Double-cavity air cylinder piston type pulsating pressure generator

A pressure generator, cylinder piston technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problem of unable to generate pulsating pressure, achieve the effect of increasing amplitude, increasing pressure amplitude, and reducing waveform distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

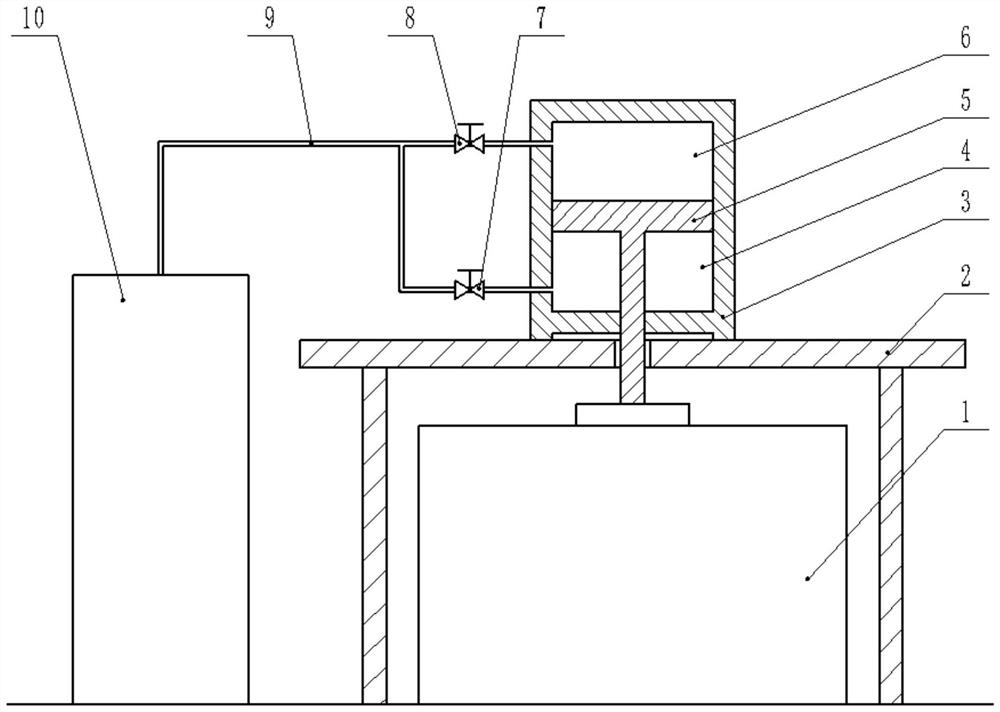

[0026] Such as figure 1 As shown, this embodiment discloses a double-cavity cylinder piston type pulsating pressure generator, including a vibrating table 1, a base 2, a cylinder 3, a piston 5, an air pressure source 10, an air circuit 9 and a valve. The cylinder 3 is installed on the base 2, the edge of the piston 5 is dynamically sealed with the inner wall of the cylinder 3, and the hole under the piston 5 is dynamically sealed with the cylinder 3. The vibrating table 1 drives the piston 5 to move back and forth to generate sinusoidal regular pressure in the two chambers. The air pressure source 10 is connected to the cylinder 3 through the air circuit 9, and the two valves respectively control the two chambers to adjust the initial pressure in the cylinder 3, and the average value of the generated pulsating pressure covers positive pressure and negative pressure.

[0027] The two valves are valve a7 and valve b8 respectively. The two independent chambers are air chamber a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com