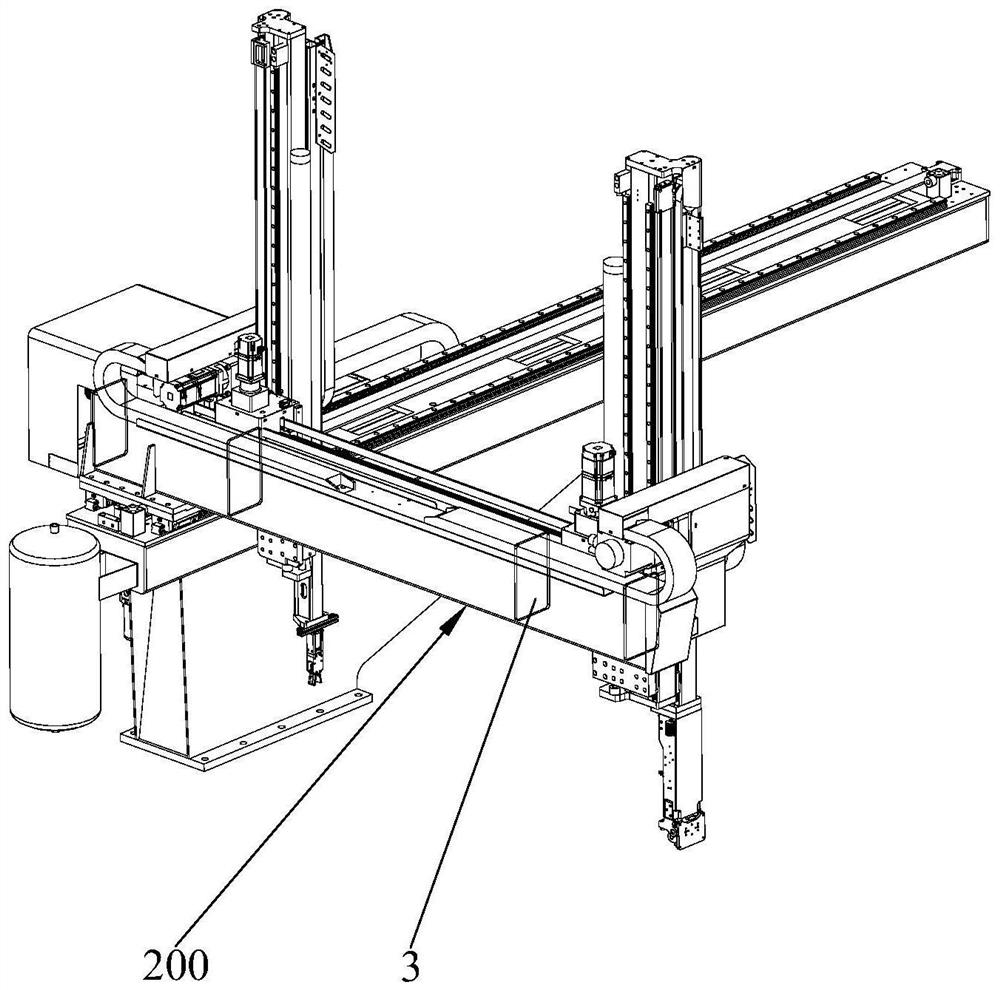

Manufacturing method of high-rigidity drawing arm and drawing arm manufactured by using same

A manufacturing method and high-rigidity technology, which can be used in claw arms, manufacturing tools, manipulators, etc., can solve the problems of increased transmission power, high energy consumption costs, and heavy weight of pulling arms, achieving low cost and reducing energy consumption costs. , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to describe the technical content and structural features of the present invention in detail, further description will be given below with reference to the embodiments and the accompanying drawings.

