Performance detection device for electric power insulation safety tool

A technology for insulation safety and detection devices, applied in the direction of testing dielectric strength, etc., can solve problems such as increased manual workload, hidden safety hazards, damage, etc., and achieve the effect of improving work efficiency and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

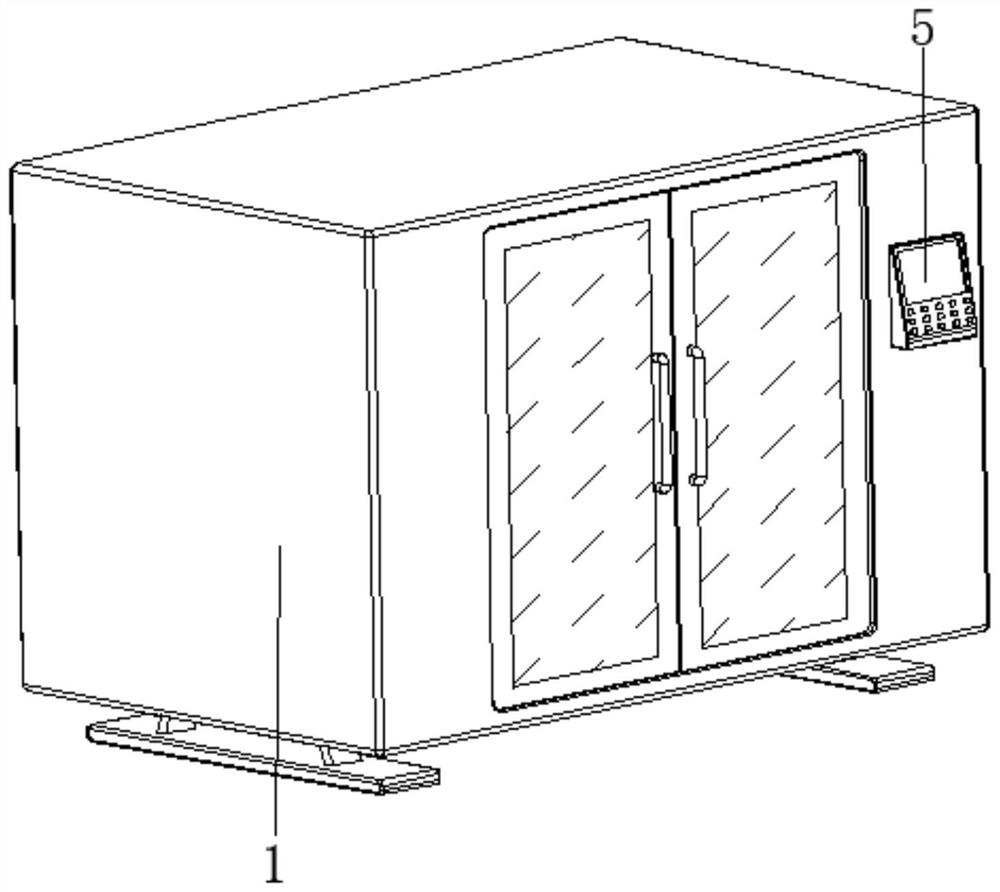

