Vibration isolation coupling design and forming process

A molding process and coupling technology, used in couplings, elastic couplings, mechanical equipment, etc., can solve the problems of raising the vibration level of the whole machine, and achieve the effect of reducing the vibration level and eliminating vibration coupling.

Pending Publication Date: 2022-06-07

AEROSPACE SHENZHOU AIRCRAFT

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In this type of unmanned helicopter, the vibration generated by the engine and the vibration generated by the rotor are coupled on the transmission system, which is likely to cause an increase in the vibration level of the whole machine. The vibration coupling between each other cannot be avoided, and the influence on the transmission system still exists

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

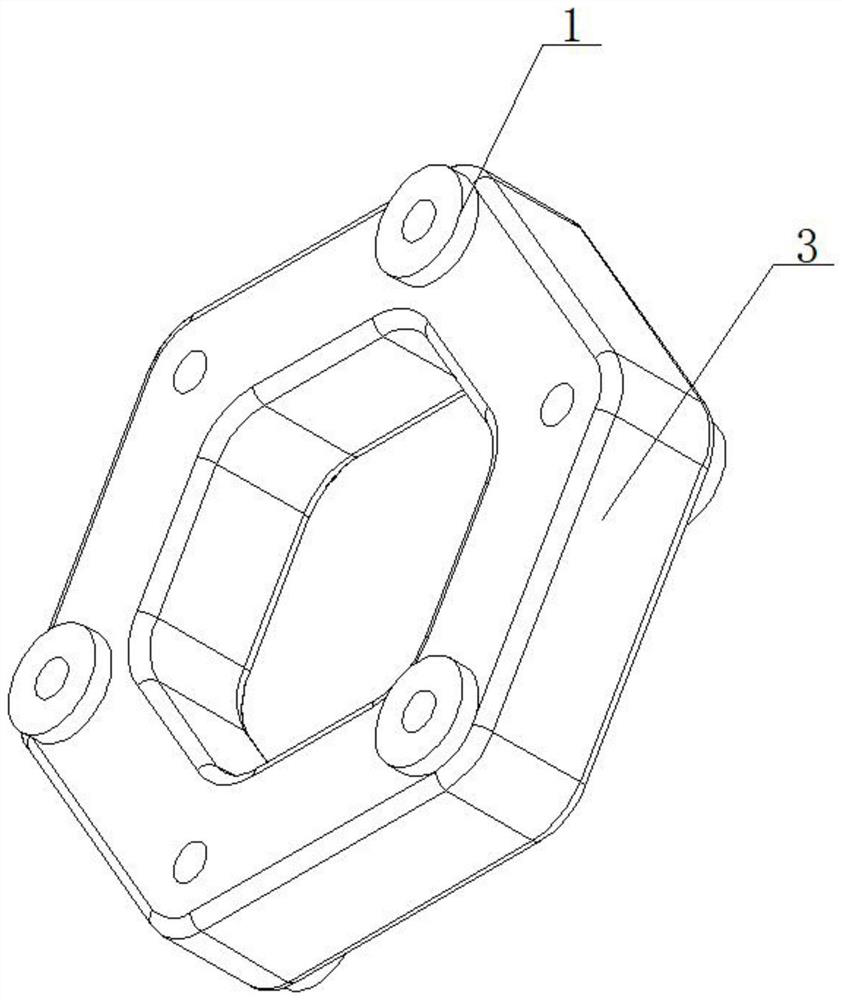

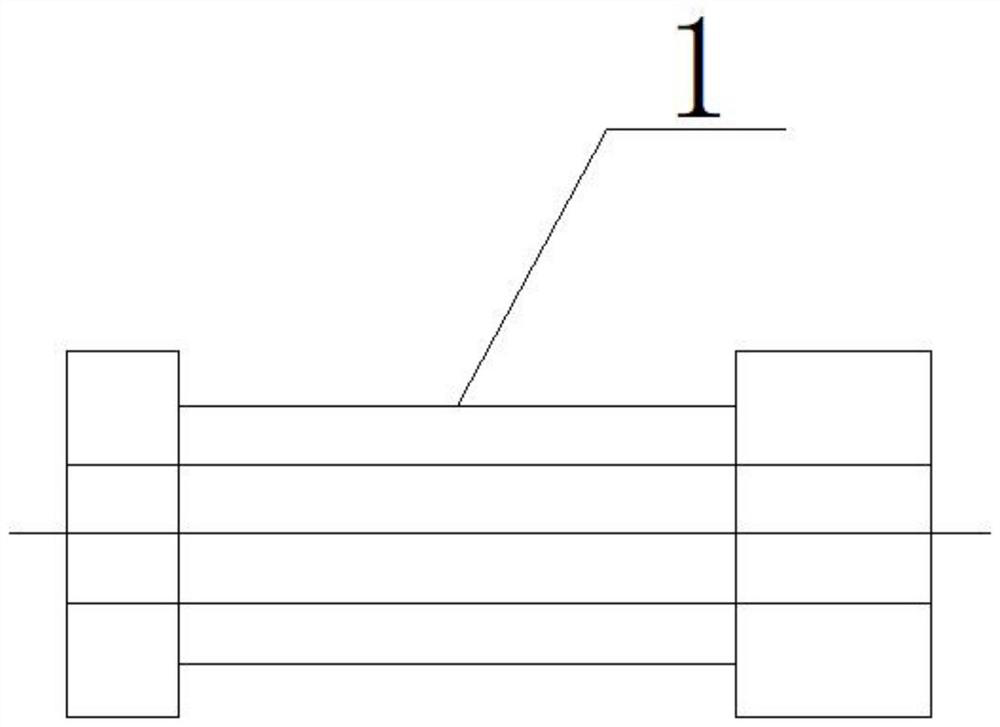

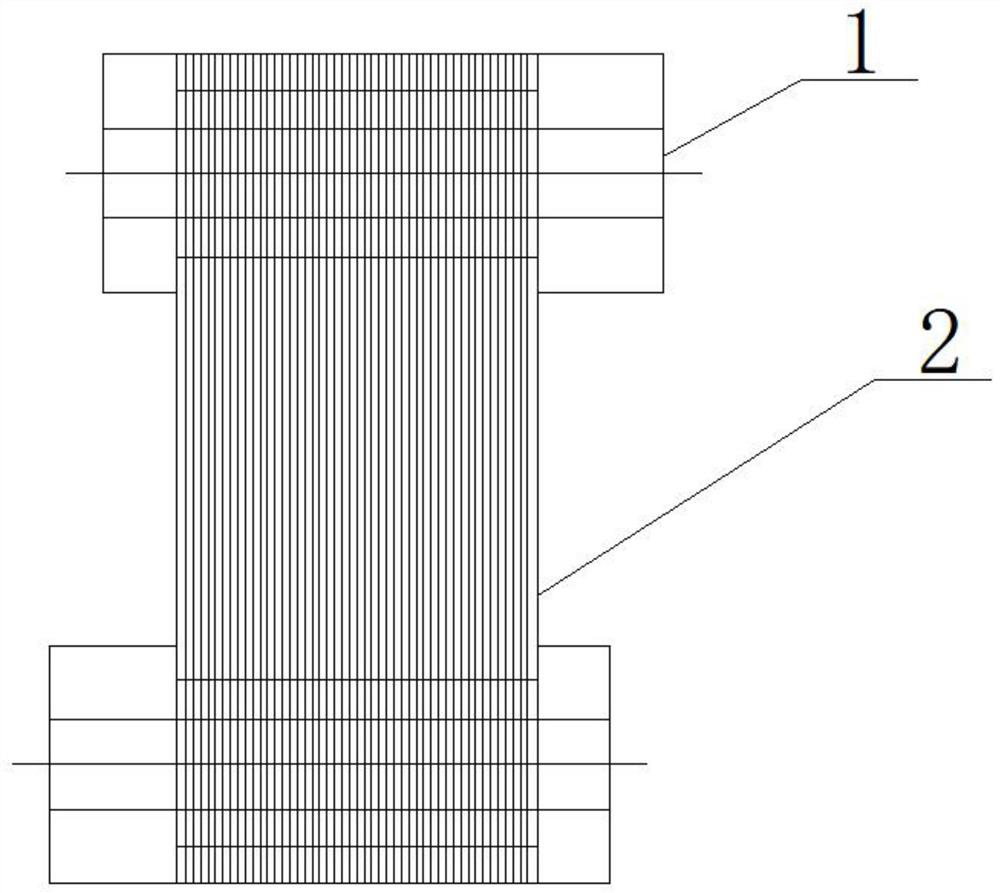

[0031] As a preferred embodiment of the present invention, metal pins are installed inside the metal pin sleeve 1 , and vulcanized rubber fillers are installed inside the vulcanized rubber 3 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a vibration isolation coupling design and forming process which comprises a vibration isolation coupling device body and is characterized in that the vibration isolation coupling device body comprises vulcanized rubber, a metal pin sleeve is mounted on the vulcanized rubber, a metal pin is mounted in the metal pin sleeve, and the metal pin is mounted in the metal pin sleeve. The metal pin sleeves are connected