Conveying device capable of automatically adjusting width of track

A transmission device and automatic adjustment technology, applied in transportation and packaging, thin material handling, sending objects, etc., can solve the problems of unable to automatically adjust the track width, printing information deviation, printing paper angle deviation, etc., to avoid printing The effects of information deviation, volume reduction, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

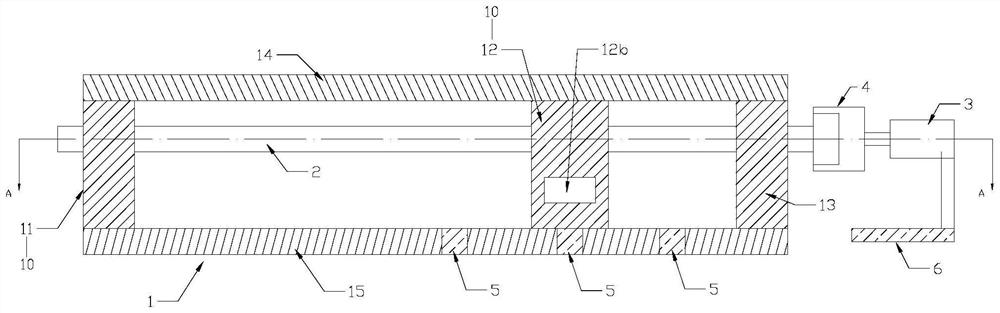

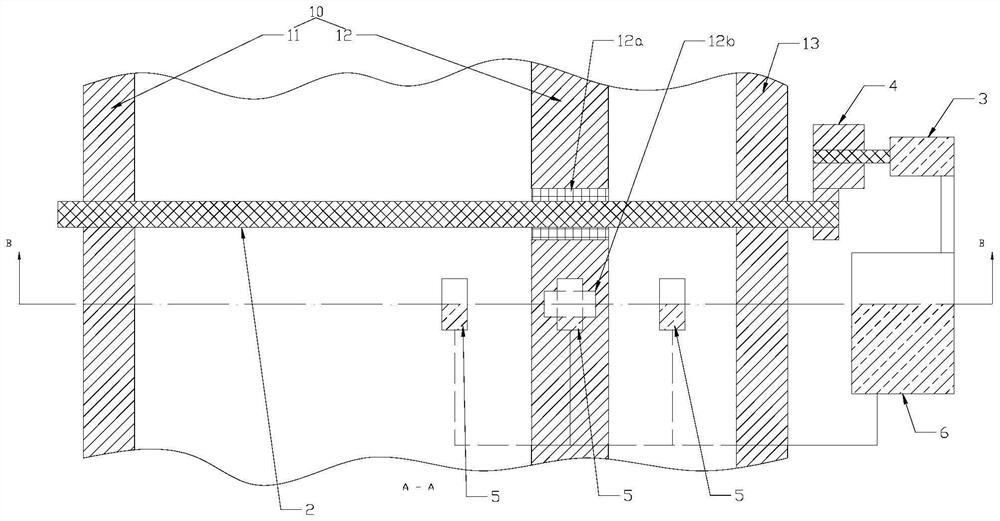

[0026] Embodiment: This embodiment provides a transmission device for automatically adjusting the width of a track, including a conveying part, an inductive detection part, and a control system. The conveying part includes a fixed side rail, a movable side rail and a drive assembly, the fixed side rail is fixedly arranged, the movable side rail is movably arranged relative to the fixed side rail, the fixed side rail and the movable side rail A conveying track for conveying printing paper is formed therebetween, the driving component is connected with the movable side track, and the driving component drives the movable side track to approach or move away from the fixed side track.

[0027] The sensing component includes a position indication element and a position detection element, the position indication element is provided on the movable side rail, and the position detection element is correspondingly provided on the fixed side rail; specifically, in this embodiment , the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com