Rapid metal plate cutting device and using method thereof

A technology for fast cutting and sheet metal, applied in the direction of metal sawing equipment, sawing device, feeding device, etc., to achieve the effect of easy to use and easy to use

Active Publication Date: 2022-06-10

曹会朝

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002]In the process of sheet metal processing, it is often necessary to use a fast cutting device to cut the sheet metal, so as to cut the sheet metal into a suitable length, and the existing sheet metal is fast When the cutting device is in use, the conveyor belt structure is generally required to transport the sheet metal, and the cutting structure is pushed by the displacement structure to cut the metal sheet, which requires more power structures and is inconvenient to use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

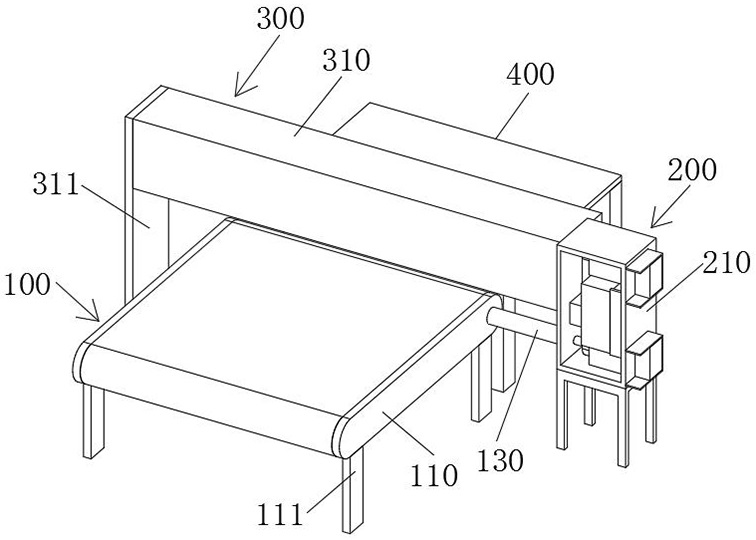

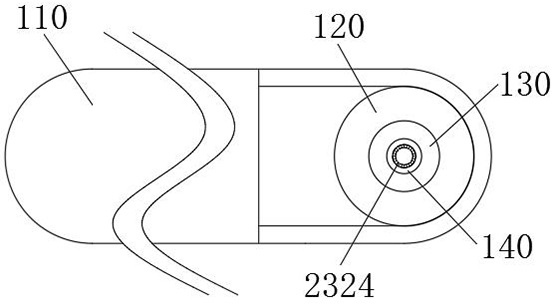

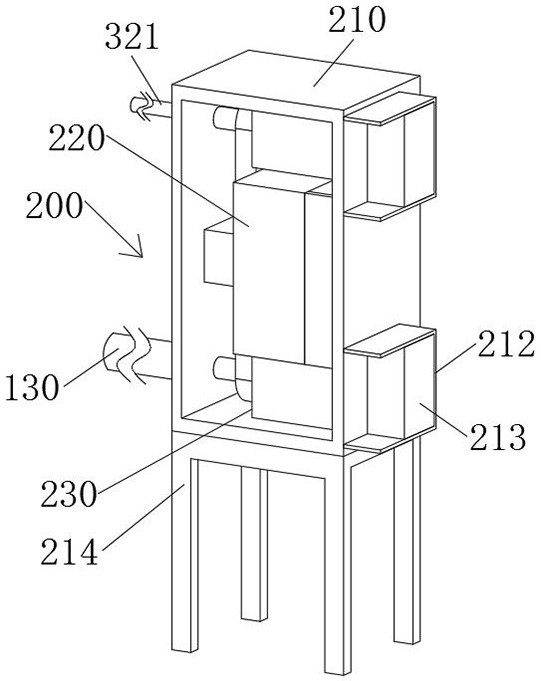

The invention relates to the technical field of metal plate cutting, in particular to a rapid metal plate cutting device and a using method thereof.The rapid metal plate cutting device comprises a conveying module and a cutting module, the cutting module is fixedly connected with an adjusting module, the adjusting module comprises a fixing frame, and the side face of the fixing frame is fixedly connected with the cutting module; transmission mechanisms are fixedly connected to the inner top face and the inner bottom face of the fixing frame, and the transmission mechanism located at the top is in transmission connection with the cutting module. According to the metal plate cutting device, the side face of a round rod is fixedly sleeved with a third gear, a first motor can drive a cutting module to cut a metal plate through a transmission mechanism located at the top, and the position of a transmission rod can be moved, so that the first gear and a second gear are both engaged with the third gear located at the bottom; therefore, the first motor drives the transmission module through the transmission mechanism located at the bottom to drive the transmission module, more power structures do not need to be arranged, and use is convenient.

Description

technical field [0001] The invention relates to the technical field of sheet metal cutting, in particular to a fast cutting device for sheet metal and a method for using the same. Background technique [0002] In the process of metal sheet processing, it is often necessary to use a fast cutting device to cut the metal sheet, so as to cut the metal sheet into a suitable length. When the existing metal sheet fast cutting device is used, it generally needs a conveyor belt structure to transport the sheet , and the cutting structure is pushed by the displacement structure to cut the sheet metal, which makes it necessary to set up more power structures and is inconvenient to use. Contents of the invention [0003] In order to overcome the above-mentioned technical problems, the object of the present invention is to provide a rapid cutting device for sheet metal and its use method. The gear 3 is fixedly sleeved on the side of the round rod, and the motor 1 can drive the cutting ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23D47/04B23D47/12B23Q5/40

CPCB23D47/042B23D47/12B23Q5/40Y02P70/10

Inventor 曹会朝王彦章

Owner 曹会朝

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com