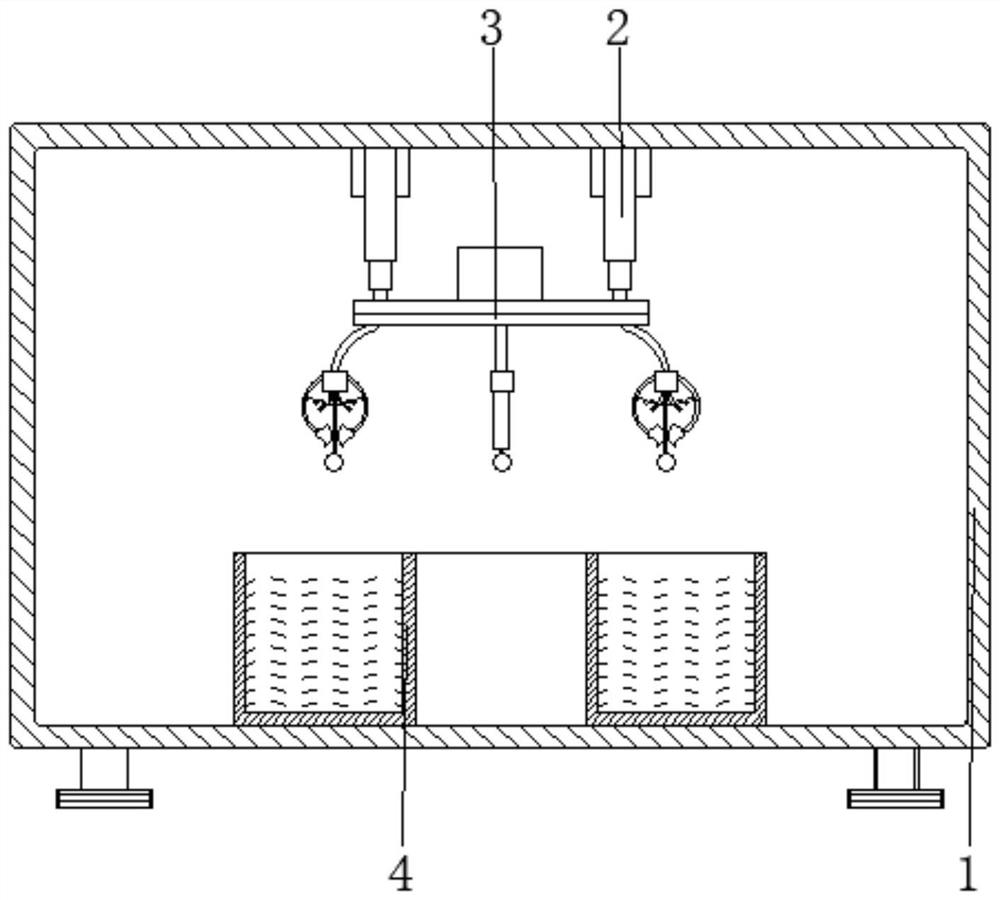

[0030] see Figure 1-7 , the present invention provides a technical solution: a performance detection device for electrical insulation safety tools, including a body 1, a lifting mechanism 2, and a processing device 3, the top of the lifting mechanism 2 is fixedly connected to the top of the inner wall of the body 1, and the processing device 3 set at the output end of the lifting mechanism 2;

