Ridging machine with adjustable ridge height and ridging method

A technology of ridging machine and ridge plate, applied in agricultural machinery and implements, agriculture, application, etc., can solve the problems of inconvenient adjustment, achieve the effects of simplifying operation distribution, improving quality, and reducing adjustment difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

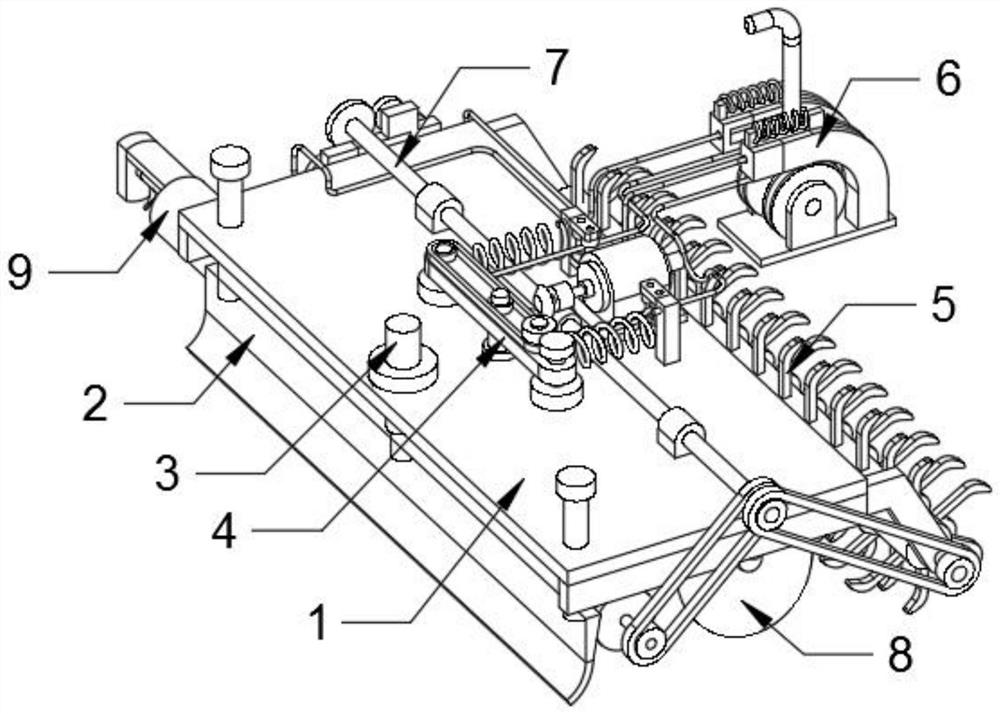

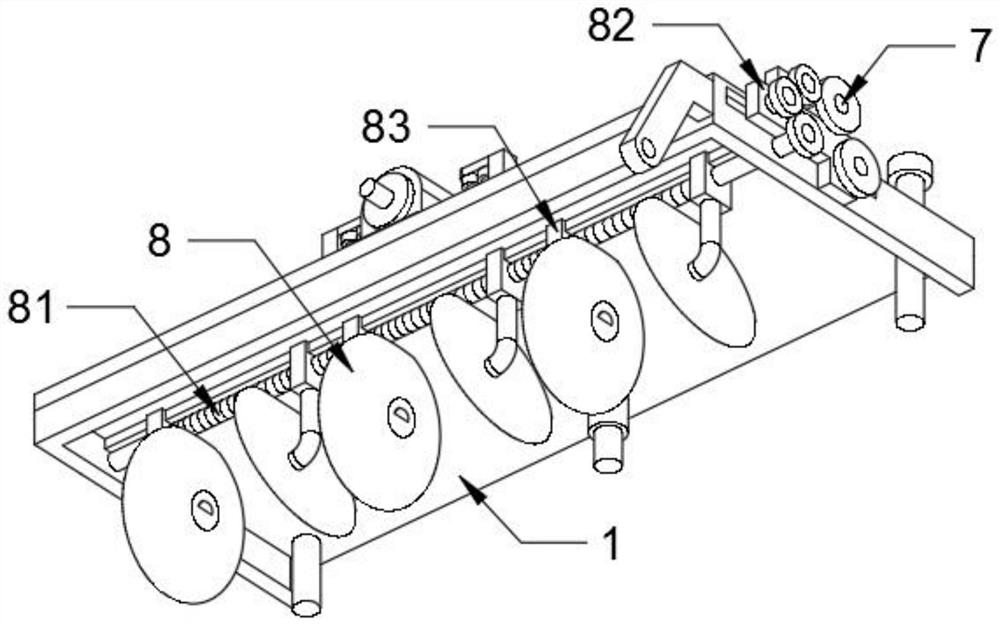

[0035] Such as Figure 1-2 As shown, a ridging machine with adjustable ridge height includes a plate frame 1, a scraper 2 is arranged at the end of the plate frame 1, and the surface of the plate frame 1 is rotated to install a screw barrel 3, and the surface of the screw barrel 3 is sleeved with gears. , the bottom of the screw barrel 3 is threaded with a stud fixed to the scraper 2, the screw barrel 3 turns left or right and pushes the stud and the scraper 2 up or down through the thread, and the top surface of the plate frame 1 is equipped with a swing Part 4, the swinging part 4 is connected with a regulator 6 through two sets of steel wires, and the regulator 6 pulls the swinging part 4 to turn left or right through the steel wire, so that the left or right end of the swinging part 4 contacts the gear on the surface of the screw barrel 3;

[0036] A shaft coupling is installed on the surface of the plate frame 1, and a shaft rod 7 is installed on the surface of the plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com