gear set 6 meshes (Fig. 8, 9), the reduction gear set 6 is fixed by the first fixed pallet 4 and the second fixed pallet 7 (Fig. 3b) through the first gear shaft 30 and the second gear shaft 31, the reduction gear set 6 The second gear 8 is arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com