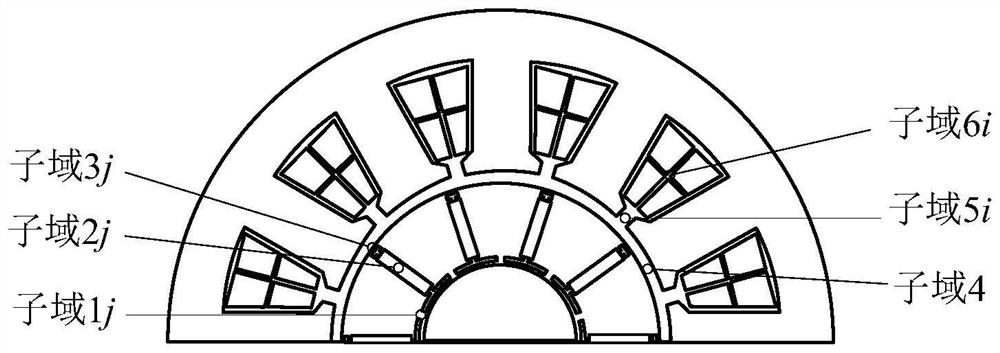

Tangential four-layer winding fractional slot permanent magnet motor flux density distribution calculation method

A permanent magnet motor and four-layer winding technology, which is applied in complex mathematical operations, design optimization/simulation, and special data processing applications, etc., can solve the problem of magnetic flux leakage and iron core saturation of the rotor magnetic isolation bridge, difficult mathematical modeling, and complex rotor structure and other problems, to achieve the effect of convenient and fast motor performance analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] Including the following steps:

[0109]Step (1), performing equivalent treatment with each magnetic isolation bridge in the permanent magnet motor rotor with a rectangular equivalent air gap, the width of the equivalent air gap is the same as the actual width of the magnetic isolation bridge;

[0110] Step (2), estimate the saturation degree of the iron core at the magnetic isolation bridge according to the actual width of a single magnetic isolation bridge, assuming that the relative permeability of the magnetic isolation bridge is μ r0 , this value is the initial value of the relative permeability in the first iterative calculation in step 3, namely μ r1 =μ r0 ;

[0111] Step (3), according to the initial value μ of the relative magnetic permeability of the iron core at the magnetic isolation bridge r1 Calculate the corresponding equivalent rectangular air gap length l a1 ;

[0112] Step (4), based on the equivalent rectangular air gap length l a1 The motor magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com