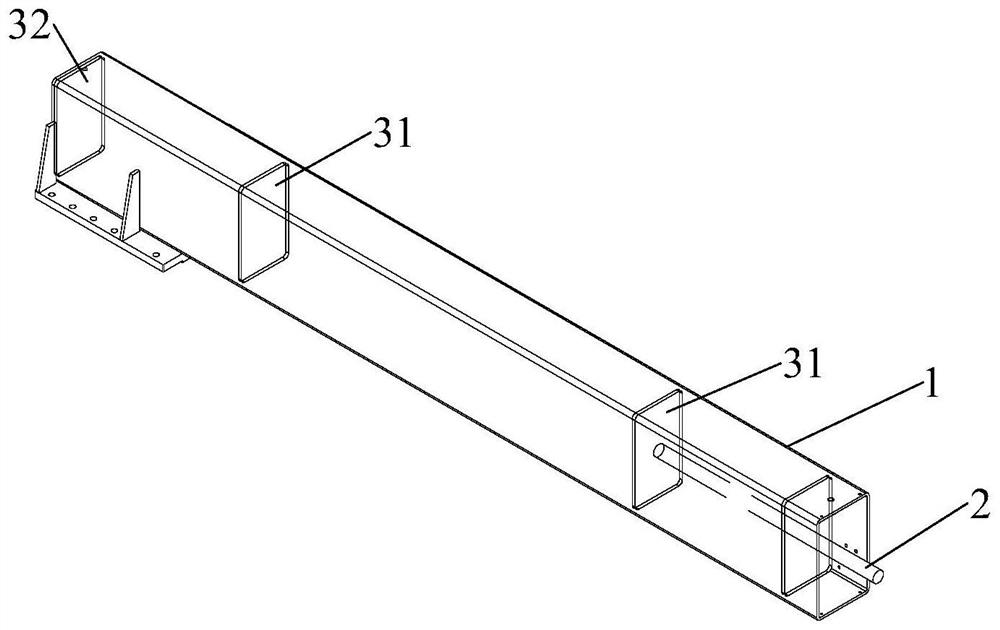

[0032] see Figure 2 to Figure 7 , the manufacturing method S100 of the high-rigidity pulling arm of the present invention comprises the following steps:

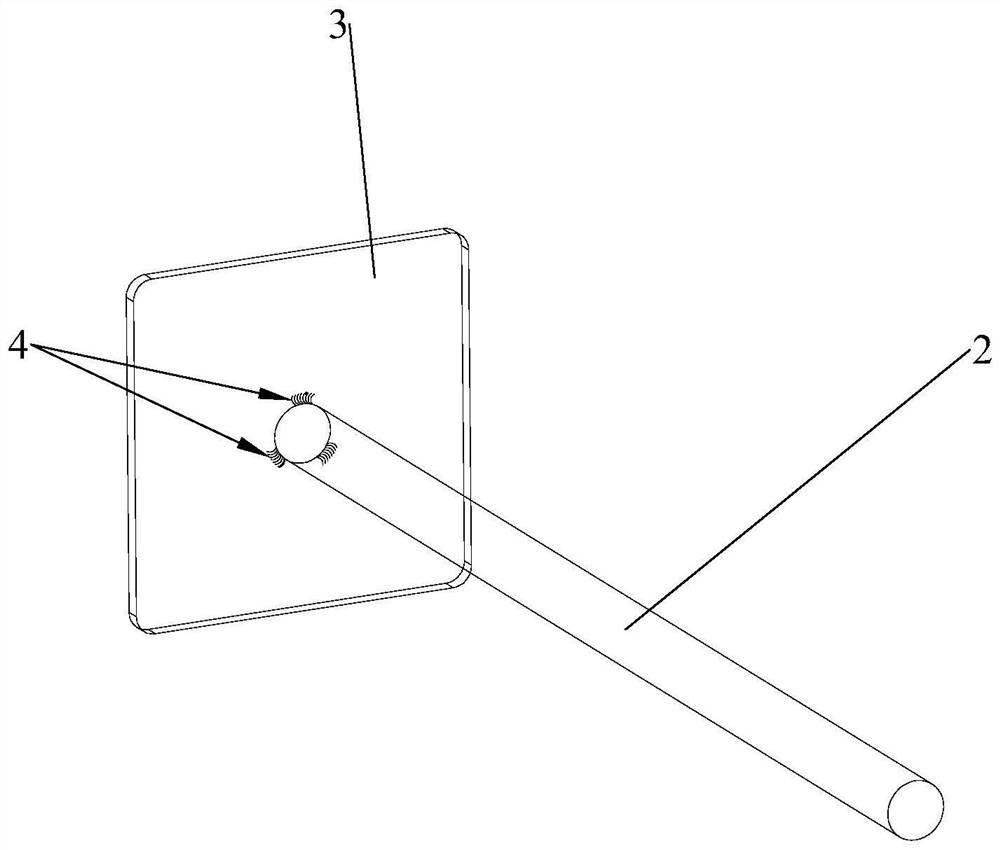

[0033] Step S01 : providing a steel bar 2 , a sealing plate 3 and a welding gun, and the welding gun welds the steel bar 2 on the surface of the sealing plate 3 by spot welding, so that the steel bar 2 is connected with the sealing plate 3 . Specifically, in this step, the number of welding points 4 between the steel rod 2 and the sealing plate 3 is 2-3, the welding points 4 are spaced apart around the circumference of the steel rod 2 , and the steel rod 2 is welded to the center of the sealing plate 3 Location. Spot welding is used for welding between the steel rod 2 and the sealing plate 3, so the subsequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com