Integral wing and aileron driving device and mounting method

A driving device, integrated technology, applied in the direction of aircraft transmission, aircraft power device, aircraft power transmission, etc. problems, to achieve the effect of ensuring fluency and transmission capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

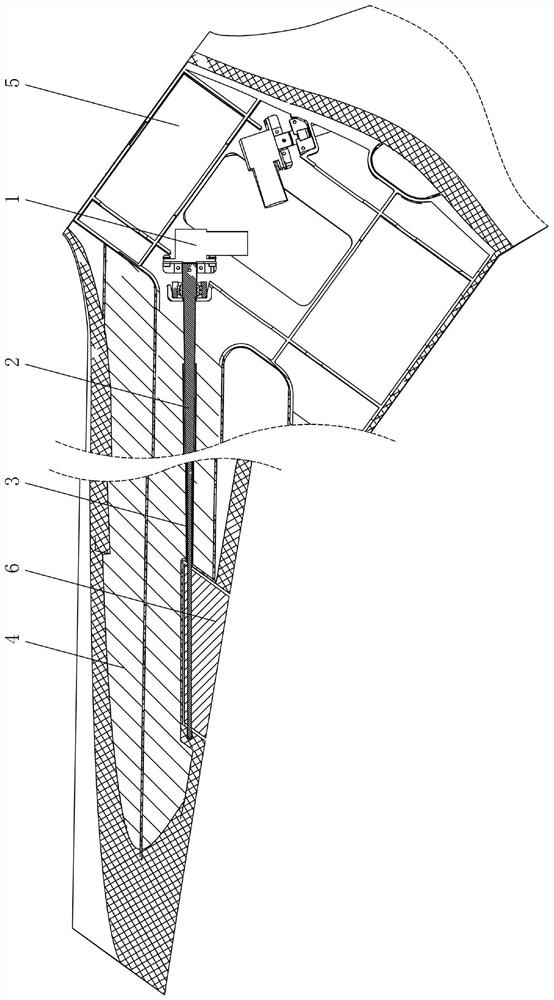

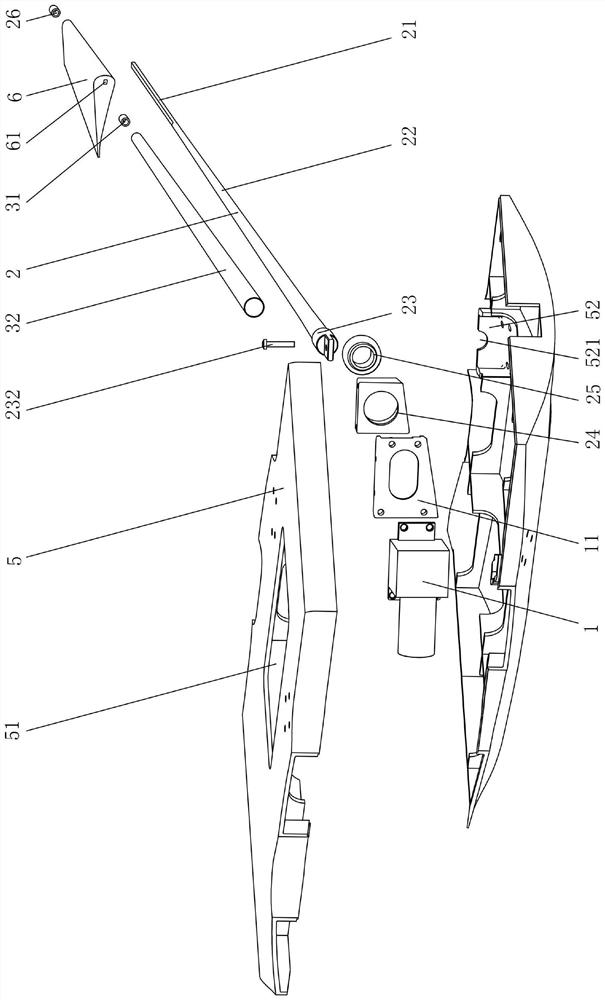

[0036] Such as figure 1 and figure 2 As shown, the integral wing and aileron driving device of the present embodiment is used on the high-speed unmanned aerial vehicle of the integral airfoil, that is, the wing main body 4 and the wing box 5 of the unmanned aerial vehicle adopt an integral molding process, without There is disassembly, no process separation surface, to ensure the smoothness of the lines.

[0037] Including the driving part 1, the transmission assembly 2 and the transmission accommodation cylinder 3, the transmission accommodation cylinder 3 is pre-embedded in the wing main body 4 which is integrally made with the wing box 5 with the opening 51, and is located in the wing main body 4. 6 is installed between the wing box 5 and arranged coaxially with the axis of rotation of the aileron 6 . The pre-embedded transmission housing 3 builds a channel connected between the drive member 1 and the aileron 6 in the wing box 5 during the wing preparation process, provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com