Braille printing machine

A printing machine and braille technology, applied in printing, typewriters, etc., can solve the problems of slow development of braille printing equipment, inconvenient use, complicated process, etc., and achieve the effect of avoiding too little dosage, uniform dosage, and not easy to smooth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

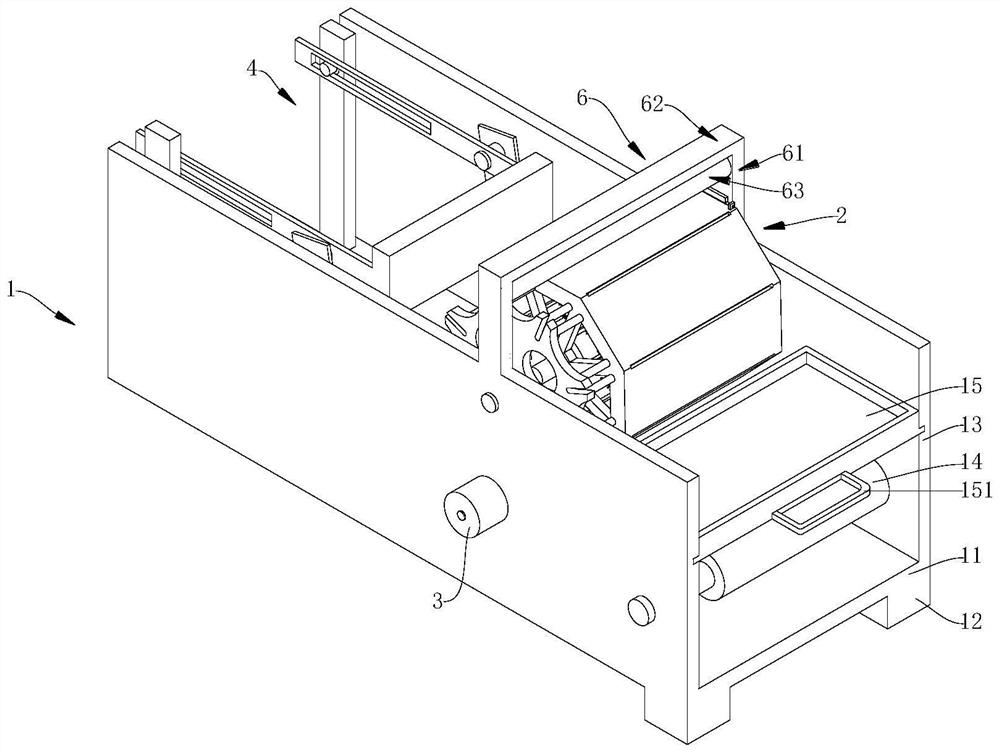

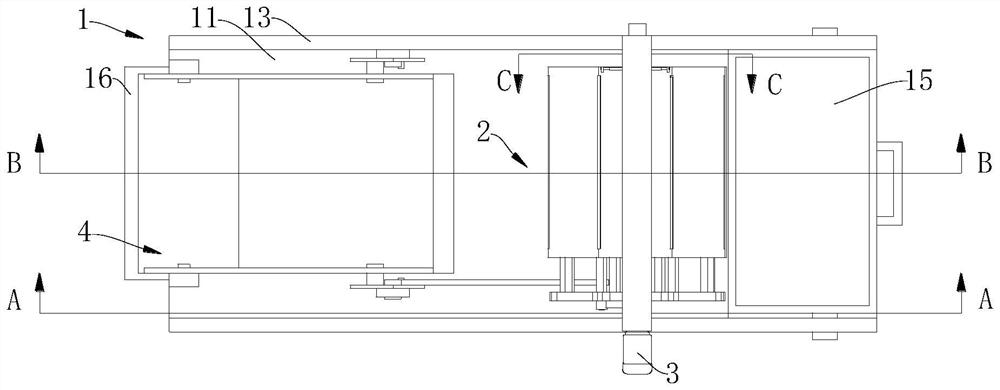

[0036] Such as Figure 1 to Figure 9 As shown, a braille printing machine provided by an embodiment of the present invention includes a frame 1, a transmission device 2, a motor 3 and a printing device 4, wherein:

