Food insulation board

A technology of plate body and protection switch, applied in the direction of coupling device, ohmic resistance heating parts, base/casing, etc., can solve the problems of occupying use space, limited use space, hindering the flexibility of personnel, etc., to improve structural stability, The effect of preventing foot swing and saving storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

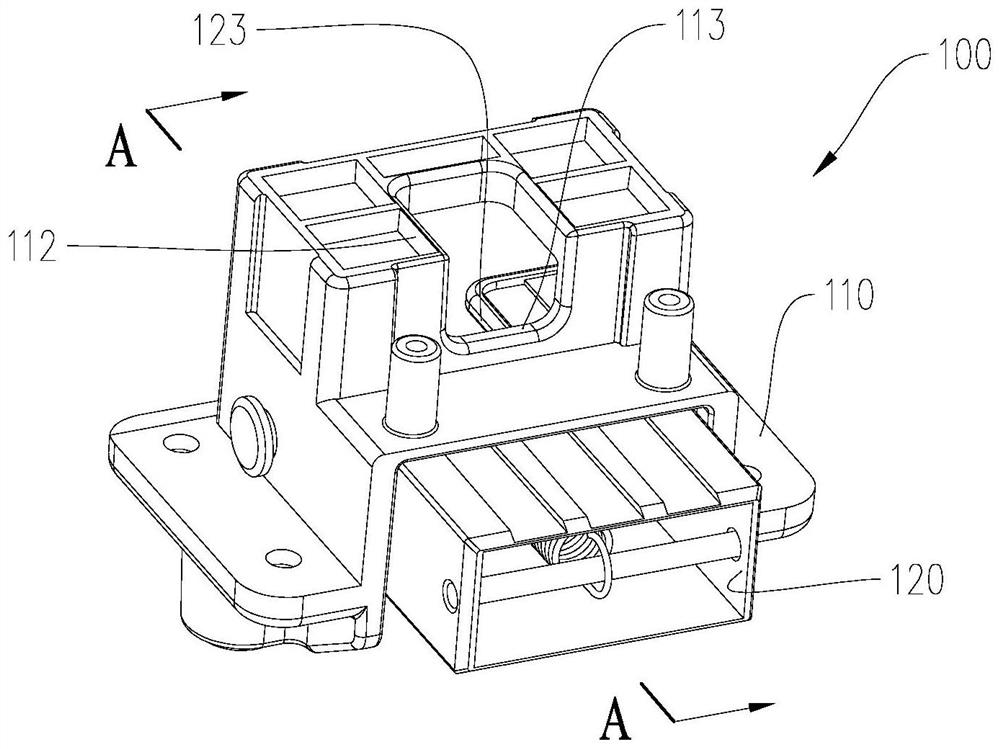

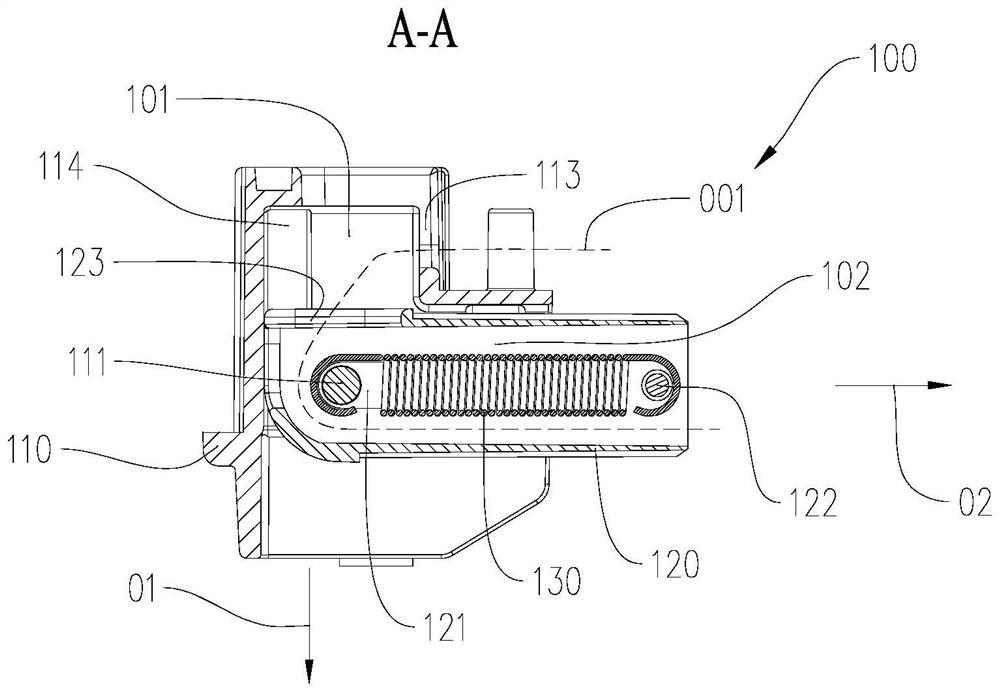

[0041] Such as Figure 1-2 As shown, the folding joint 100 is in a folded state.

