Wiper arm

A wiper arm and wiper technology, applied in vehicle cleaning, vehicle maintenance, circuits, etc., can solve problems such as inability to ensure positioning and poor orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

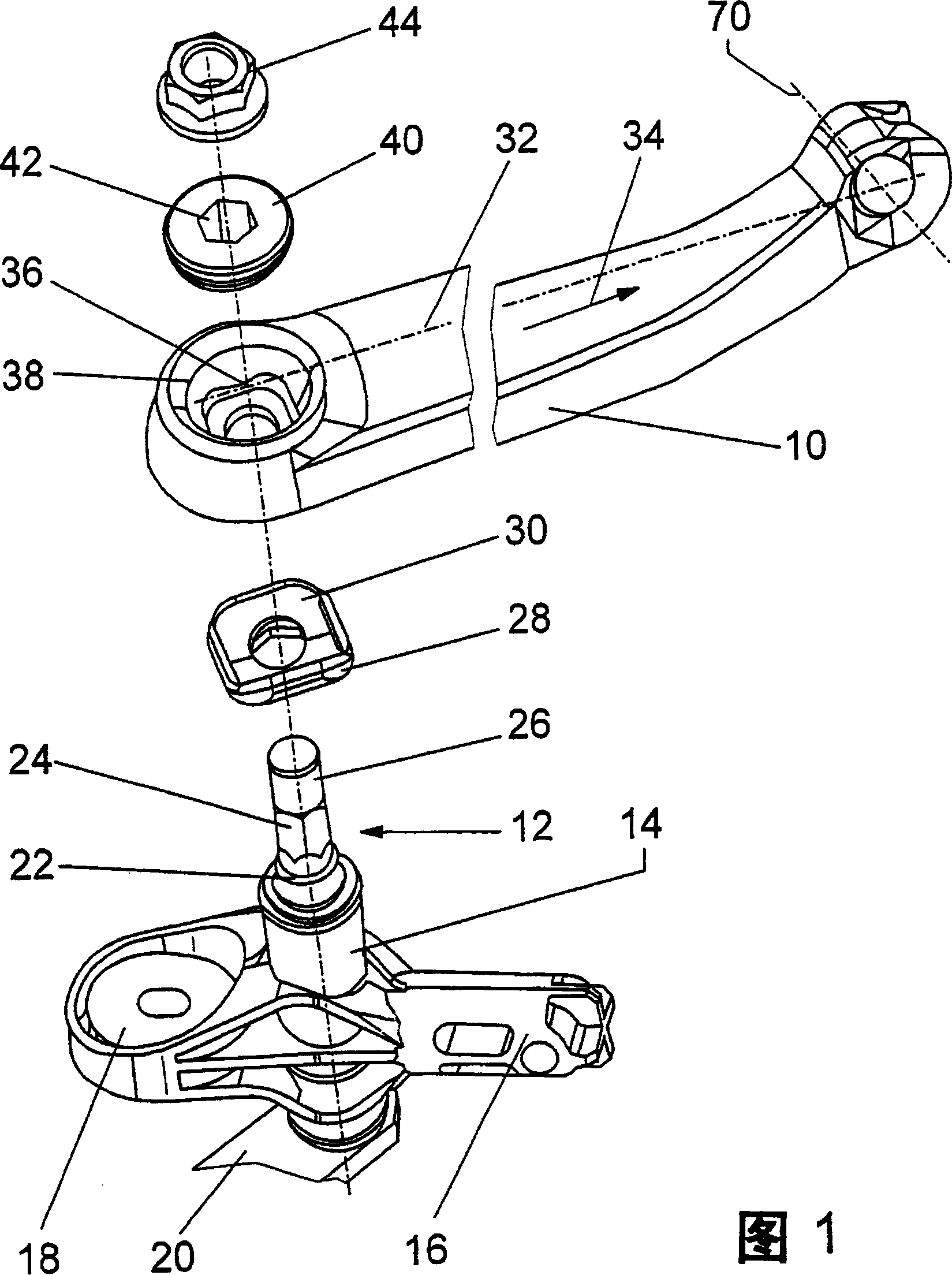

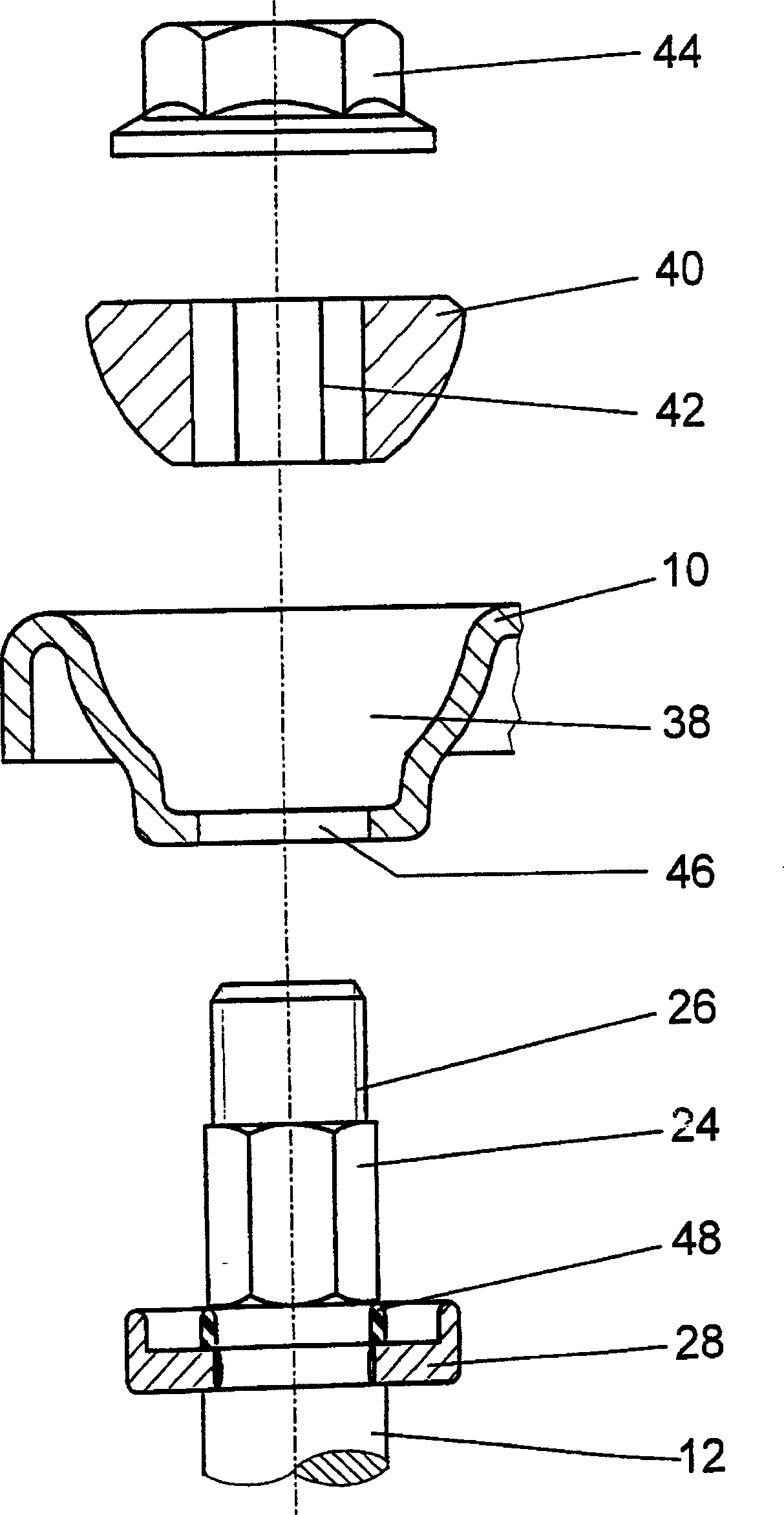

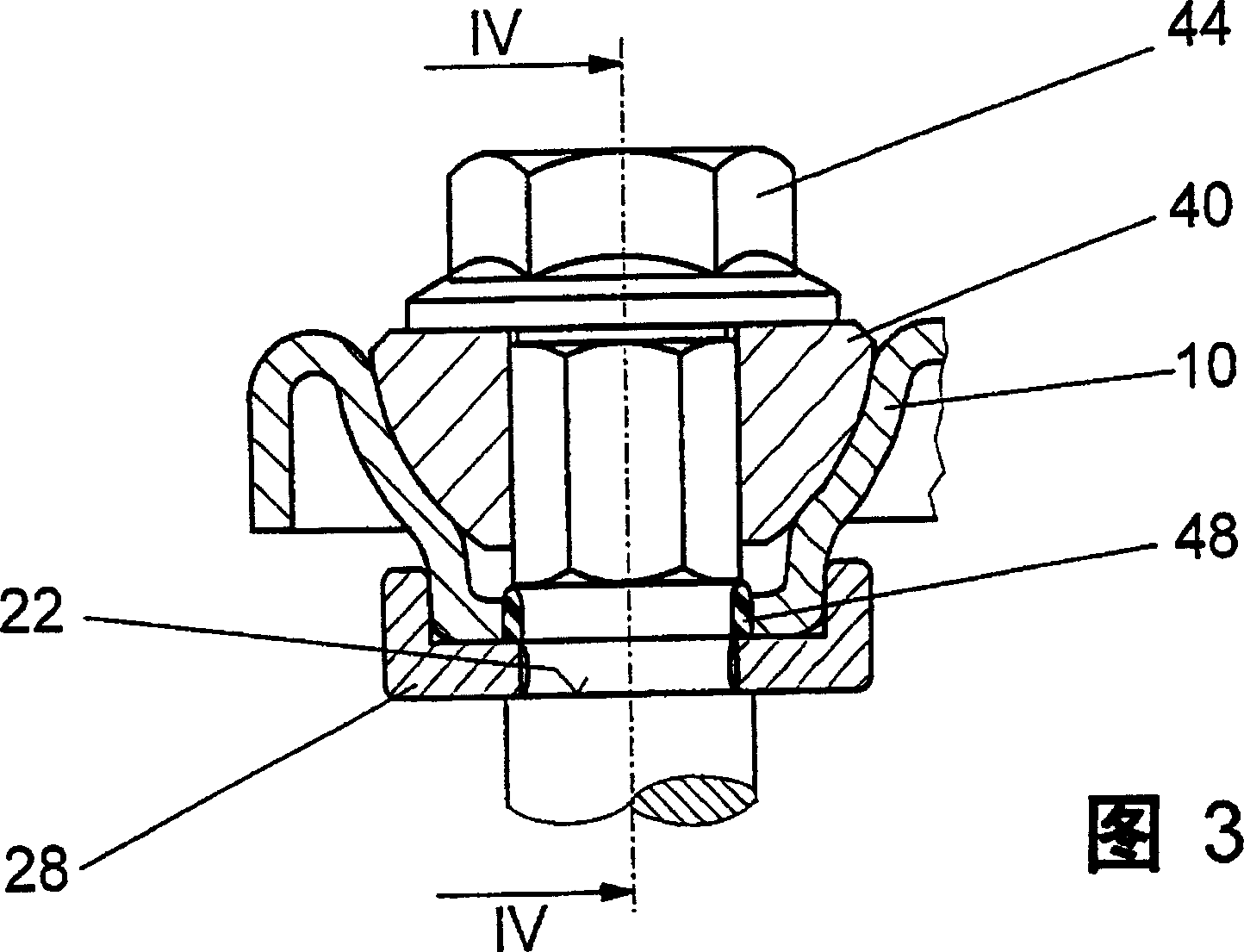

[0027]The figures show only a part of a wiper device with a wiper arm and are only necessary for understanding the invention. The components belonging to the wiper arm include a fastening component 10 which is fastened to a drive shaft 12 . The drive shaft 12 is mounted in a bearing housing 14 which has a connecting tube 16 and a fastening eye 18 for a wiper carrier, not shown here. Through the latter, the bearing housing 14 is fastened to a not-shown vehicle body. The drive shaft 12 is driven by a wiper motor via a lever drive and a crank 20 which is fixedly connected at one end to the drive shaft 12 . The free end of the drive shaft 12 has a shoulder 22 and a profile 24 with a polygonal cross-section and a thread 26 connected thereto. On the free end of the drive shaft 12 is inserted a washer 28 which is supported on the shoulder 22 but is able to rotate about the drive shaft 12 . A concave cylindrical bearing surface 30 is formed in the washer 28 toward the fastening com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com