Shoe tree of multi-component

A multi-component, shoe last technology, applied in shoe lasts, footwear, applications, etc., to avoid work delays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

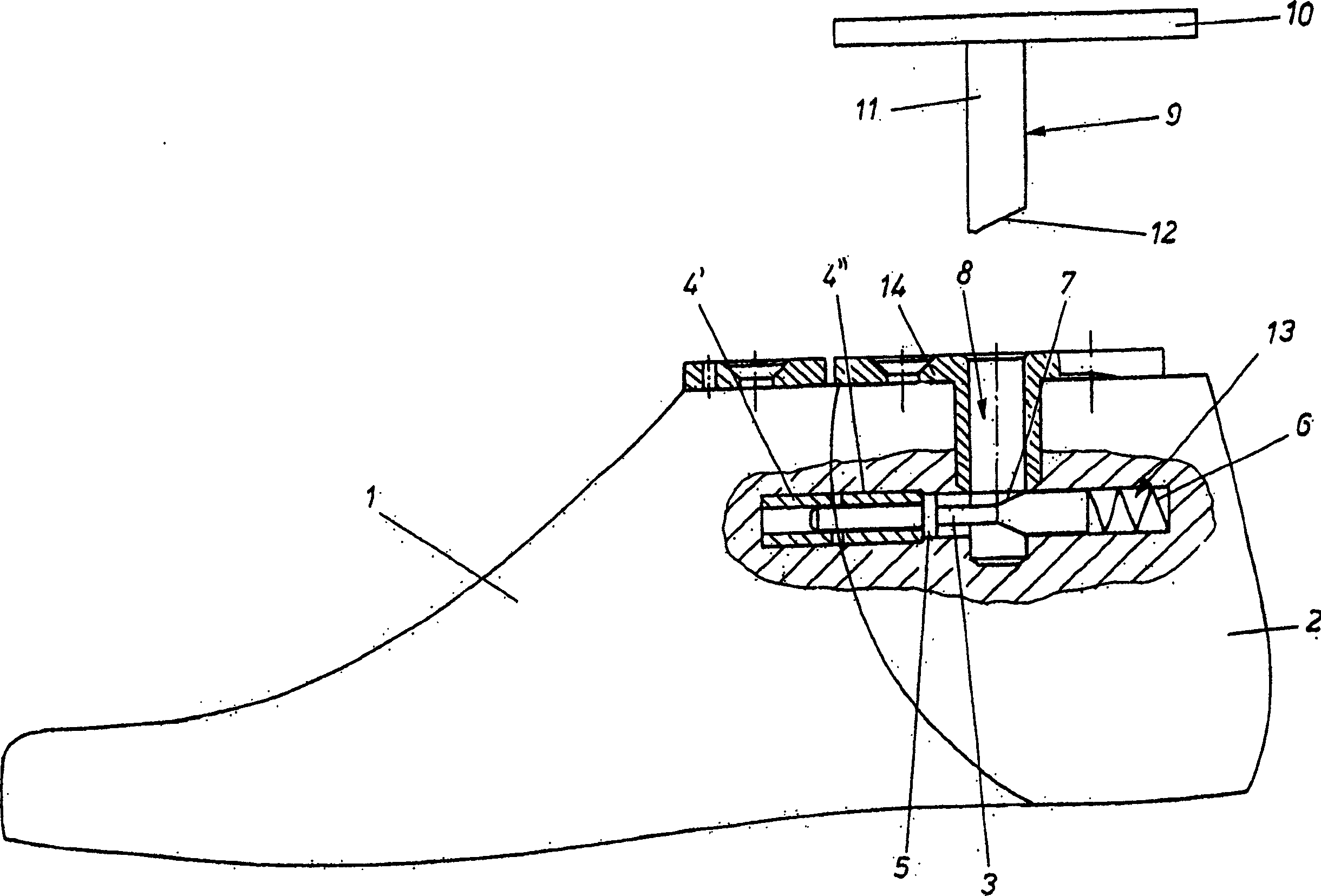

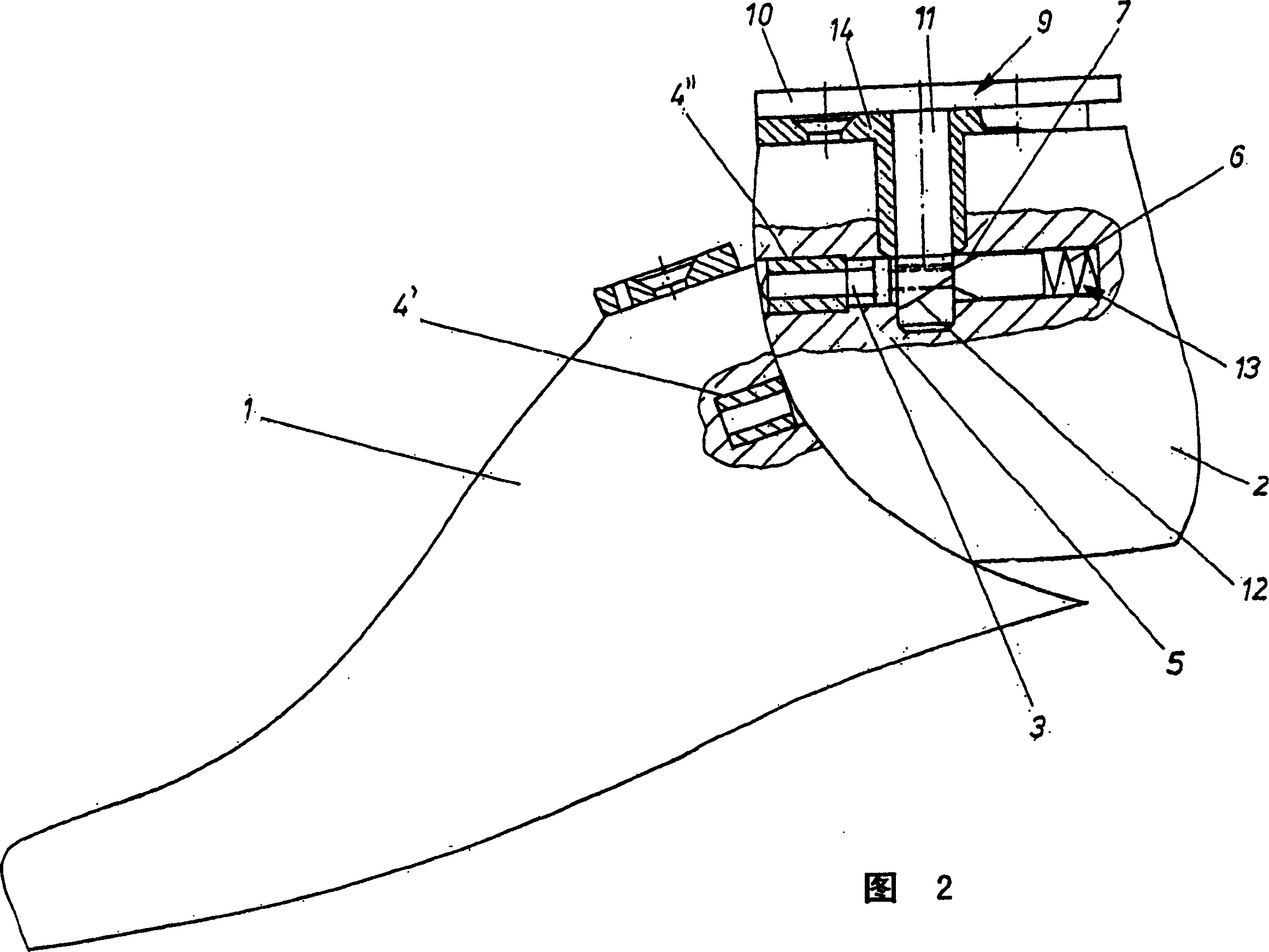

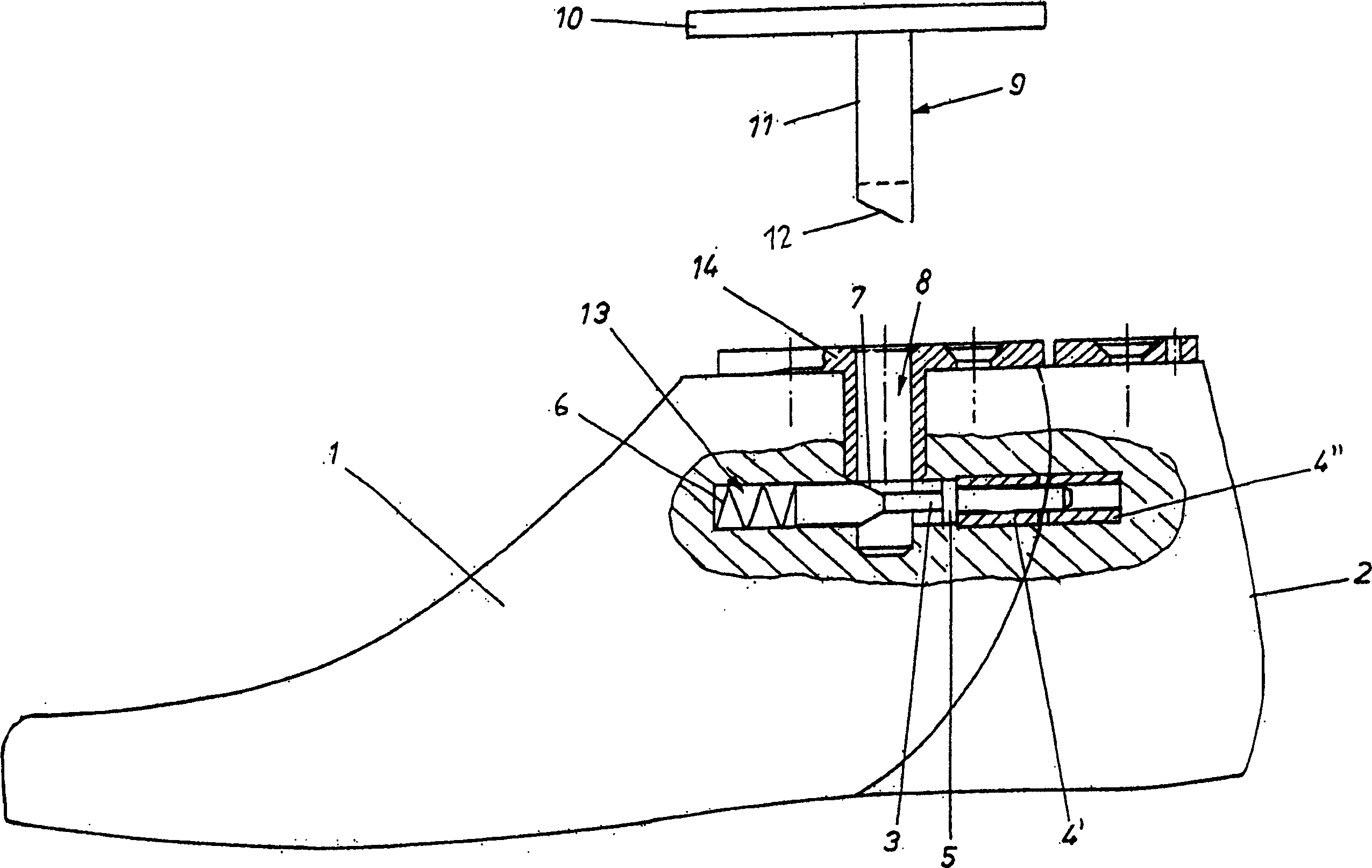

[0028] The shoe last in the embodiment is made up of two parts 1, 2, and they can move relatively. exist figure 1 and 2 and Figure 5 and 6 examples, part 1 can be obtained from figure 1 and 5 The closed configuration of the last shown in Fig. 2 and 6 is moved into the open configuration shown in Figs. This is part 1 of the last.

[0029] exist image 3 and 4 In the shoe last, it refers to the part 2 of the shoe last, which can be deflected from the image 3 The closed structure of the last shown in the move to Figure 4 in the open structure shown in .

[0030] The two components 1, 2 are combined together through a connecting mechanism not shown in the figure.

[0031] In order to make parts 1 and 2 of the shoe last in figure 1 , 3 The closed working position of the shoe last shown in 5 is relatively fixed, and a fixing mechanism is provided. The fastening means comprises, as a stop, a pin 3 which is situated in a receiving groove 13 and which is seated in sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com