Header height regulating and controlling device and method for reducing grain loss and harvester

A control device and cutting platform technology, applied in the field of agricultural machinery, can solve the problems of not being able to judge the lowest point suitable for crop harvesting, and failing to reduce the loss rate of seeds, so as to achieve the effect of improving harvesting efficiency and profiling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

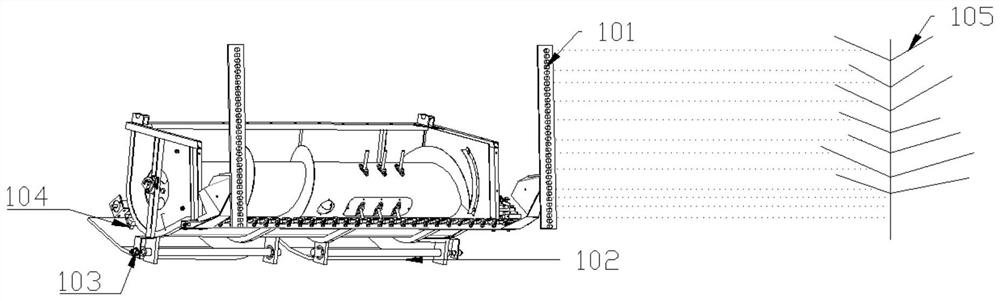

[0037] figure 1 Shown is a preferred embodiment of the header height control device for reducing grain loss, the header height control device includes a height sensor, a profiling plate 102, an angle sensor 103, an ultrasonic sensor 104, a displacement sensor and control unit.

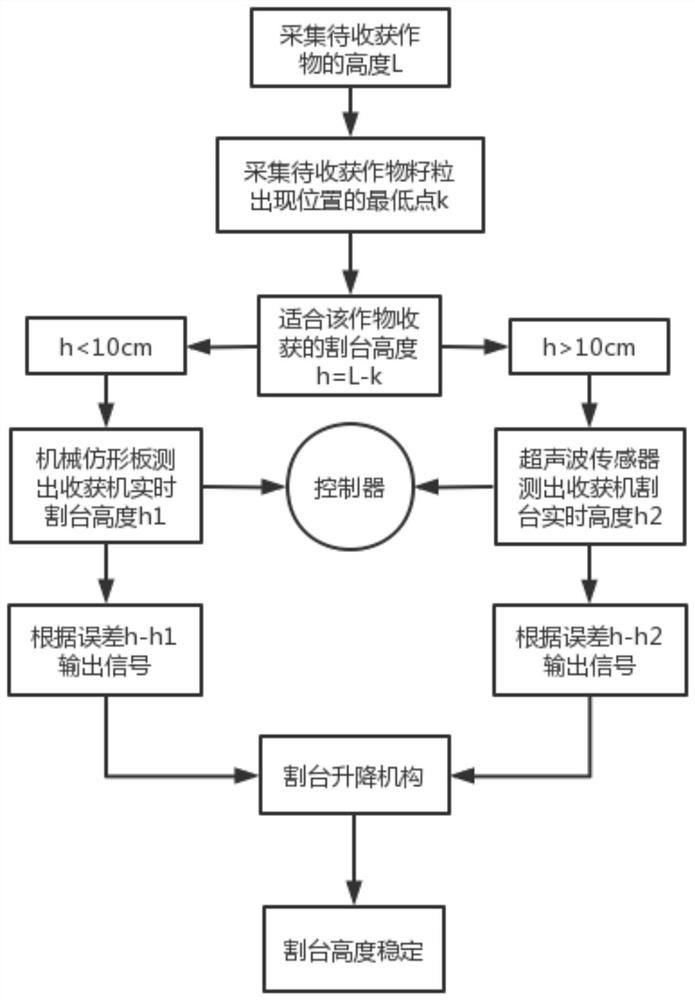

[0038] A number of height sensors are longitudinally arranged on both sides of the header, and the height sensors are used to detect the height L of the crop 105 to be harvested and the lowest position k of the grain and transmit it to the control unit; two profiling plates 102 are symmetrically arranged at the bottom of the header, Angle sensor 103 is used for measuring the angle of rotation of profiling plate 102, and is delivered to control unit; Both sides of header are respectively provided with ultrasonic sensor 104, and ultrasonic sensor 104 is used for measuring the height of header, and is delivered to control unit; The displacement sensor is used to measure the displacement of the header lif...

Embodiment 2

[0060] A harvester, comprising the header height control device for reducing grain loss described in Embodiment 1, therefore has the beneficial effects of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com