Multistage location sylinder

A technology for positioning cylinders and cylinder barrels, which is applied in the direction of fluid pressure actuating devices, etc., and can solve the problems of undetected oil cylinders, inability to accurately determine the position, and inability of gas to reach the precise position, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

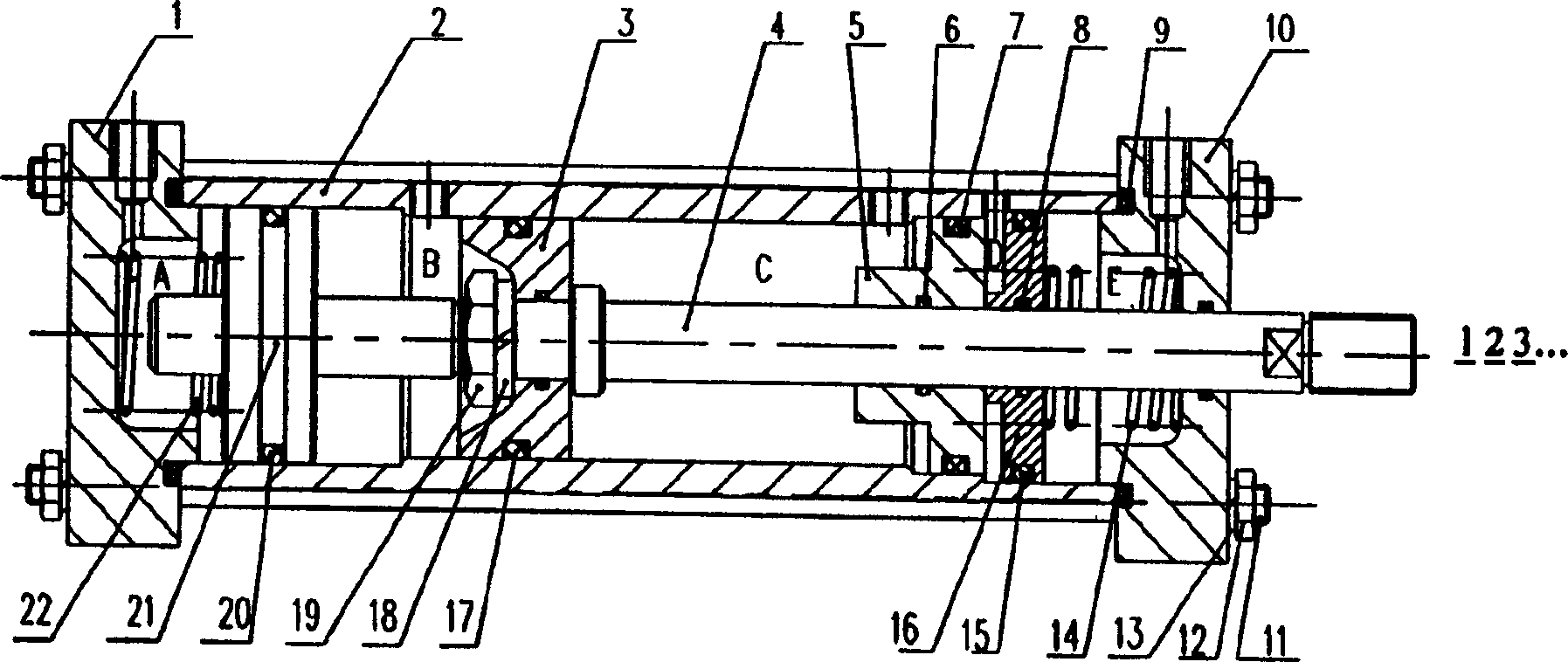

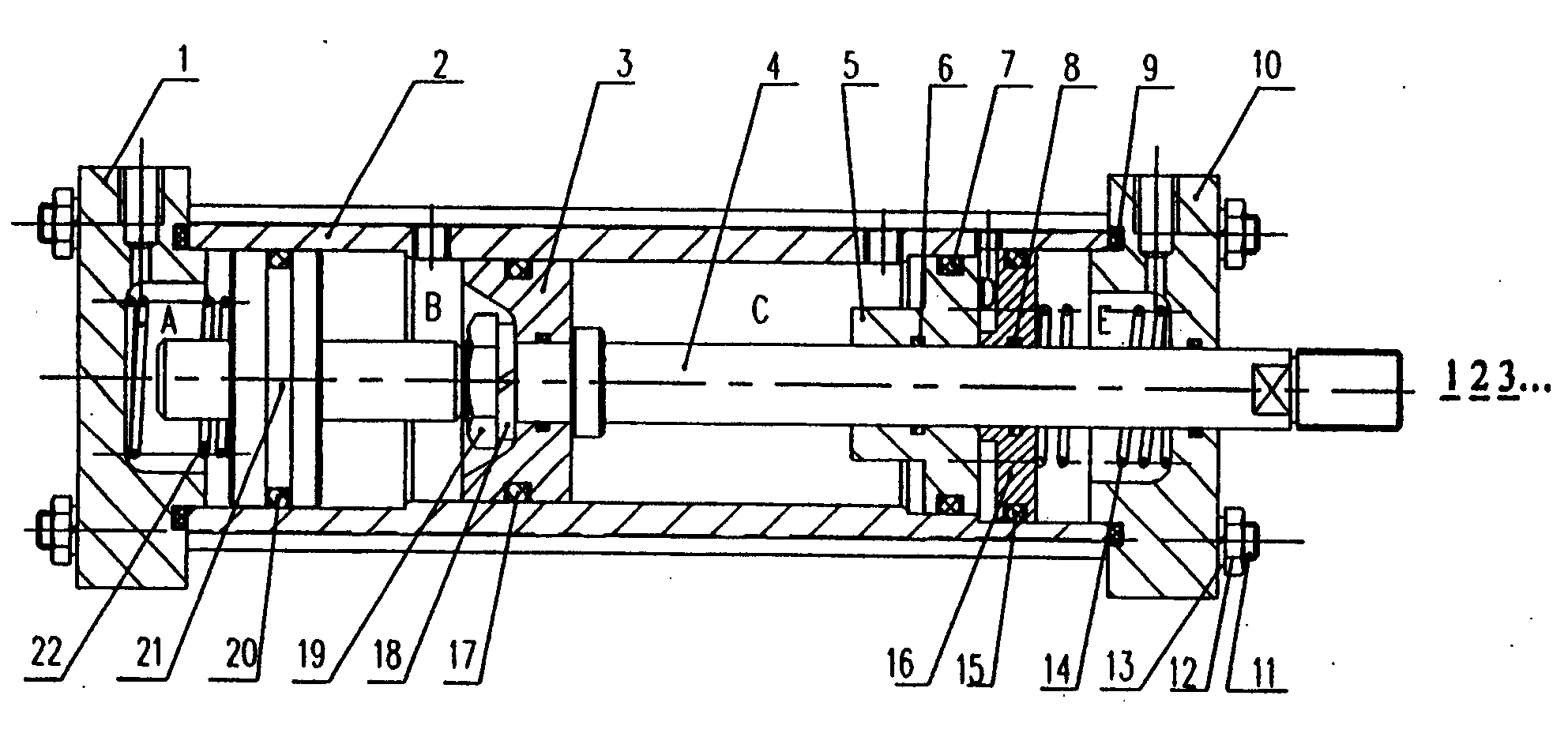

[0008] see figure 1 , the present invention is made up of following main components: left and right end caps 1,10, cylinder barrel 2, piston 3, piston rod 4, left retaining ring 21, right retaining ring 5,16, sealing ring 6,7,8,9,15 , 17, 20, etc., left and right springs 14, 22, threaded rod 11, nuts 12, 19, gaskets 13, 18, etc.

[0009] When chamber C takes in air (oil) and other chambers exhaust (oil), the air (oil) cylinder is at position 1; when chambers A and C take in air (oil) and the rest exhaust (oil), air (oil) Cylinder extends to position 2; when chambers B and D take in air (oil) and the rest exhaust (oil), air (oil) cylinders extend to position 3; and so on, if you choose different chambers for air (oil) And exhaust (oil), then can push out different positions, obviously, it can satisfy the demand to multi-stage expansion and contractio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com