Magnetic type wire fixing device

A wire-fixing and magnetic-suction technology, which is applied to electrical components and other directions, can solve the problems of not being able to fix the cable, the tie is falling off, and the wiring is difficult, so as to achieve the effect of convenient wiring and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

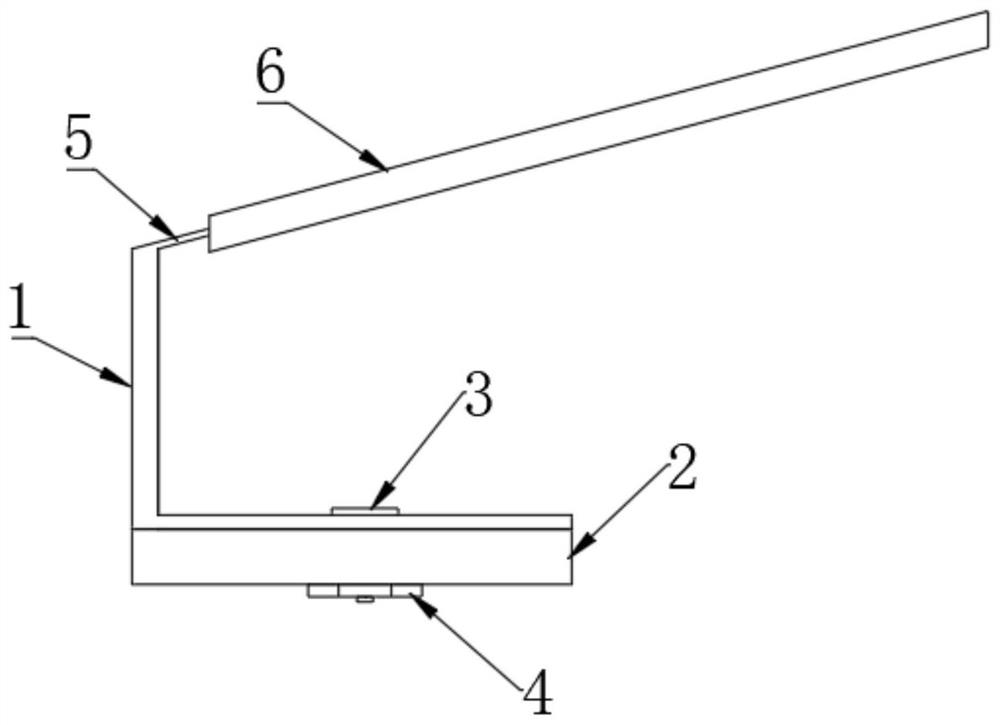

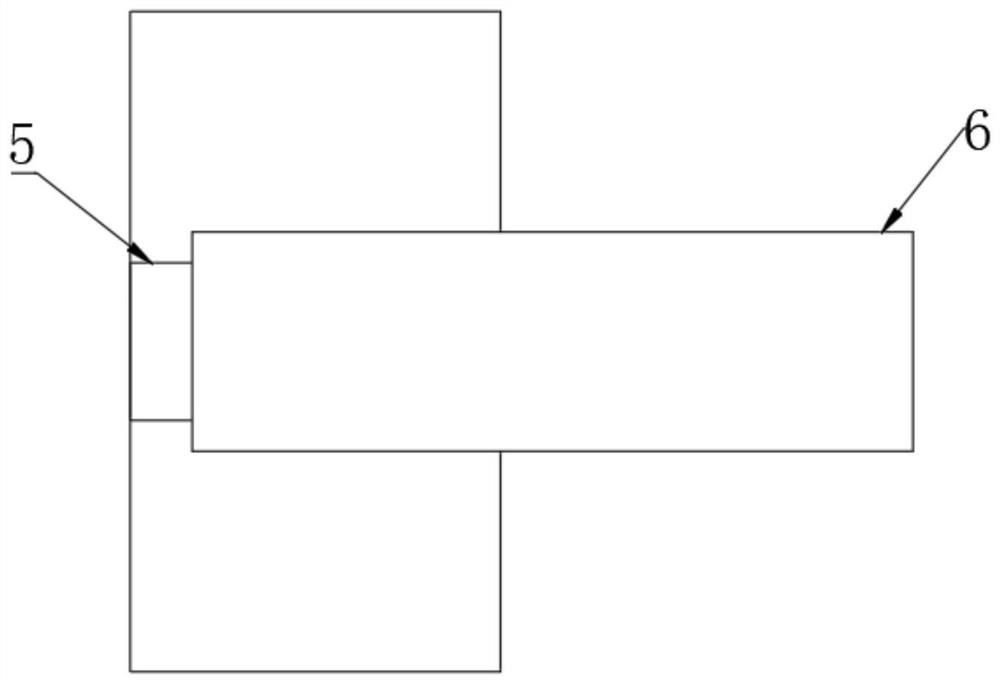

[0019] A magnetic wire fixer, comprising a wire fixer body 1, a magnet 2, a metal shrapnel, a screw 3, and a nut 4, is characterized in that: a magnet 2 is adsorbed on the outer surface of the fixer body 1, and the magnet 2 is A square magnet, the wire fixer body 1 and the square magnet 2 are both provided with threaded holes, the square magnet 2 and the metal shrapnel are fixed with screws 3 and nuts 5, and the metal shrapnel has a retaining spring 5, which can The cable is fixed in the middle of the clip, and the outer wall of the clip spring 5 is sleeved with a plastic sheath 6 .

[0020] The mounting position of the nut 5 and the screw 4 is set at the lower end of the square magnet 2 .

[0021] During the specific implementation of the present invention,

[0022] The present invention uses the magnet 2 and the metal shrapnel 4 to make a magnetic wire fixing devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com