Novel manual mechanical pipettor

A manual mechanical and pipette technology, applied in the field of laboratory equipment, can solve the problems of only one calibration point, low recognition of numbers 0-9, and inability to meet high precision, achieving high cost performance and low precision requirements , small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

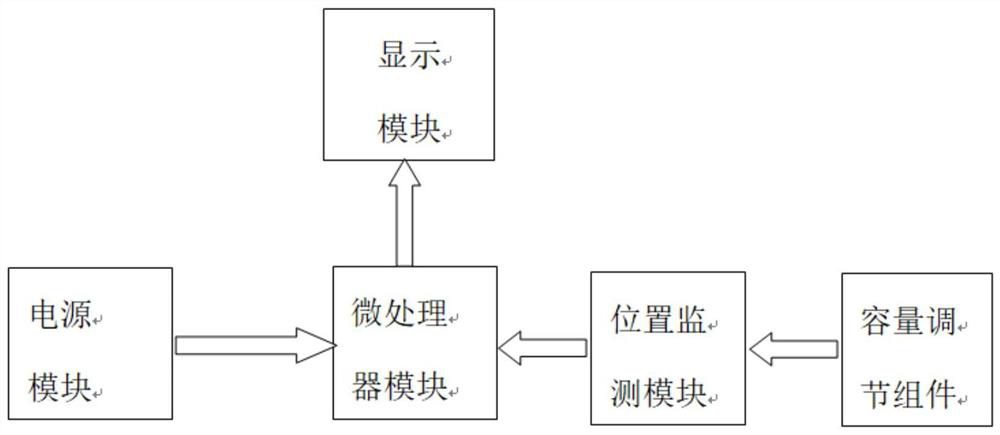

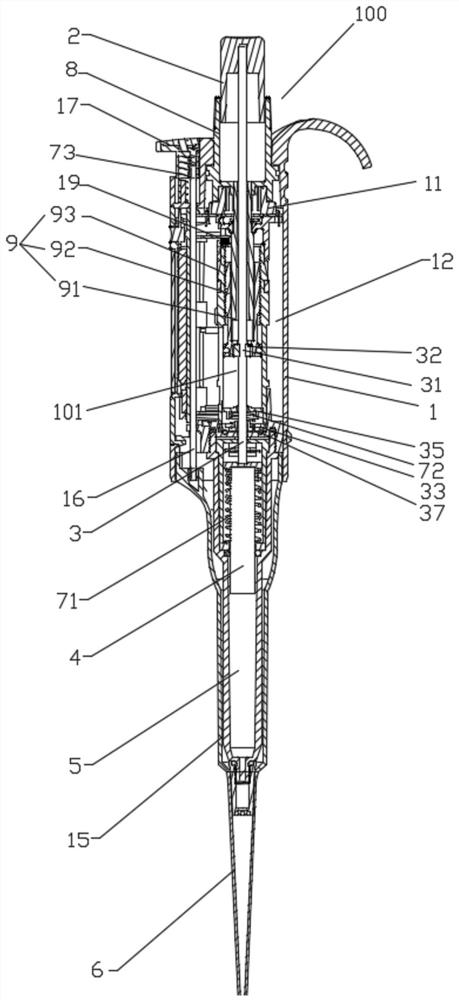

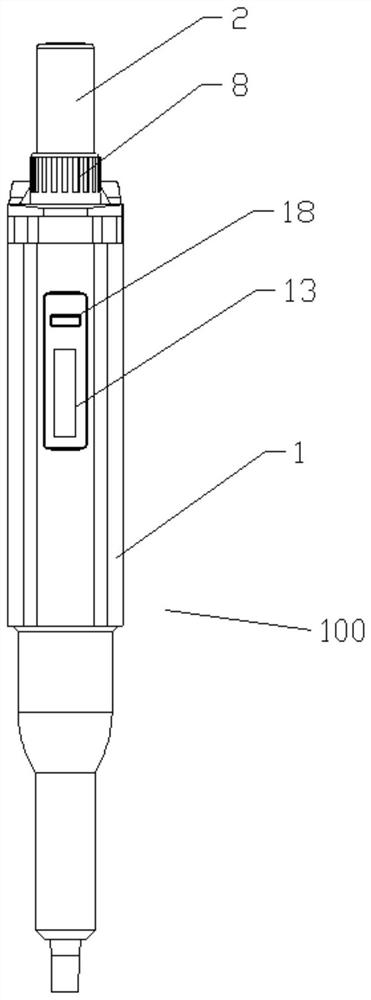

[0041] see figure 1 , A new type of manual mechanical pipette, which includes a pipette body, and a volume adjustment component, a position monitoring module, a microprocessor module, a conversion module, an information feedback module, and a power supply module arranged in the pipette body. ; the capacity adjustment assembly is used to adjust the stroke of the piston; the position monitoring module is used to obtain the stroke signal of the piston; the conversion module is used to convert the piston stroke signal obtained by the position monitoring module into an electronic signal; the The microprocessor module is used for data processing of the electronic signal to obtain the set capacity value; the information feedback module is used to feed back the set capacity value to the user, which includes visual feedback, auditory feedback and light feedback of indicator lights, etc. Specifically, such as a display screen, a buzzer, an indicator light, etc.; the power module is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com