Method for determining positions of diaphragm and dental model, diaphragm and selection method and system

A technology of relative positional relationship and diaphragm, applied in manufacturing computing systems, dentistry, orthodontics, etc., can solve the problems of diaphragm material waste and increase production cost, and achieve the effect of reducing production cost, improving efficiency and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

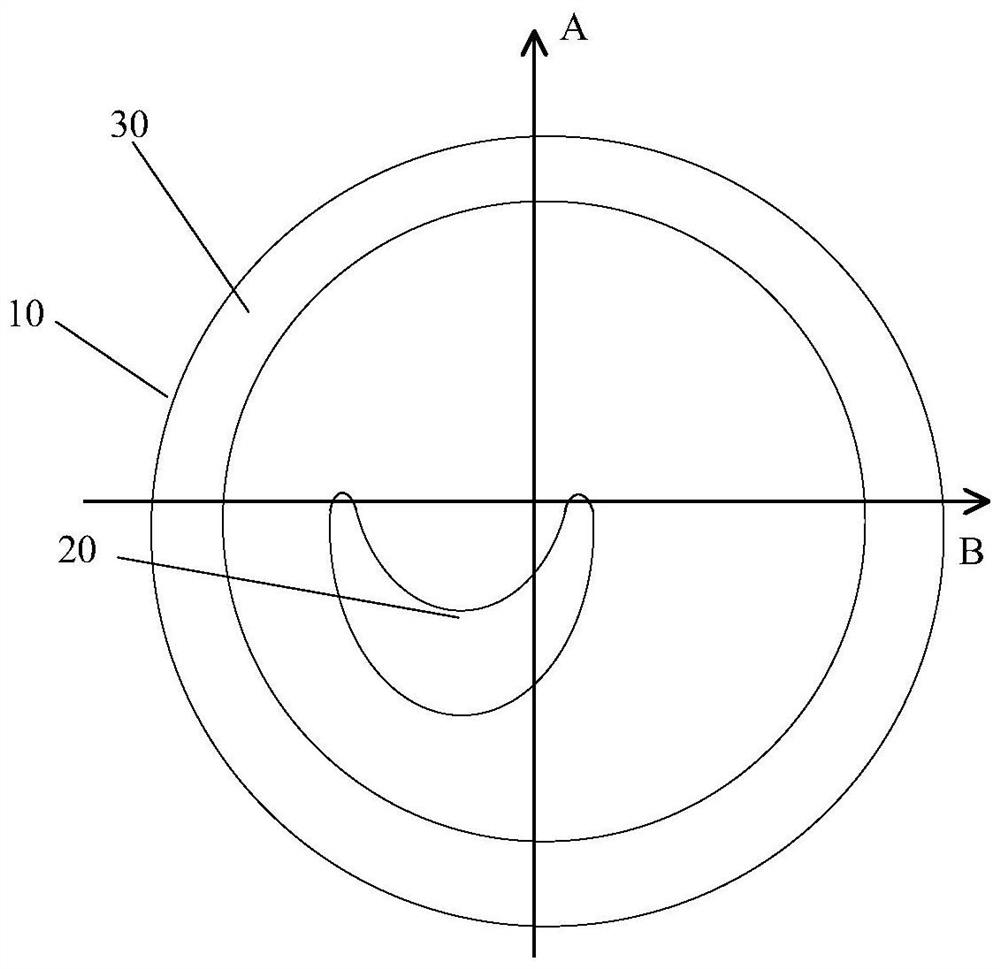

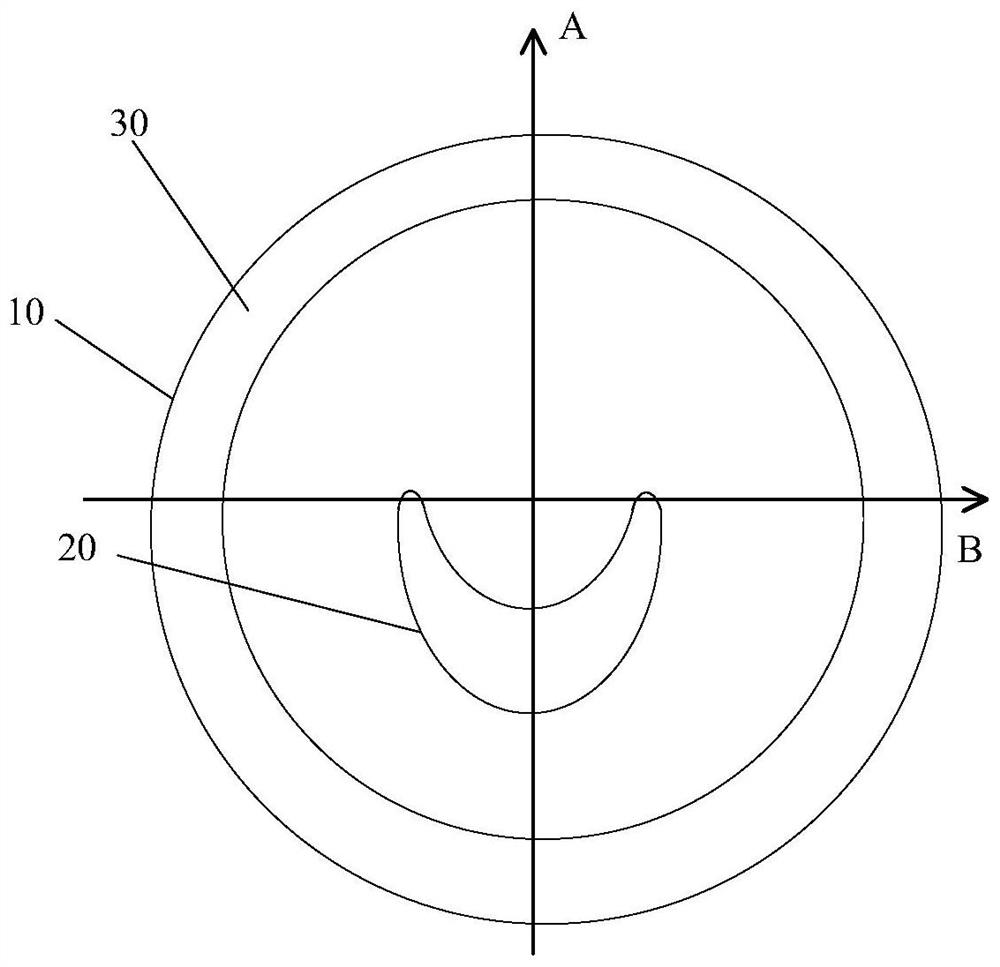

[0068] A method for determining the relative positional relationship between a diaphragm data model and a dental-jaw data model, which is used in the production process of shell-shaped dental appliances. The digital model formed, the dental and jaw data model is a digital