Dirt cleaning method for fan

A fan and decontamination technology, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of inconvenient operation, complex structure and low efficiency of Roots blower, and achieve clean and no dirt residual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In the WSA wet acid plant, fans are often used to pressurize the gas. In the acid making device, the low-end interface of the blower is connected with the gas inlet pipeline, and the high-end interface of the blower is connected with the gas outlet pipeline, so as to transport the gas to the incinerator for combustion. At present, Roots blower is often used to pressurize coke oven gas. After running for a long time, impurities such as tar and dust in the coke oven gas will be deposited on the fan rotor. These deposited tar, dust, etc. will increase the running resistance of the Roots blower, which not only causes the body of the Roots blower to heat up, reduces the operation efficiency of the Roots blower, but also causes the rotor of the fan to vibrate greatly, thereby damaging the Roots blower.

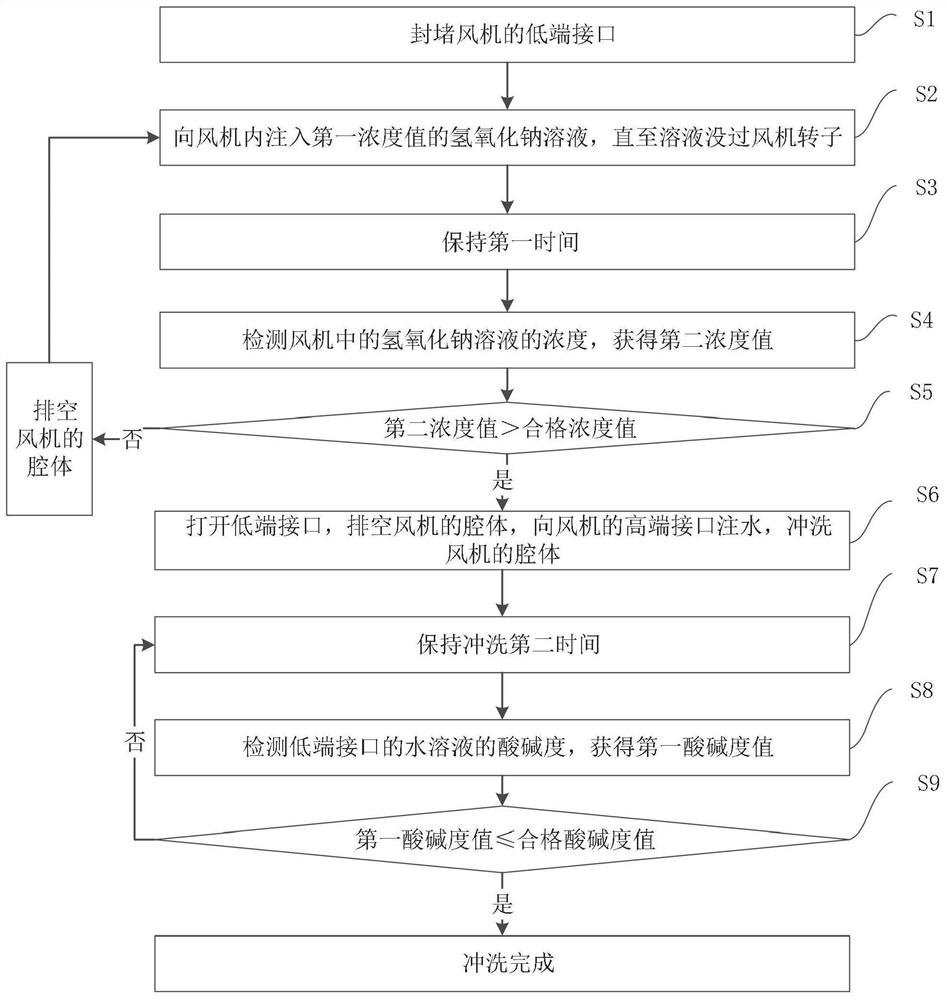

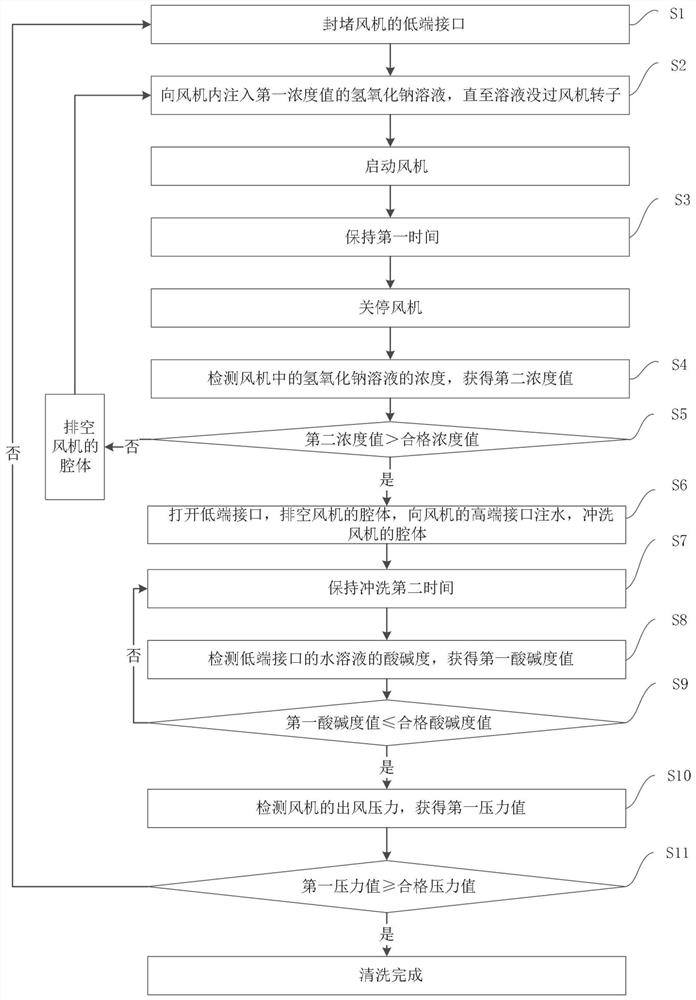