[0037] Frame 1 comprises base 11, foot base 12, unwinding roller 14 and support plate 13, and the lower end of base 11 is fixedly connected with some foot bases 12, and the upper end of frame 1 is fixedly connected with support plate 13, and one end of base 11 is provided with The printing pool 16, the unwinding roller 14 is rotatably connected to the support plate 13;

[0038] A slot is opened on the support plate 13, and the slot is slidably connected with a material plate 15, and one side of the material plate 15 is fixedly connected with a handle 151;

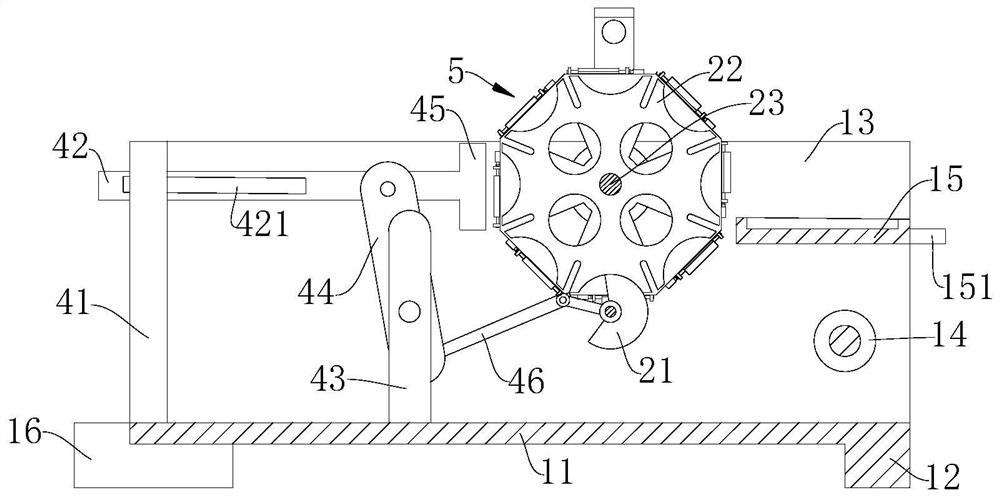

[0039] The transmission device 2 includes a dial 21, a wheel groove disc 22, a fixed shaft 23, a side plate 24 and a motherboard 25, the fixed shaft 23 is fixedly connected to the support plate 13, and the fixe...

specific Embodiment 2

[0047] In embodiment 1, because the printing paper is not clamped, for the convenience of clamping the printing paper, so on the basis of embodiment 2, as Figure 1 to Figure 7 As shown, in this embodiment, a clamping device 5 is also included. The clamping device 5 includes a support base 51, a rotating shaft 52, a pressing plate 53 and a servo motor 54. Both sides of the motherboard 25 are fixedly connected with support bases 51. On the support base 51 A rotating shaft 52 is rotatably connected, a pressing plate 53 is fixedly connected to the rotating shaft 52, a servo motor 54 is fixedly connected to the motherboard 25, the servo motor 54 is connected to the rotating shaft 52 by transmission, and a second protrusion 232 is fixedly connected to the fixed shaft 23. A plurality of switches are evenly and fixedly connected to the side plate 24, and the switch signals are connected to the servo motor 54, and the switches correspond to the servo motor 54 one by one;

[0048] The ...

specific Embodiment 3

[0056] In embodiment 2, because printing paper collection needs extra cutting, it is not convenient to use, so on the basis of embodiment 2, such as Figure 3 to Figure 5 As shown, the transmission device 2 in this embodiment also includes a cutting knife 26 and a limiting block 27. The limiting block 27 is fixedly connected to the side plate 24, and the limiting block 27 is provided with a limiting groove, and the limiting groove is slidably connected with a The cutting knife 26 is fixedly connected with a flange 261 on the cutting knife 26, and the flange 261 is fixedly connected with one end of a spring 262, and the other end of the spring 262 is fixedly connected to the limit block 27, and the spring 262 is in a stretched state. Offer between two motherboards 25 make way groove, make way groove is used for cutting off knife 26 make way.

[0057] Specific working process:

[0058] S1: filling the curing agent in the printing pool 16;

[0059] S2: Clamp the printing paper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com