model formed by using digital technology to perform three-dimensional modeling of the dental and jaw model in actual production. In one embodiment, the shape of the diaphragm data model is circular, and its specifications can be The selection is made according to actual production requirements. More specifically, the diaphragm data model is a circular sheet-like structure with a radius of 30mm-80mm.

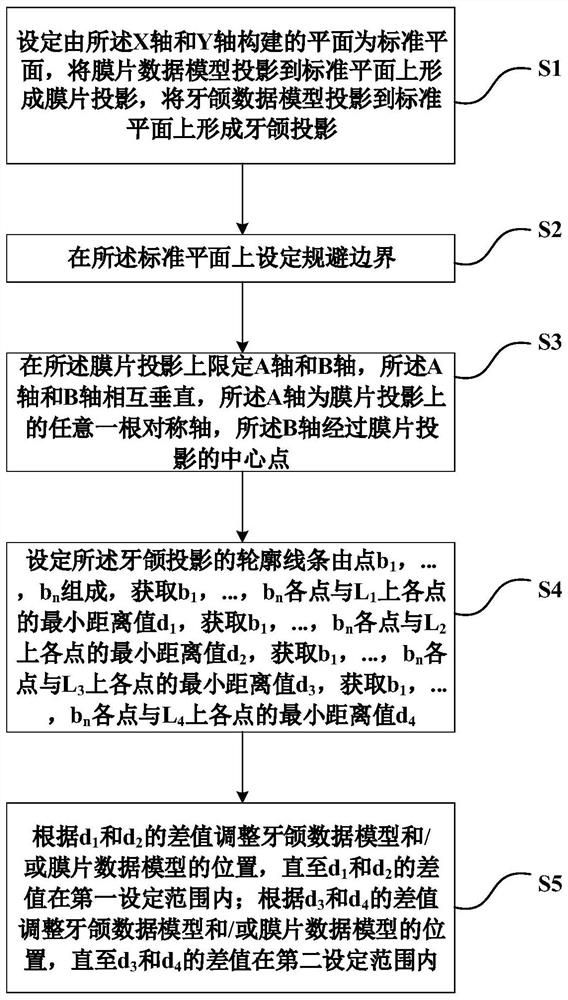

[0069] like figure 1 As shown in the figure, the method for determining the relative positional relationship between the diaphragm data model and the dental jaw data model includes the following steps:

[0070] S1. Establish a space coordinate system, the space coordinate system includes an X axis, a Y axis and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com