[0042] In order to efficiently remove impurities such as tar in the Roots blower, this embodiment provides a cleaning method for the blower. The decontamination method can ...

Embodiment 2

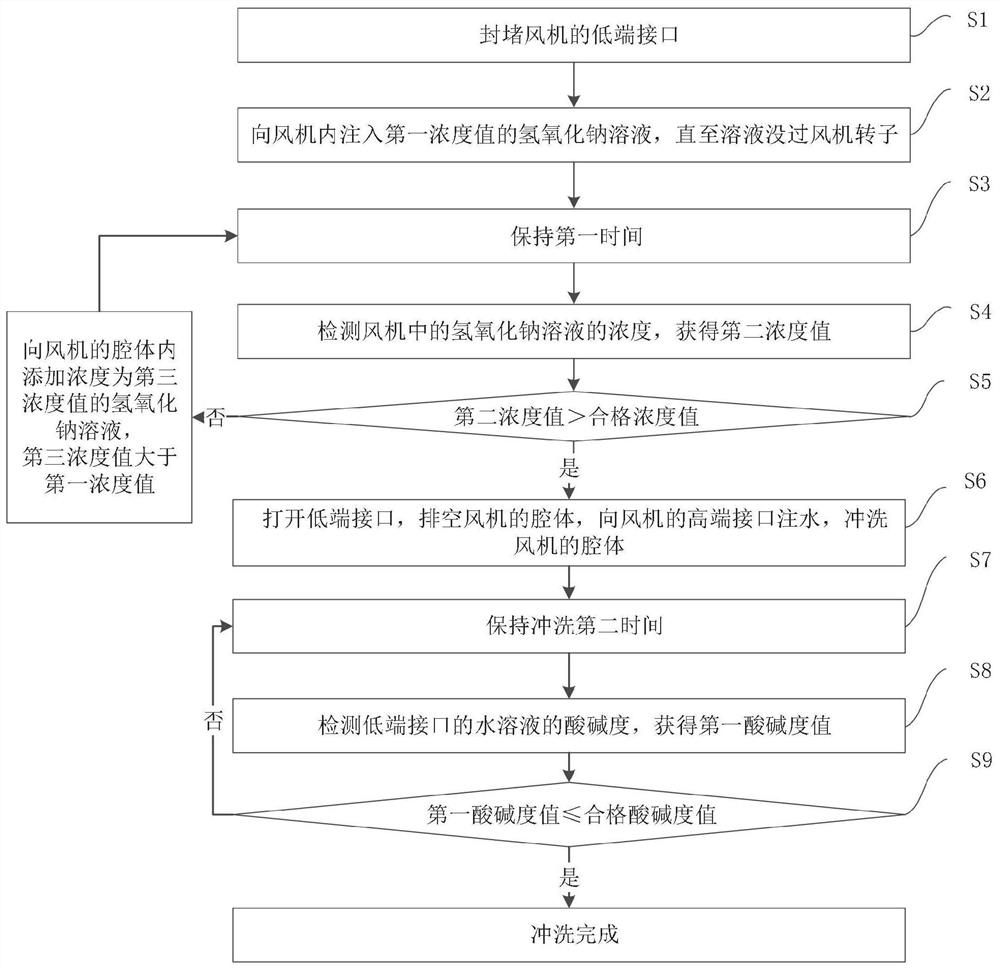

[0059] The decontamination method for the fan provided in this embodiment is basically the same as the first implementation, the main difference is that in this embodiment, as image 3 As shown, step S5 is: if the second concentration value is not greater than the qualified concentration value, then add a sodium hydroxide solution with a concentration of a third concentration value in the cavity of the fan, the third concentration value is greater than the first concentration value, and repeat the steps S3-S4. Otherwise proceed to the next step. That is to say, directly adding high-concentration sodium hydroxide solution to the original solution can continue to clean the cavity of the Roots blower without repeated replacement of the cleaned mixed solution, which not only saves cleaning time, but also improves cleaning efficiency. Also avoid the waste of sodium hydroxide and water in the original solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com