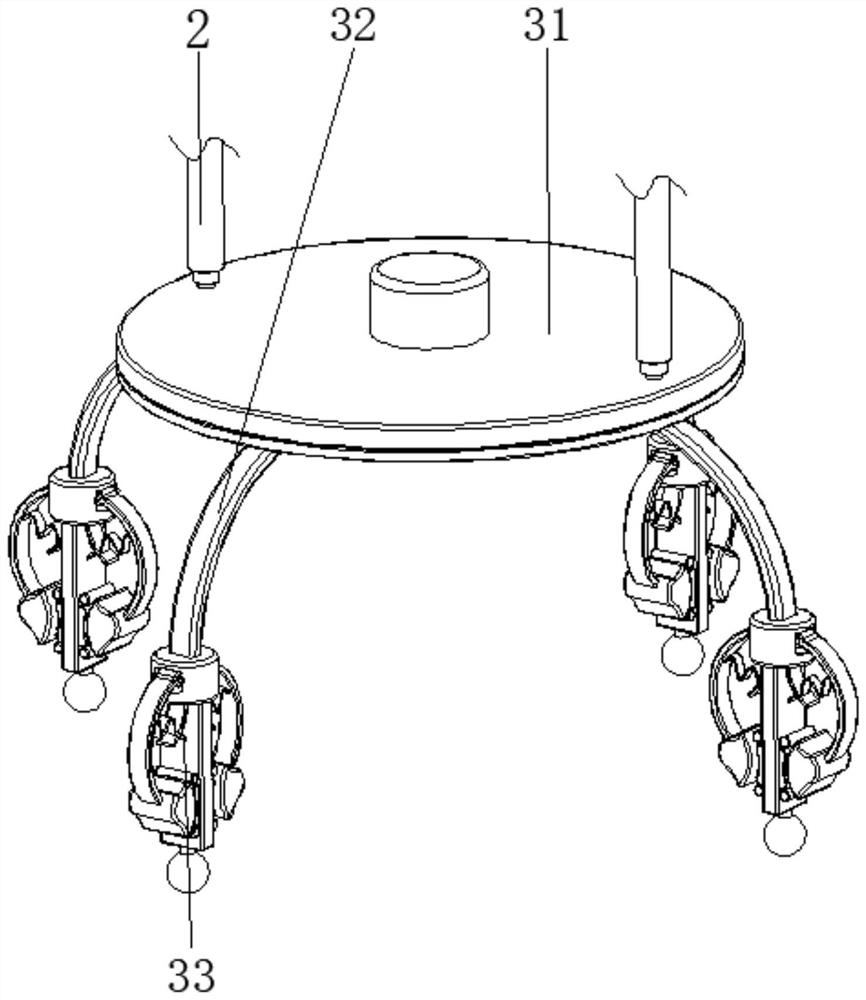

[0031] The processing device 3 is provided with a drive turntable 31, an arc-shaped support rod 32, and a clamping test device 33. The top edge position of the drive turntable 31 is fixedly connected to the output end of the lifting mechanism 2, and the top end of the arc-shaped support rod 32 is connected to the end of the drive turntable 31. The bottom edge is fixedly connected, and the clamping test device 33 is arranged on the bottom end of the arc-shaped support rod 32;

[0032] A water tank 4 is arranged at the bottom of the inner wall of the body 1 and near the center. The posi...

Embodiment 2

[0034] The clamping test device 33 is provided with a base body 331, an arc-shaped pressing rod 332, an indenter device 333, a fixed plate 334, a curved elastic member 335, and a testing device 336. The top of the base body 331 is fixedly connected to the bottom end of the arc-shaped support rod 32, The top of the arc-shaped pressing bar 332 is hinged with the surface of the base body 331, the pressing head device 333 is arranged at the bottom end of the arc-shaped pressing bar 332, and the top of the fixing plate 334 is fixedly connected with the bottom of the base body 331 and close to the position of the arc-shaped pressing bar 332 , the curved elastic part 335 is fixed between the two sides corresponding to the surface of the arc-shaped pressing bar 332 and the surface of the fixing plate 334, and the inspection device 336 is arranged at the bottom center of the base body 331, and the top end of the arc-shaped pressing bar 332 and the base body 331 The surface is hinged, an...

Embodiment 3

[0037] The testing device 336 is provided with a connection plate 3361, a test ball 3362, and an anti-slip device 3363. The top of the connection plate 3361 is fixedly connected to the bottom of the base body 331. The test ball 3362 is arranged at the bottom center of the connection plate 3361, and the anti-skid device 3363 is arranged on the connection plate. The bottom of the surface of 3361 and close to the location of the test ball 3362.

[0038] The anti-slip device 3363 is provided with a bump 33631, an arc-shaped concave surface 33632, and a horn protrusion 33633. One side of the surface of the bump 33631 is fixedly connected with the surface of the connecting plate 3361. The arc-shaped concave surface 33632 is set on the surface of the bump 33631 and is far away from the connecting plate. On one side of 3361, the ox horn protrusion 33633 is fixedly connected to the surface of the protrusion 33631 and is located at the position of the arc-shaped concave surface 33632. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com