Bead embroidering and supplementing device capable of intelligently supplementing beads and bead embroidering machine

A bead and supply technology, applied in the field of embroidery machines, can solve the problem of reducing the probability of successful beading, and achieve the effects of reducing labor intensity, ensuring the success rate of beading, and increasing supply efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

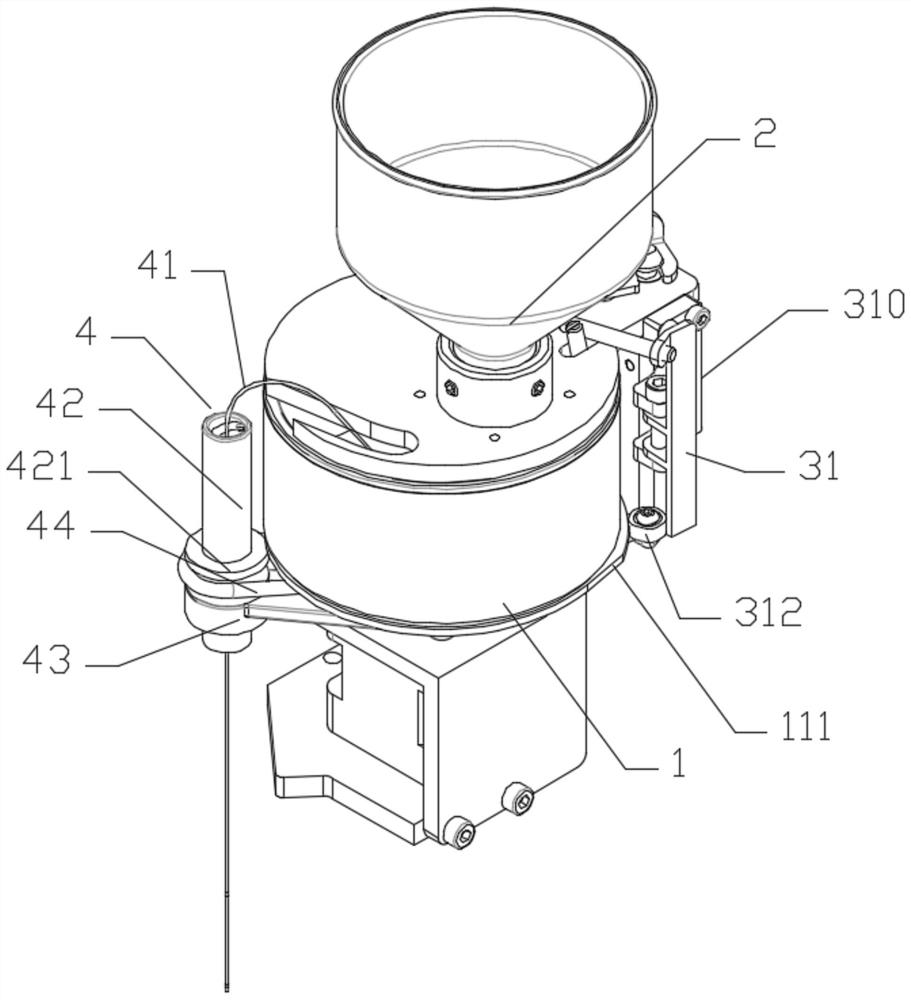

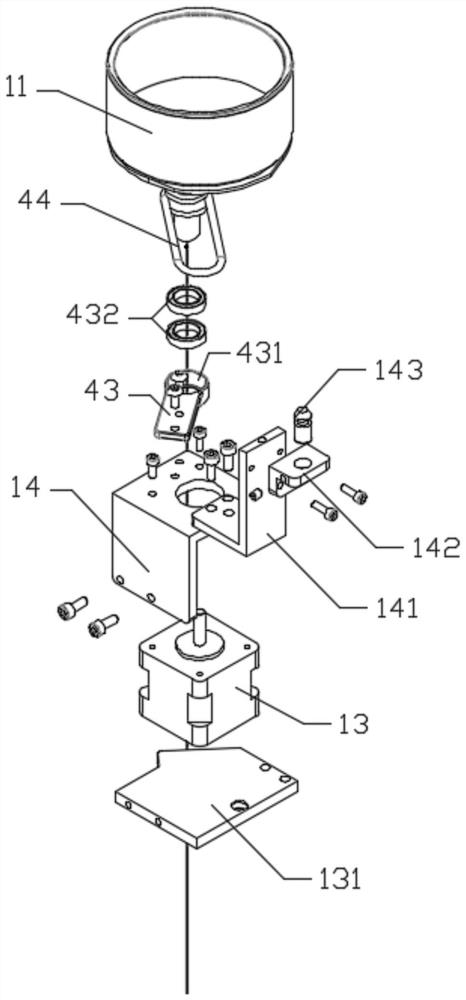

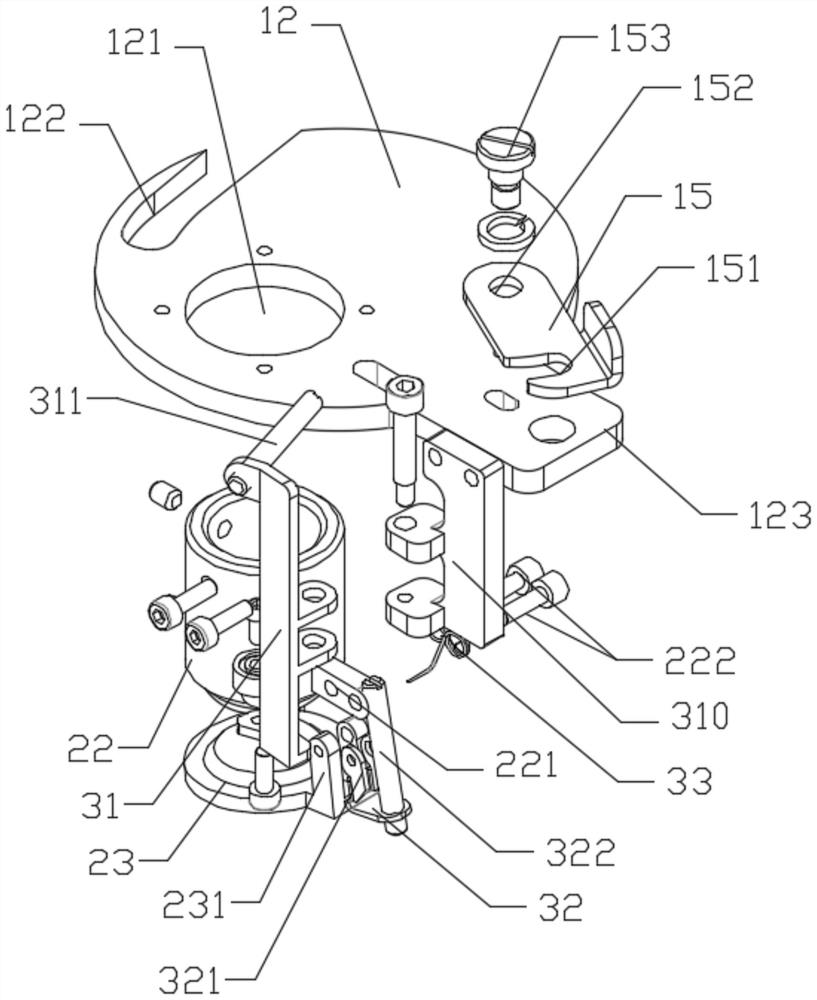

[0030] like Figure 1 to Figure 5 As shown, the present invention provides a bead embroidery and bead replenishing device for intelligently replenishing beads, which includes a tray assembly 1 and a bead replenishment assembly 2 . The tray assembly 1 includes a tray 11 with a cavity, a cover plate 12 arranged above the tray, and a tray motor 13 for driving the tray 11 to rotate. The cover plate 12 is suspended on the material tray 11 to cover the opening above the material tray. When the material tray 11 rotates, the cover plate 12 is fixed. The bead replenishing assembly 2 includes a feeding funnel 21 located above the feeding tray 11, the bottom of the feeding funnel 21 is provided with a feeder 22, the feeding device 22 is installed on the cover plate 12, and the bottom of the feeding device 22 It is located inside the tray and has a discharge opening. The feeder 22 is hinged with a discharge valve 23 that can be turned up and down to open and close the discharge port, an...

Embodiment 2

[0041] With reference to the prior art, on the basis of Embodiment 1, a beading mechanism 4 is also provided. The beading mechanism 4 includes a beading steel wire 41, and the beads output from the tray 11 are connected in series by the beading steel wire 41, and guide the beads to be conveyed downward.

[0042] In this embodiment, the beaded steel wire 41 includes a bead section and a lower bead section, the head end of the bead section extends into the tray, the lower bead section extends from top to bottom, and the upper end of the bead section is connected to the bottom of the bead section. The tail ends are connected, and the cover plate 12 is provided with an open slot 122 , and the bead section passes through the open slot 122 . Through the rotation of the material tray, the inner beads are driven to make a circular motion. Under the action of the inertia of the beads, the beads penetrate into the head of the bead segment and are arranged in a string in sequence. delive...

Embodiment 3

[0047] This embodiment relates to a bead embroidery machine, which includes the intermittent automatic bead filling device for bead embroidery described in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com