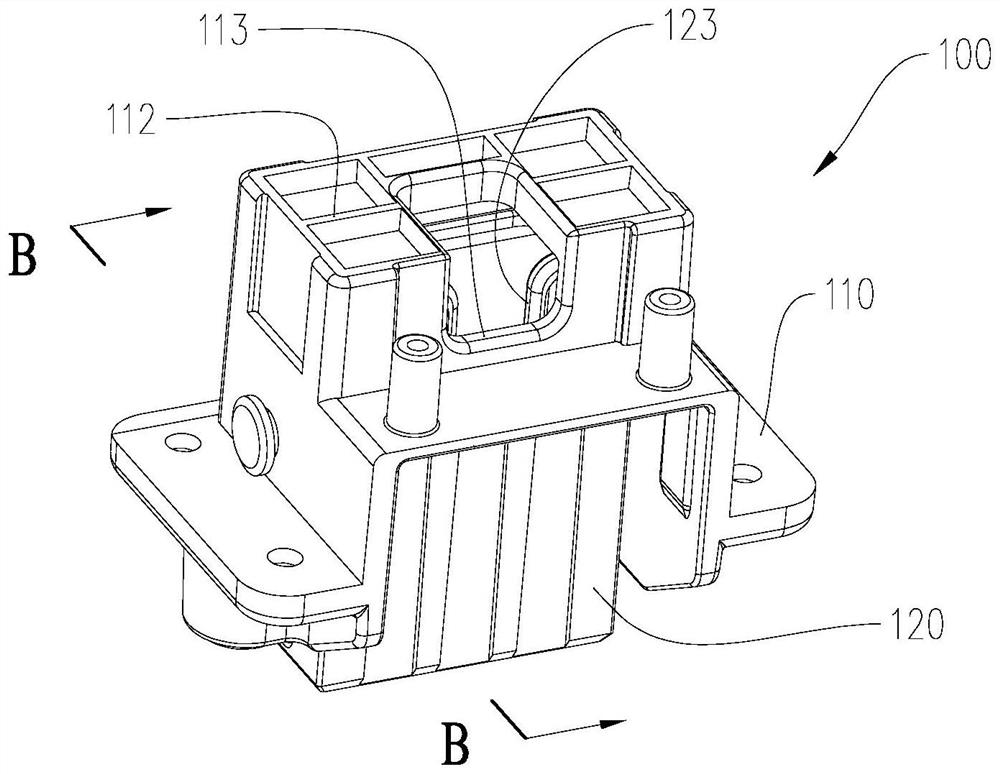

[0042] Such as Figure 3-4 As shown, the folding joint 100 is in an extended state.

[0043]The fold joint 100 is used for the foot fold of the food warmer. The folding joint 100 includes a base 110 and a movable block 120 . The base 110 is provided with a first groove 101 extending along the unfolding direction 01 and a second groove 102 extending along the folding direction 02 , and the unfolding direction 01 intersects the folding direction 02 . The rotating shaft 111 is fixed on the base 110, located at the intersection of the first groove 101 and the second groove 102, and perpendicular to the plane formed by the unfolding direction 01 and the folding direction 02. The movable block 120 is rod-shaped, and the first end of the movable block 120 is provided with an elongated hole 121 extending along its axial direction, the rotating shaft 111 passes through the elongated hole 121, and the...

Embodiment 2

[0051] Such as Figure 5 As mentioned above, the difference between this embodiment and the previous embodiments is that there is no avoidance gap and corresponding reinforcing rib on the base 210 of the folding joint 200 , and there is no avoidance opening on the movable block 220 . In this way, the mold making process can be simplified and the manufacturing cost can be saved.

[0052] Examples of food warming boards:

[0053] Such as Figure 6 and Figure 7 As shown, the food warming board 1000 includes a first food warming board 1100 and a second food warming board 1200 .

[0054] The first food warming board 1100 includes a first board body 1110 and a first heating element (not shown in the figure) installed in the first board body 1110 . The switch 1111 is used to control the power on and off of the first heating element. The indicator light 1112 is used to indicate the power on and off of the first heating element. The first heating element is covered with a temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com