Degradable plastic granulator with adjustable feeding amount

A technology for degrading plastics and granulators, which is applied in the direction of plastic recycling and recycling technology, and can solve the problems of inconvenient feeding, watertightness, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail with reference to the accompanying drawings in the embodiments of the present invention.

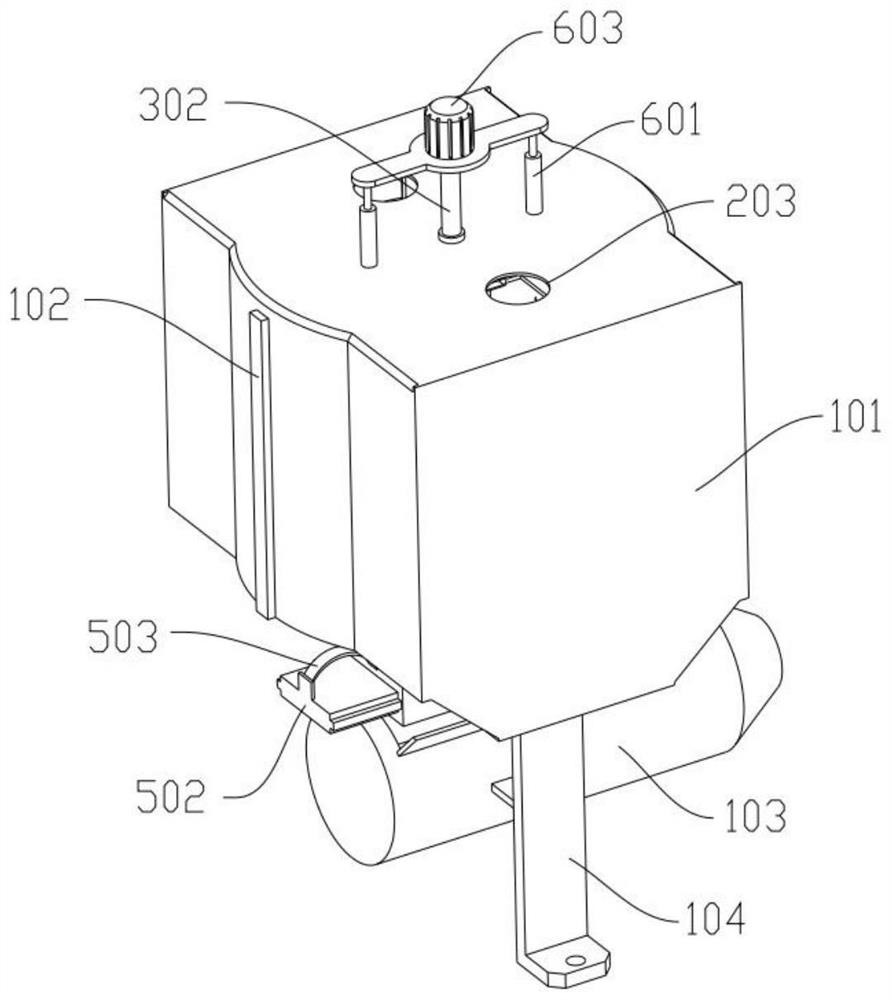

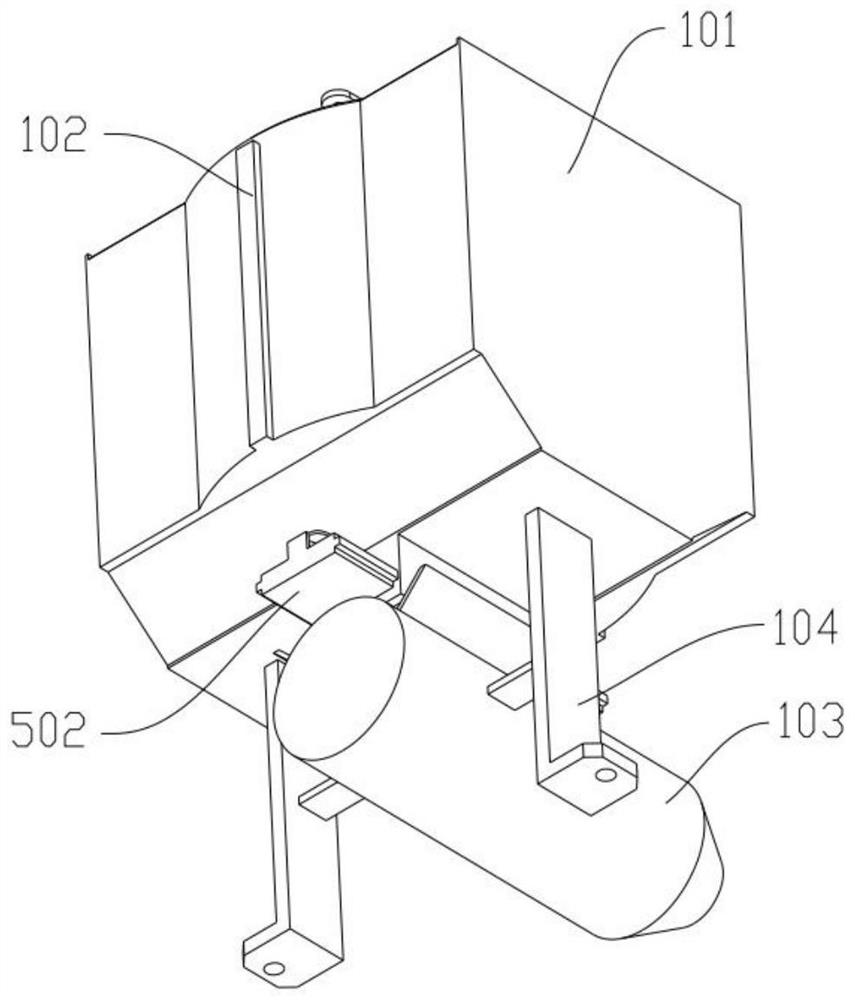

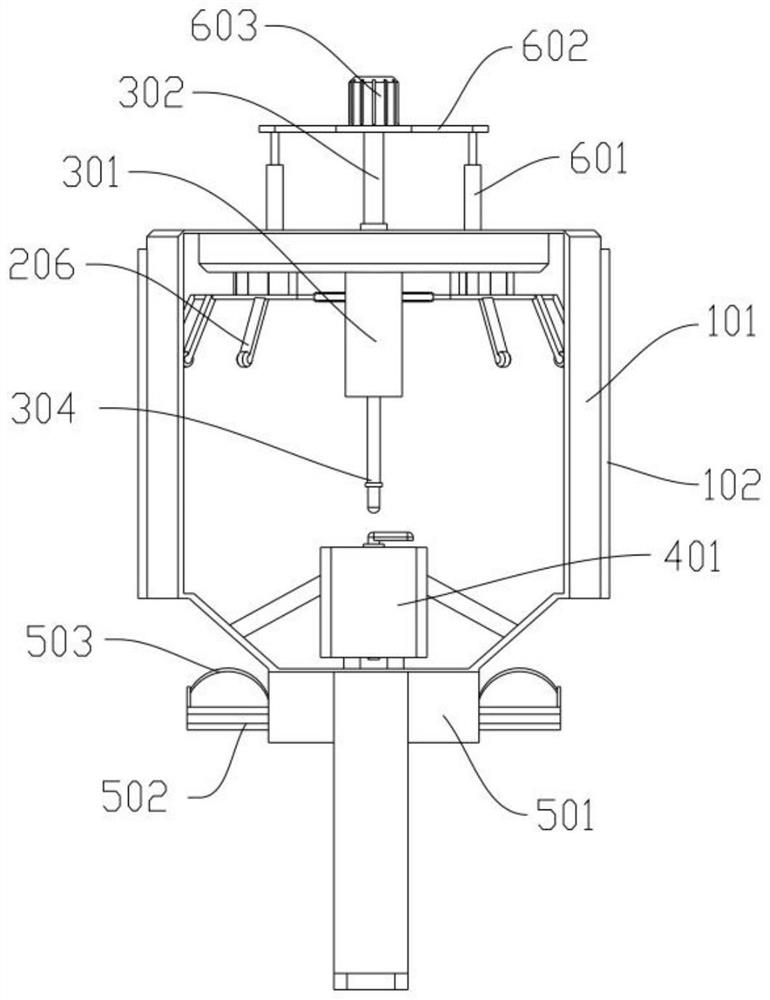

[0025] Referring to 1-10, a schematic diagram of an embodiment that can adjust the feeding amount according to actual needs in the present invention is shown, and further,

[0026] The device includes a hot-melt box 101, two electric heating wires 102 are fixedly connected to the hot-melt box 101 by bolts, a discharge port 501 is opened at the bottom of the hot-melt box 101, and two stoppers 502 are slidably connected in the discharge port 501. The discharge port 501 is provided with a rectangular groove horizontally, and two blocks 502 cooperate with the rectangular groove to slide in the discharge port 501. The lower end of the hot melt box 101 is welded and fixedly connected with two legs 104, and the middle of the two legs 104 is welded. The main body 103 of the granulator is fixedly connected, the discharge port 501 is communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com