with each other through a Kailaff fiber bundle, a vulcanized rubber filler is mounted in the vulcanized rubber, a coupling end piece is mounted on the vulcanized rubber, and the coupling end piece is matched with the vulcanized rubber through a connecting bolt. While torque transmission is met, the vibration isolation capacity is achieved, vibration coupling is eliminated, and the vibration level of the whole machine is reduced.

Description

technical field [0001] The invention relates to the field of unmanned helicopter equipment, in particular to a design and molding process of a vibration isolation coupling. Background technique [0002] In recent years, the development speed of unmanned helicopters has been extremely rapid, and they have been widely used in many industries. At the same time that unmanned helicopters are used in various industries, the vibration coupling phenomenon of unmanned helicopters has seriously affected the structure of unmanned helicopters. life, especially for unmanned helicopters with piston engines. In this type of unmanned helicopter, the vibration generated by the engine and the vibration generated by the rotor are coupled on the transmission system, which can easily lead to an increase in the vibration level of the whole machine. Although the reduction of the rotor system and the engine alone can play some role, The vibration coupling between them cannot be avoided, and the in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B29C45/14F16D3/12

CPCB29C45/14F16D3/12B29C2045/1486

Inventor 刘涛姜明泽高晨李广磊

Owner AEROSPACE SHENZHOU AIRCRAFT

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com